Green Transformation in the Construction Industry: Development Prospects of Environmentally Friendly Block-Making Machines

WEGreen Transformation in the Construction Industry: Development Prospects of Environmentally Friendly Block-Making Machines

Abstract:

With increasing global attention to climate change and resource depletion, the green transformation of the construction industry has become an irreversible trend of the times. As a key link in building material production, the innovation of block-making equipment is crucial for reducing emissions and energy consumption in the industry. Furthermore, using SWOT analysis, the paper delves into the market opportunities, technical challenges, and external risks they face. Finally, from the perspective of integrating the circular economy and Industry 4.0, it outlines future development trends and proposes recommendations for promoting industrial upgrading through technological innovation and policy synergy, aiming to provide insights for equipment manufacturers, building material enterprises, and industry decision-makers.

Keywords: Green building; Block-making machine; Environmental equipment; Solid waste utilization; Circular economy; Development prospects

1. Introduction

The construction industry is one of the primary sources of global resource consumption and carbon emissions. Traditional block production relies on natural aggregates and high-temperature sintering, resulting in high energy consumption and significant pollution. Driven by global "dual-carbon" goals (carbon peaking and carbon neutrality) and sustainable development agendas, the green transformation of the construction industry is imminent. This transformation is reflected not only in building design and operation but also deeply permeates the upstream stages of building material production. Environmentally friendly block-making machines, as core equipment capable of producing green blocks using industrial solid waste (such as fly ash, slag, and construction waste), are transitioning from marginal innovation to center stage. This paper systematically explores their development logic, technological pathways, and market prospects within the context of the industry's green transformation.

2. Drivers of Green Transformation in the Construction Industry and Requirements for Equipment

2.1 Policy and Regulatory Drivers

Governments worldwide have successively introduced stringent building energy efficiency standards and carbon emission regulations (e.g., China’s "14th Five-Year Plan for Building Energy Efficiency and Green Buildings" and the European Union’s "Green Deal"). Simultaneously, green building rating systems (such as LEED, BREEAM, and China’s Three-Star Green Building Standard) incorporate the environmental attributes of building materials into their scoring, directly stimulating market demand for green blocks.

2.2 Market and Economic Drivers

Investors and consumers are increasingly environmentally conscious, favoring buildings with green certifications. Additionally, the maturity of carbon trading markets enables producers using solid waste materials to potentially earn carbon quota benefits, thereby reducing production costs.

2.3 Resource and Environmental Pressures

Natural sand and gravel resources are becoming increasingly scarce, with rising prices, while industrial solid waste accumulates, incurring high disposal costs. This contradiction has spurred the "turning waste into treasure" circular economy model, creating rigid demand for production equipment capable of processing diverse waste materials.

In summary, the green transformation of the industry requires block production equipment to evolve toward "environmental friendliness": that is, to possess raw material adaptability, low-carbon production, and process intelligence.**

