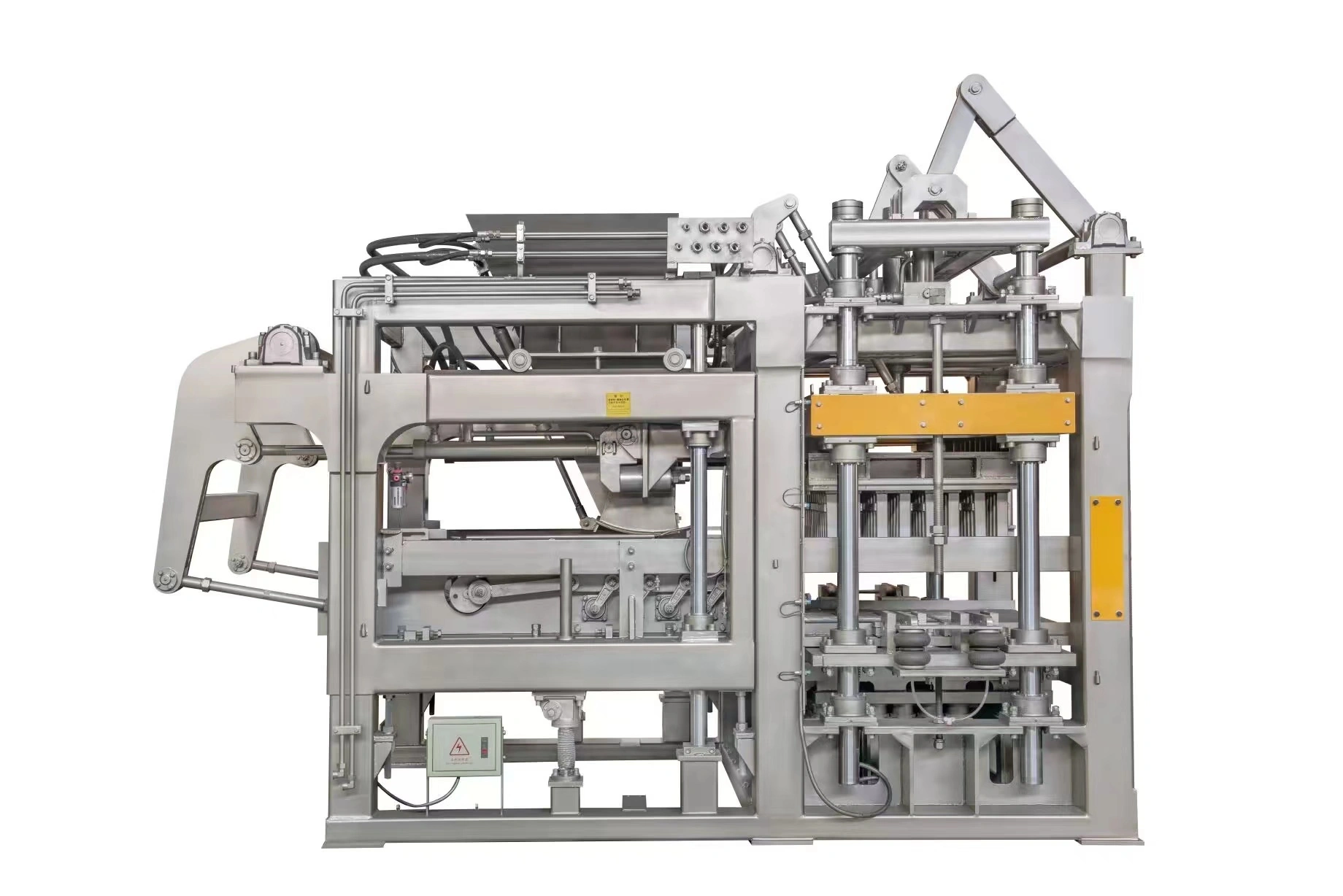

Yixin Machinery Energy-Saving Heavy Duty Concrete Block Making Machine Manufacture QT10-15

Place of Origin: China

Minimum order quantity: 1set

Color: Silver and yellow can be customzied

Material Science: Q235 Steel ,handox steel

Packing: Film

Delivery time: 25 working days

Model: QT10-15 heavy duty

Transaction mode: TT or 100%LC

Discharge port: Xiamen port

Tech Data

|

The QT10-15 block making machine by Yixin Machinery features long guide sleeves for enhanced stability and balance during operation. The guiding bush is adjustable, allowing it to be raised or lowered to minimize wear and prolong service life. This design ensures smooth and precise movement, reducing maintenance needs and improving efficiency. The durable construction supports heavy-duty performance, making it ideal for high-volume concrete block production. Energy-saving technology further enhances its cost-effectiveness and environmental friendliness. A reliable choice for industrial block manufacturing.

The QT10-15 from Yixin Machinery features a dynamic and static vibration table system for high-density brick formation. The static table is set 3 mm lower than the dynamic table, ensuring effective compaction through beating. This design produces dense, uniform bricks ideal for colored and high-strength applications. The machine excels in energy efficiency and heavy-duty performance, making it suitable for large-scale production. Its precision vibration mechanism enhances brick quality, durability, and surface finish, meeting industrial standards for premium concrete blocks.

The QT10-15 Energy-Saving Heavy Duty Concrete Block Making Machine by Yixin Machinery features advanced demolding synchronization technology, ensuring faster and more stable operation. Ideal for large-scale construction projects, it efficiently produces high-quality concrete blocks with minimal downtime. Its robust design and energy-saving capabilities make it suitable for continuous production in harsh environments. The synchronized demolding system enhances precision, reducing material waste and improving productivity. Perfect for manufacturers seeking reliable, high-output block production with consistent results. This machine is a cost-effective solution for modern construction demands.

|

|---|

|

Product Classification Description: Yixin Machinery Energy-Saving Heavy Duty Concrete Block Making Machine Manufacture QT10-15 Refer to : The QT10-15 Energy-Saving Heavy Duty Concrete Block Making Machine by Yixin Machinery is ideal for large-scale construction projects requiring high efficiency and durability. It is suitable for producing hollow blocks, solid bricks, and pavers, widely used in residential, commercial, and industrial building applications. Its energy-saving design reduces operational costs, making it perfect for sustainable construction. The machine is also favored in infrastructure projects like roads and bridges due to its robust performance and consistent output quality. Easy to operate and maintain, it meets the demands of modern construction while minimizing environmental impact.

|

|---|

|

1.How many days to change vibration box oil ,what kind of oil can be used inside?

The hydraulic oil 68 degree can be used, the amount is from bottom 3cm. Strongly suggest 1 month change one time oil 2. How many hollow blocks can the Yixin Machinery QT10-15 produce per hour?

The QT10-15 can produce 1980 hollow blocks per hour, ensuring high productivity for your pavement block making needs. |

|---|

|

1.Adopting the best international design process, advanced technology. 2.Crank arm fabrication, fast and uniform. 3.Guide column dynamic demoulding mechanism, demoulding parallel and more accurate. 4.Suspended material cart, fabrication faster and more durable. 5.The vibration box adopts a variety of linkage vibrations, with a large molding area and high product density. 6.Servo frequency modulation drive control can be selected, with fast vibration start, short molding cycle and more accurate control. 7.Optional intelligent remote control electronic control can grasp the equipment operation status in real time, remotely control, operate, judge and solve equipment failures; online monitoring of the equipment operation status, online prediction and diagnosis of the equipment application operation and status. |

|---|