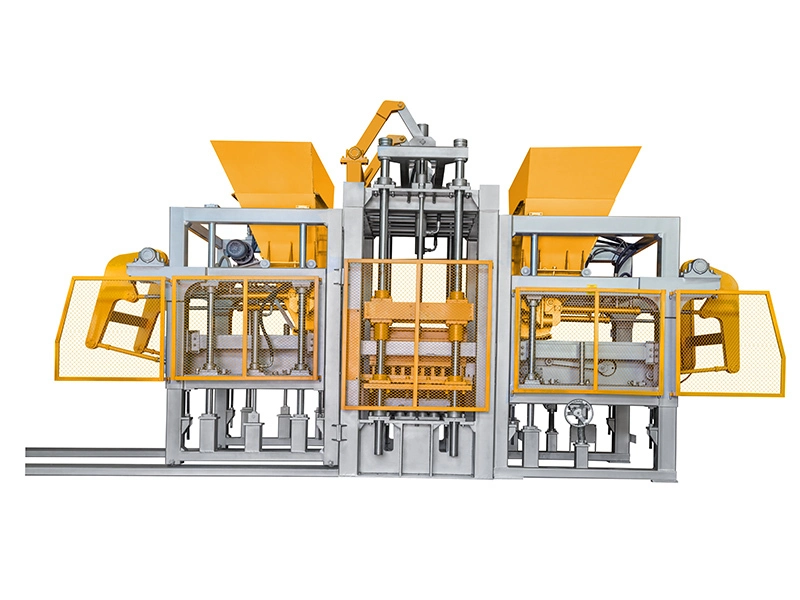

Yixin Machinery Brand Authorization Fully Set Premium Quality Heavy Duty Concrete Block Making Machine QT15-15

Place of Origin: China

Minimum order quantity: 1set

Color: Blue and yellow can be customzied

Material Science: Q235 Steel ,handox steel

Packing: Film

Delivery time: 25 working days

Model: QT15-15 Heavy Duty

Transaction mode: TT or 100%LC

Discharge port: Xiamen port

TECH DATA

|

The QT15-15 block making machine utilizes a unique forming process where the bricks are shaped by beating. In this system, the static table is precisely set 3 mm lower than the dynamic table. This specific height difference is crucial, as it ensures the concrete mixture is compacted with significant force and high pressure during each cycle. The result is the production of exceptionally dense and high-strength bricks. This superior density makes the machine ideally suited for manufacturing premium colored bricks, where a flawless surface finish is critical, and for producing high-grade, heavy-duty bricks that meet stringent quality standards. The process guarantees excellent structural integrity and a consistent, high-quality final product.

The automatic pallet provider integrated into the Yixin QT15-15 block making machine is engineered for high-volume, continuous production environments. Its primary application is in large-scale construction material factories and industrial brick yards that operate on a 24/7 basis. This system automatically feeds pallets into the machine, ensuring a seamless, non-stop workflow for producing high-density concrete blocks, pavers, and other interlocking bricks. By eliminating manual pallet handling, it significantly boosts production output and efficiency while reducing labor costs and the risk of workplace injuries. The automatic provider maintains a consistent cycle time, which is crucial for synchronized production lines where the blocks are directly transferred to curing racks or automated stacking systems.

The pressure meter on the Yixin QT15-15 concrete block making machine is a critical component for precise operational control. Its primary function is to monitor and regulate the air pressure within the system's airbag. Proper adjustment via this meter is essential for setting the optimal compaction force during the block molding process. This ensures that each concrete block produced achieves a uniform high density, superior structural integrity, and a consistent premium finish. Accurate pressure control directly contributes to the machine's heavy-duty performance, enhancing production efficiency and reducing material waste. The meter provides a clear visual reference, allowing operators to maintain the correct settings for reliable and high-quality output.

|

|---|

|

Product Classification Description : Yixin Machinery Brand Authorization Fully Set Premium Quality Heavy Duty Concrete Block Making Machine QT15-15 Refer to : The Yixin QT15-15 is a heavy-duty, fully automatic cement block making machine designed for high-volume production. It features a robust structure for exceptional durability and stable operation. This model efficiently produces various cement blocks, pavers, and bricks with consistent quality and high density. The automated system ensures precise control over the entire process, from mixing and feeding to molding and palletizing. Customizable to meet specific production needs, it is an ideal solution for large-scale construction projects and industrial block manufacturing, offering both reliability and superior performance.

|

|---|

|

1.How long does it take to make a block with the Yixin Machinery Brand Authorization Fully Set Premium Quality Heavy Duty Concrete Block Making Machine QT15-15 ? With a cycle time of 13-25 seconds, this heavy-duty multi-function machine can produce a high volume of blocks efficiently and quickly. 2.How many solid blocks can the Yixin Machinery Brand Authorization Fully Set Premium Quality Heavy Duty Concrete Block Making Machine QT15-15 produce per hour? This high-performance machine can produce an impressive 20625 solid blocks per hour, making it a highly efficient and productive option for block making. |

|---|

|

|

|---|