The Ultimate Guide To Choosing The Best Block Making Machine For Your Business

Are you looking to expand your business with the best block making machine available? Look no further! In this comprehensive guide, we will walk you through everything you need to know to choose the perfect block making machine for your business. Whether you are a seasoned professional or just starting out, this guide has got you covered. Let us help you make the right decision to propel your business to the next level.

- Understanding the Different Types of Block Making Machines

Block making machines are essential equipment for businesses involved in the production of building materials such as concrete blocks, bricks, and tiles. These machines come in various types, each designed for specific purposes and production capacities. In this guide, we will delve into the different types of block making machines available on the market to help you choose the best one for your business.

1. Manual Block Making Machines:

Manual block making machines are operated by hand and are suitable for small-scale production. These machines are simple to use and require minimal maintenance. They are ideal for businesses with limited budget and space constraints. Manual block making machines are commonly used in micro-enterprises and DIY projects.

2. Semi-Automatic Block Making Machines:

Semi-automatic block making machines combine manual operation with automatic functions, such as material feeding and mold filling. These machines offer higher production capacities compared to manual machines and are more suitable for medium-sized businesses. Semi-automatic block making machines are versatile and can produce a variety of concrete products.

3. Fully Automatic Block Making Machines:

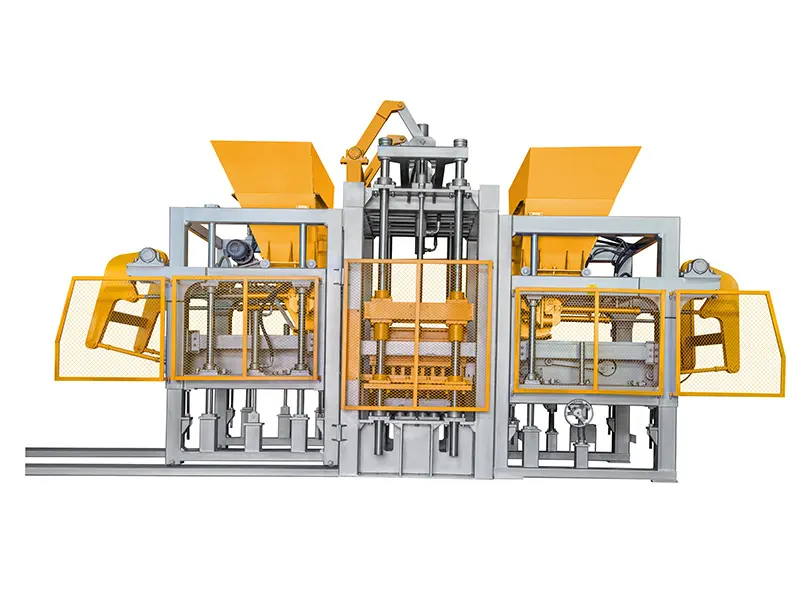

Fully automatic block making machines are equipped with advanced technology and automation systems, minimizing the need for manual intervention. These machines have high production capacities and ensure consistent quality of output. Fully automatic block making machines are ideal for large-scale production facilities that require high efficiency and precision.

4. Hydraulic Block Making Machines:

Hydraulic block making machines operate using hydraulic pressure to compress the raw materials and produce blocks with high strength and durability. These machines are versatile and can produce various types of blocks, including hollow blocks, solid blocks, and interlocking blocks. Hydraulic block making machines are known for their high efficiency and precision.

5. Interlocking Block Making Machines:

Interlocking block making machines are designed to produce blocks that can interlock with each other without the need for mortar. These machines are commonly used for the construction of eco-friendly and earthquake-resistant buildings. Interlocking block making machines are available in manual, semi-automatic, and fully automatic variants, catering to different production requirements.

In conclusion, choosing the best block making machine for your business depends on factors such as production capacity, budget, space constraints, and the types of blocks you intend to produce. By understanding the different types of block making machines available, you can make an informed decision that meets your specific needs and requirements. Invest in a high-quality block making machine to enhance the efficiency and profitability of your business in the construction industry.

- Factors to Consider When Selecting a Block Making Machine

When starting a business in the construction industry, one of the key pieces of equipment you will need is a block making machine. This machine is essential for producing various types of blocks used in building construction, such as concrete blocks, interlocking blocks, and paving blocks. Choosing the right block making machine for your business is crucial, as it can greatly impact the quality and efficiency of your production process.

