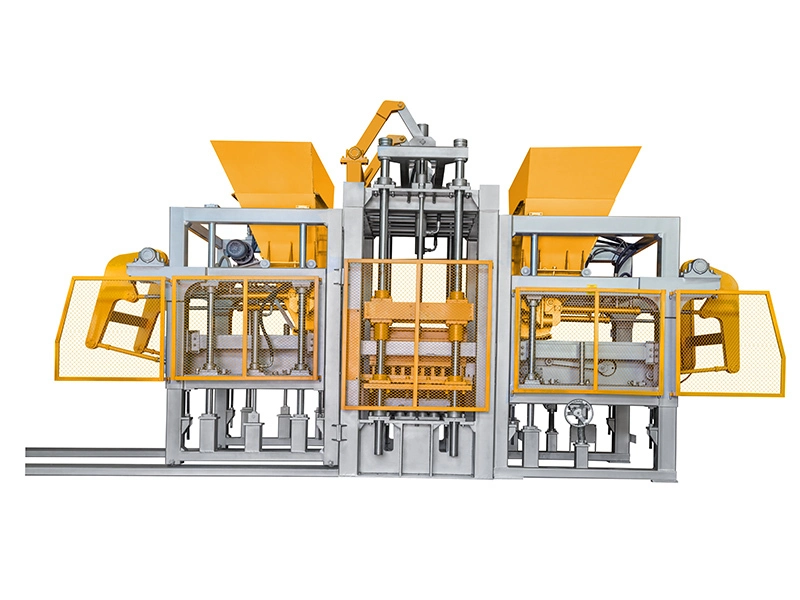

Yixin Machinery Energy—Saving Fully Set Premium Heavy Duty Curbstone Paver Block Making Machine QT15-15

Place of Origin: China

Minimum order quantity: 1set

Color: Blue and yellow can be customzied

Material Science: Q235 Steel ,handox steel

Packing: Film

Delivery time: 25 working days

Model: QT15-15 Heavy Duty

Transaction mode: TT or 100%LC

Discharge port: Xiamen port

TECH DATA

|

The color mixer system of the Yixin Machinery QT15-15 block making machine ensures uniform and vibrant color distribution for high-quality curbstones. It features an automated dosing mechanism for precise pigment measurement, reducing material waste. The robust mixing blades guarantee thorough blending of colors with consistent results. Compatible with various pigments, it supports customizable color options. The system is designed for easy cleaning and maintenance, enhancing operational efficiency. Its durable construction ensures long-term reliability in heavy-duty production environments. The user-friendly interface allows for simple adjustments and real-time monitoring. This system significantly improves product aesthetics while maintaining production speed and quality.

The flexible feeding arm on the Yixin Machinery QT15-15 block making machine ensures smooth and stable material cart pushing, enhancing production efficiency. Ideal for heavy-duty curbstone and paver block manufacturing, it minimizes manual intervention while maintaining consistent material flow. Suitable for large-scale construction projects, this feature reduces downtime and improves precision in block formation. The robust design ensures durability even in high-intensity operations, making it a reliable choice for industrial applications. Its adaptability to various material types further optimizes workflow, ensuring seamless operation in diverse production environments.

The wear-resistant strips on the Yixin Machinery QT15-15 block making machine are designed for easy replacement and maintenance, making them ideal for high-volume production environments. Unlike integral cast steel, these strips reduce downtime during repairs, ensuring continuous operation in demanding construction projects. Their durability and user-friendly design enhance efficiency, making them a practical choice for manufacturers prioritizing cost-effective and low-maintenance solutions. The quick-replacement feature is especially beneficial for businesses seeking to minimize operational disruptions.

|

|---|

|

Product Classification Description : Yixin Machinery Energy—Saving Fully Set Premium Heavy Duty Curbstone Paver Block Making Machine QT15-15 Refer to : The Yixin Machinery QT15-15 is an energy-saving, fully automatic heavy-duty block making machine designed for producing high-quality curbstones and pavers. It features a robust structure, durable components, and advanced hydraulic systems for efficient operation. The machine offers a large production capacity with low energy consumption, ensuring cost-effectiveness. Its precision molding technology guarantees consistent product quality. The QT15-15 is user-friendly, with easy maintenance and a compact design for space efficiency. Ideal for large-scale construction projects, it supports various raw materials, including concrete and fly ash, making it versatile and environmentally friendly.

|

|---|

|

1.How long does it take to make a block with the Yixin Machinery Energy—Saving Fully Set Premium Heavy Duty Curbstone Paver Block Making Machine QT15-15 ? With a cycle time of 13-25 seconds, this heavy-duty multi-function machine can produce a high volume of blocks efficiently and quickly. 2.How many solid blocks can the Yixin Machinery Energy—Saving Fully Set Premium Heavy Duty Curbstone Paver Block Making Machine QT15-15 produce per hour? This high-performance machine can produce an impressive 20625 solid blocks per hour, making it a highly efficient and productive option for block making. |

|---|

|

1.Adopting the best international design process, advanced technology. 2.Crank arm fabrication, fast and uniform. 3.Guide column dynamic demoulding mechanism, demoulding parallel and more accurate. 4.Suspended material cart, fabrication faster and more durable. 5.The vibration box adopts a variety of linkage vibrations, with a large molding area and high product density. 6.Servo frequency modulation drive control can be selected, with fast vibration start, short molding cycle and more accurate control. 7.Optional intelligent remote control electronic control can grasp the equipment operation status in real time, remotely control, operate, judge and solve equipment failures; online monitoring of the equipment operation status, online prediction and diagnosis of the equipment application operation and status. |

|---|