3. The Essence, Technical Features, and Advantages of Environmentally Friendly Block-Making Machines

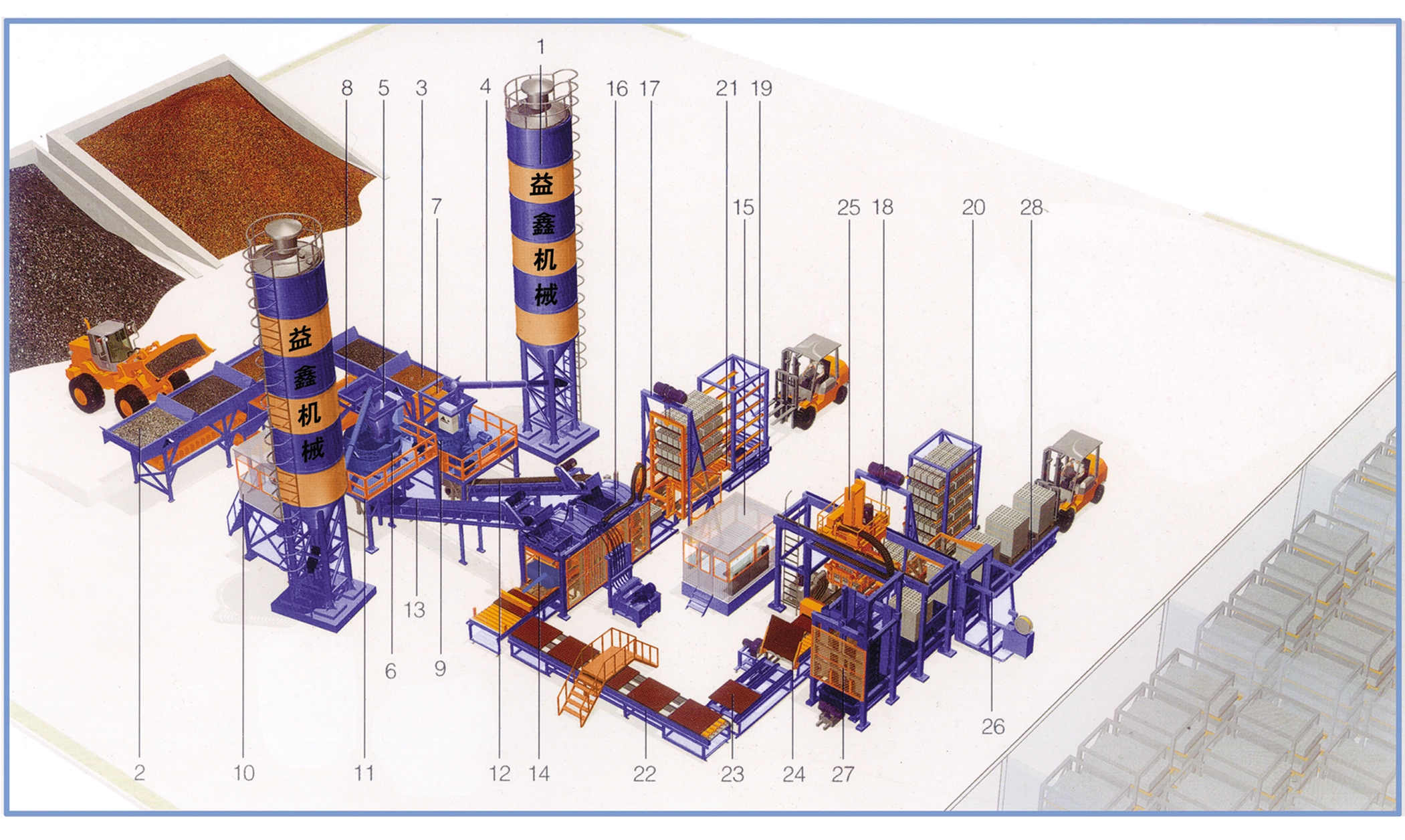

Environmentally friendly block-making machines are not a single model but rather a category of technologically integrated equipment systems designed to meet green production goals.

3.1 Core Essence

Using industrial solid waste as the primary raw material, these machines produce blocks that meet building performance requirements through physical or chemical molding processes (such as high-pressure vibration and steam curing), while achieving energy savings and minimizing negative environmental impacts.

3.2 Key Technical Features

- Raw Material Adaptation and Preprocessing System: Enhanced feeding, metering, and mixing systems capable of handling fly ash, crushed construction waste, and other materials with varying particle sizes and moisture levels, ensuring raw material homogeneity.

- Energy-Saving Drive and Hydraulic System:Utilization of variable-frequency motors and energy-recovery hydraulic systems, achieving energy savings of 20%–30% compared to traditional equipment.

- Low-Noise and Low-Emission Design: Optimized mechanical structures to reduce vibration noise; enclosed production to minimize dust dispersion.

- Intelligent Control System: Integration of PLC and IoT sensors for real-time monitoring of raw material ratios, molding pressure, and curing temperature and humidity, enabling product quality traceability and production efficiency optimization.

3.3 Main Advantages

- Environmental Benefits: Absorbs large amounts of solid waste, reduces natural resource extraction, and minimizes pollution from landfill disposal.

- Economic Benefits:

Lowers raw material costs, qualifies for environmental policy subsidies, and offers potential market premium for products.

- Social Benefits: Promotes the greening of the industrial chain and supports urban mining development and waste-free city initiatives.

4. SWOT Analysis of the Development Prospects of Environmentally Friendly Block-Making Machines

- Strengths: Aligns with policy direction, gradual maturation of core technologies, and advantages in full lifecycle costs.

- Weaknesses: Higher initial investment compared to traditional equipment, higher technical requirements for operation and maintenance personnel, and fluctuations in the performance of some solid waste materials affecting product consistency.

- Opportunities: Global trend toward green infrastructure, significant demand for urban renovation in emerging markets, and new possibilities for equipment intelligence enabled by digital twin and artificial intelligence technologies.

- Threats: Dependency on traditional paths and low-price competition, challenges in equipment versatility due to regional differences in solid waste composition, and uncertainties in the enforcement of environmental policies.

5. Future Development Trends and Recommendations

5.1 Development Trends

1. Customization and Modularization: Provides tailored raw material processing solutions and modular main units to address the specific characteristics of solid waste in different regions.

2. Intelligent Production Lines: Deep integration with Manufacturing Execution Systems (MES) and cloud platforms to achieve remote operation and maintenance, predictive maintenance, and precise carbon emission measurement.

3. High-Performance Products: Equipment evolves toward producing high-value-added blocks (such as self-insulating, decorative-integrated, and high-strength structural blocks), enhancing the value of the industrial chain.

5.2 Development Recommendations

1. For Government: Increase research and development subsidies and procurement preferences for environmental equipment, establish standards for solid waste raw materials, and stabilize upstream supply chains.

2. For Enterprises: Equipment manufacturers should strengthen collaboration with research institutions to overcome key component technologies; building material producers should focus on long-term benefits and actively update green production capacities.

3. For the Industry: Establish technical specifications and certification systems for the production and application of green blocks, fostering a healthy industrial ecosystem.

6. Conclusion

The green transformation of the construction industry is a profound systemic change. As a critical link between "waste" and "green building materials," the development prospects of environmentally friendly block-making machines are closely tied to the sustainable future of the industry. Despite facing cost and technical challenges, driven by strong policy, market, and environmental demands, continuous technological innovation, cost optimization, and industrial collaboration will inevitably transform environmentally friendly block-making machines from a current technological option into the mainstream standard for future block production. This will provide a solid equipment foundation for building a resource-efficient and environmentally friendly society. Their development is not only an upgrade in manufacturing but also a key practice in realizing the circular economy concept within the construction sector.

WEB: www.yixinblockmachine.cn TEL: 0086-595-2296 3811