There are several factors to consider when selecting a block making machine, each of which plays a significant role in determining the suitability of the machine for your business needs. In this comprehensive guide, we will discuss these factors in detail to help you make an informed decision.

The first factor to consider is the type of blocks you plan to produce. Different block making machines are specialized for producing specific types of blocks, so it is important to choose a machine that is capable of producing the blocks you require for your projects. For example, if you are looking to produce interlocking blocks, you will need a machine with the appropriate moulds and specifications for creating these types of blocks.

Another important factor to consider is the production capacity of the block making machine. The production capacity of a machine is determined by factors such as the size of the blocks, the speed of the machine, and the number of blocks it can produce in a given time frame. It is crucial to choose a machine that can meet the production demands of your business to ensure efficient and timely completion of your projects.

Additionally, the quality of the blocks produced by the machine is a critical factor to consider. The quality of the blocks is determined by the design and construction of the machine, as well as the materials used in manufacturing the blocks. It is important to choose a machine that can produce high-quality blocks that meet industry standards and requirements to ensure the durability and integrity of your construction projects.

The cost of the block making machine is also an important consideration. The cost of the machine will vary depending on factors such as the brand, size, capacity, and features of the machine. It is essential to consider your budget and weigh the cost of the machine against its quality, production capacity, and suitability for your business needs.

In conclusion, selecting the best block making machine for your business requires careful consideration of several important factors. By evaluating factors such as the type of blocks, production capacity, quality of the blocks, and cost of the machine, you can make an informed decision that will help enhance the efficiency and productivity of your construction projects. Choose wisely and invest in a high-quality block making machine that will meet the needs of your business and help you achieve success in the construction industry.

- Comparing the Features and Capabilities of Various Block Making Machines

When it comes to starting or expanding a business in the construction industry, investing in the right equipment is crucial. One of the key pieces of machinery that every construction business needs is a reliable block making machine. These machines are used to produce various types of blocks for construction purposes, such as concrete blocks, cement blocks, and interlocking blocks. With the market flooded with different types of block making machines, it can be overwhelming to choose the best one for your business. In this article, we will compare the features and capabilities of various block making machines to help you make an informed decision.

First and foremost, it is important to consider the production capacity of the block making machine. The production capacity of a machine is measured in terms of the number of blocks it can produce in a given period of time. Some machines are designed for small-scale production, while others are capable of producing blocks in large quantities. It is important to assess your business needs and choose a machine that can meet your production requirements efficiently.

Another important factor to consider is the versatility of the block making machine. Some machines are designed to produce a specific type of block, while others can be versatile and produce different types of blocks. If you plan to diversify your product range in the future, it is advisable to choose a versatile machine that can accommodate different types of blocks.

Furthermore, it is important to consider the quality of blocks produced by the machine. The quality of blocks is crucial for the structural integrity of buildings, and therefore, it is important to invest in a machine that can produce high-quality blocks consistently. Look for machines that have features such as precise mold filling, uniform block size, and smooth surface finish.

In addition to the production capacity, versatility, and quality of blocks, it is also important to consider the ease of operation and maintenance of the machine. Look for machines that are user-friendly and easy to operate, as this will save you time and resources in the long run. Similarly, choose a machine that is easy to maintain and has good availability of spare parts.

Lastly, consider the cost of the block making machine. The cost of the machine should be within your budget and should offer good value for money. Take into account not just the initial cost of the machine, but also the cost of operation, maintenance, and replacement parts.

In conclusion, choosing the best block making machine for your business is a crucial decision that requires careful consideration. By comparing the features and capabilities of various machines, you can make an informed decision that will benefit your business in the long run. Consider factors such as production capacity, versatility, quality of blocks, ease of operation and maintenance, and cost before making your final decision. A well-chosen block making machine can significantly enhance the efficiency and productivity of your construction business.

- Assessing the Production Capacity and Efficiency of Block Making Machines

Block making machines are a crucial piece of equipment for businesses in the construction industry. They play a vital role in producing building blocks that are used in a wide range of construction projects, from residential buildings to commercial developments. When it comes to choosing the best block making machine for your business, there are several factors that need to be considered, with assessing the production capacity and efficiency of the machine being one of the most important.

