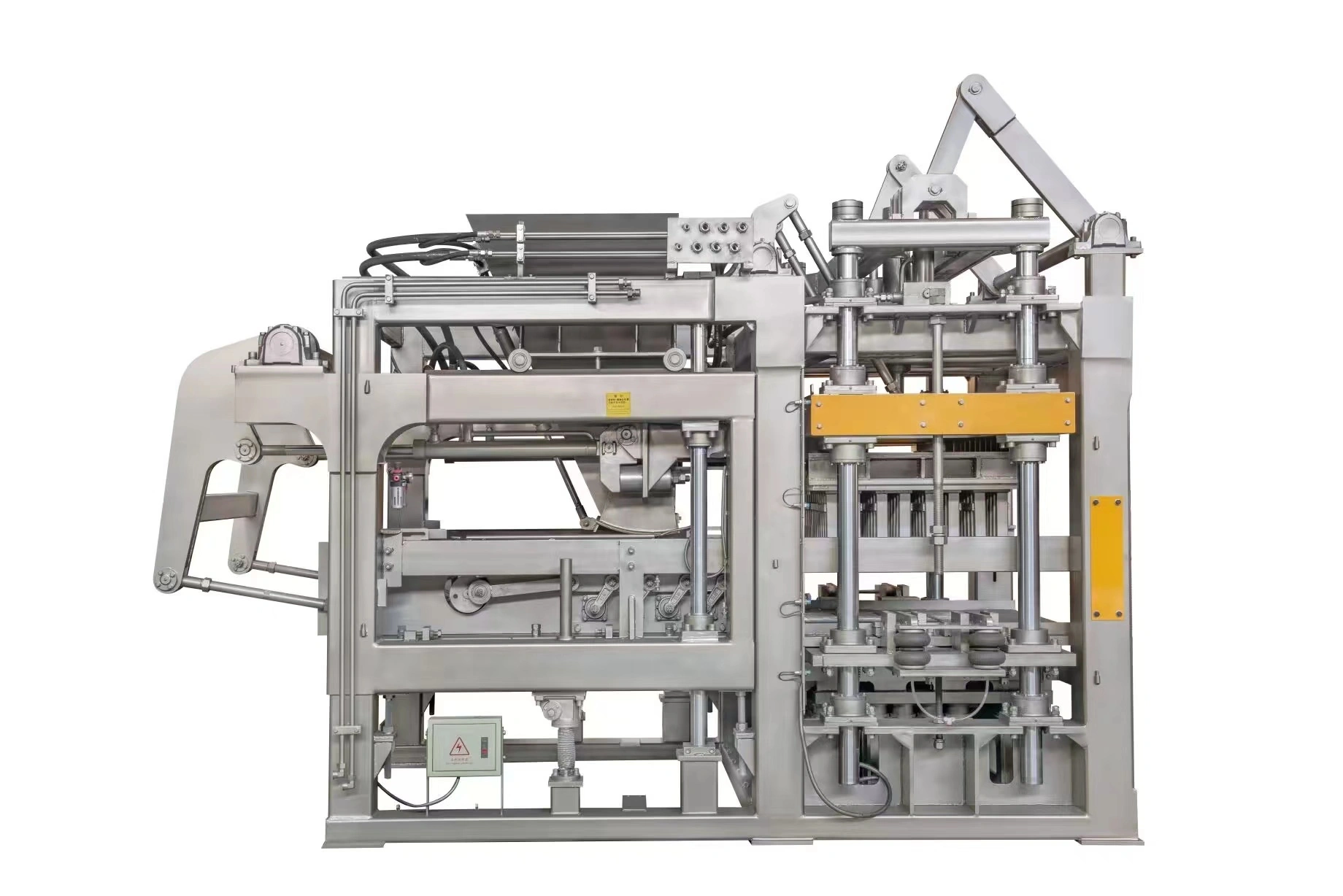

Yixin Machinery Brand Authorization Premium Quality Automatic Heavy Duty Hollow Block Making Machine QT6-15