Production capacity refers to the amount of blocks that a machine is capable of producing in a given timeframe. It is essential to choose a machine that has a production capacity that aligns with the needs of your business. If you have a high demand for blocks, you will need a machine with a high production capacity to ensure that you can meet your customers' needs in a timely manner. On the other hand, if your business operates on a smaller scale, a machine with a lower production capacity may be more suitable.

Efficiency is another key factor to consider when choosing a block making machine. An efficient machine will be able to produce blocks quickly and consistently, minimizing downtime and increasing productivity. Look for machines that have features such as automatic block stacking and palletizing, as well as adjustable vibration frequency and amplitude, which can help improve the efficiency of the machine.

In addition to production capacity and efficiency, it is also important to consider the quality of the blocks produced by the machine. The best block making machines will be able to produce high-quality blocks that meet industry standards and regulations. Look for machines that have a robust design, high-quality components, and a reliable control system to ensure that the blocks produced are of a consistent size and shape.

When assessing the production capacity and efficiency of block making machines, it is also important to consider the maintenance requirements of the machine. Choose a machine that is easy to maintain and repair, with readily available spare parts and technical support. Regular maintenance is essential to keep the machine running smoothly and to prolong its lifespan.

Overall, when choosing the best block making machine for your business, it is important to assess the production capacity and efficiency of the machine. By considering these factors, you can ensure that you invest in a machine that meets your business needs and helps you to meet the demands of your customers. Remember to also consider the quality of the blocks produced, as well as the maintenance requirements of the machine, to make an informed decision.

- Making the Final Decision: Finding the Perfect Block Making Machine for Your Business

Block making machines are essential equipment for businesses involved in construction and building projects. These machines are used to produce concrete blocks, which are widely used in construction for building walls, fences, and other structures. Choosing the best block making machine for your business can be a daunting task, as there are many factors to consider. In this article, we will provide a comprehensive guide to help you make the final decision and find the perfect block making machine for your business.

When it comes to selecting a block making machine, there are several key factors to consider. The first step is to determine the type of blocks you need to produce. Different block making machines are designed to produce different types of blocks, such as hollow blocks, solid blocks, interlocking blocks, and paving blocks. You should choose a machine that can produce the type of blocks that are in high demand in your area.

Another important factor to consider is the production capacity of the machine. The production capacity of a block making machine is measured in terms of the number of blocks it can produce per hour. You should choose a machine with a production capacity that meets the demand of your business. If you have a small business with low production requirements, a smaller machine with a lower production capacity may be sufficient. However, if you have a large business with high production requirements, you may need a larger machine with a higher production capacity.

In addition to the type of blocks and production capacity, you should also consider the quality of the blocks produced by the machine. The quality of the blocks is important for ensuring the structural integrity of the buildings and structures constructed with them. Look for a block making machine that produces high-quality blocks that are durable and have consistent dimensions.

When selecting a block making machine for your business, you should also consider the reliability and durability of the machine. A reliable machine will operate smoothly and consistently, with minimal downtime and maintenance issues. Look for a machine from a reputable manufacturer with a proven track record of producing high-quality machines that are built to last.

Furthermore, you should also consider the cost of the block making machine. The cost of the machine includes not only the initial purchase price but also ongoing maintenance and operating costs. It is important to choose a machine that offers good value for money and fits within your budget constraints.

In conclusion, choosing the best block making machine for your business is a crucial decision that can have a significant impact on the success of your construction projects. By considering factors such as the type of blocks, production capacity, quality, reliability, durability, and cost, you can make an informed decision and find the perfect block making machine for your business. Remember to conduct thorough research, compare different machines, and consult with experts before making your final decision. With the right block making machine, you can improve the efficiency and productivity of your business and enhance the quality of the blocks produced.

Conclusion

In conclusion, selecting the best block making machine for your business is a crucial decision that can impact the overall success and efficiency of your operations. With 18 years of experience in the industry, we understand the importance of choosing a machine that meets your specific needs and requirements. By following the ultimate guide outlined in this article, you can confidently make an informed decision that will drive growth and productivity for your business. Remember, investing in the right block making machine is an investment in the future of your company.