Place of Origin: China

Minimum order quantity: 1set

Color: Silver and yellow can be customzied

Material Science: Q235 Steel ,handox steel

Packing: Film

Delivery time: 25 working days

Model: QT6-15 heavy duty

Transaction mode: TT or 100%LC

Discharge port: Xiamen port

Tech Data

| ITEM | QT6-15HD |

|---|---|

| VIBRATION FREQUENCY | 3800-4500(T/S) |

| CYCLE TIME |

15-25(S) |

| VIBRATION FORCE | 95(KN) |

| VATED PRESSURE | 21(MPA) |

| POWER | 34.54(KW) |

| VIBRATION TYPE |

VIBRATION& PRESS |

|

The long guide sleeves in the QT6-15 block making machine are fundamental for high-volume, precision production. In a busy plant, where the machine operates for extended cycles, these sleeves ensure the massive mold head moves with absolute vertical stability, preventing misalignment that could cause defective blocks or damage. The innovative guiding bush, designed to be raised and lowered, actively combats wear. By periodically adjusting its position, operators distribute wear evenly across its surface. This dramatically extends the service intervals for these critical components, reducing downtime and maintenance costs, thereby ensuring consistent, high-quality block output and maximizing the machine's operational lifespan in a demanding industrial environment.

The wear-resistant strips on the Yixin QT6-15 block making machine are designed for scenarios demanding high-volume, continuous production of concrete blocks and bricks. In such intensive operations, machinery components are subject to constant friction and wear. The key advantage of these strips is their design for convenient replacement and maintenance. When wear occurs, operators can quickly swap out the individual strips without the need for extensive downtime or complex procedures. This is significantly more convenient than dealing with a single, large integral cast steel part, which would be heavier, more difficult to handle, and require more time and labor to replace. This feature directly translates to reduced maintenance windows, lower labor costs, and maximized machine uptime, ensuring consistent output in a busy construction or prefabrication plant.

The advance and retreat cushion pad in the Yixin QT6-15 block making machine is a critical component for ensuring smooth and stable mold movement. Its primary application is during the concrete compaction and mold stripping cycles. As the mold advances to fill with concrete, the cushion pad absorbs the initial impact, ensuring a precise and jolt-free start to the compaction process. Upon completion, it then controls the mold's retreat, facilitating a clean and shock-free separation of the freshly formed hollow blocks from the mold cavity. This precise damping action is essential for protecting the machine's structural integrity from stress peaks, significantly reducing vibration and noise.

|

|---|

|

Product Classification Description:Yixin Machinery Brand Authorization Premium Quality Automatic Heavy Duty Hollow Block Making Machine QT6-15 Refer to: The Yixin QT6-15 is a fully automatic, heavy-duty block making machine engineered for large-scale industrial production. Its primary application is in dedicated brick yards and construction material plants that mass-produce high-strength hollow blocks, paver blocks, and other standard or custom concrete products. The machine's high degree of automation, with a robust hydraulic system and precision controls, ensures consistent output and superior product quality with minimal manual intervention. It is perfectly suited for major infrastructure projects, urban development initiatives, and supplying construction companies with a reliable, high-volume source of premium building materials. The QT6-15 is the ideal solution for manufacturers seeking to optimize efficiency, maximize output, and establish a strong supply chain for the construction industry.

|

|---|

| 1.What is the vibration frequency for Yixin Machinery Brand Authorization Premium Quality Automatic Heavy Duty Hollow Block Making Machine QT6-15 ? The vibration frequency is 3800-4500(T/S) , making it highly efficient for producing curbstone and interlocking blocks. Efficient and fast production for all your construction needs.

2.How many liter hydraulic oil used?

68 degree hydraulic oil 600L request. 3.What is the estimated date of shipment for Yixin Machinery Brand Authorization Premium Quality Automatic Heavy Duty Hollow Block Making Machine QT6-15 after mold confirmation?

|

|---|

|

|

|---|