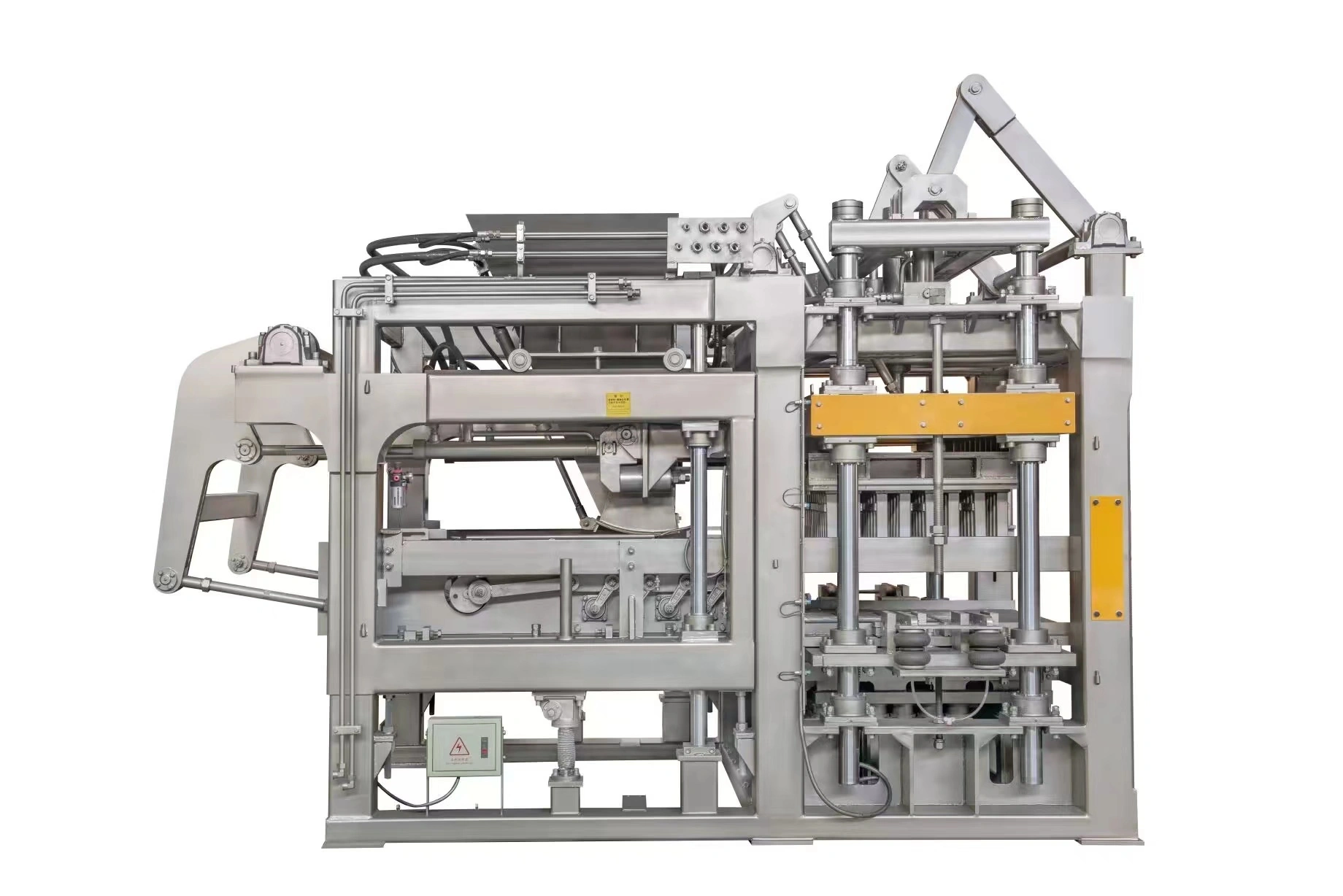

Yixin Machinery Energy-Saving Heavy Duty Hydraulic Pavement Block Manking Machine QT10-15

Place of Origin: China

Minimum order quantity: 1set

Color: Silver and yellow can be customzied

Material Science: Q235 Steel ,handox steel

Packing: Film

Delivery time: 25 working days

Model: QT10-15 heavy duty

Transaction mode: TT or 100%LC

Discharge port: Xiamen port

TECH DATA

|

Yixin Machinery Energy-Saving Heavy Duty Hydraulic Pavement Block Manking Machine QT10-15 features a Germany-brand Continental airbag with a precision pressure control system, ensuring stable and efficient operation. The airbag provides additional force to the mold, enhancing block density and quality. Operators can easily change and fix molds, reducing downtime and improving productivity. Designed for durability and user convenience, this machine delivers reliable performance for high-volume curbstone and block production.

Yixin Machinery Energy-Saving Heavy Duty Hydraulic Pavement Block Manking Machine QT10-15 ensures precise brick formation with its advanced vibration table technology. During the molding process, the vibrating table evenly distributes force, enhancing compaction and improving brick density. This results in uniformly shaped, high-quality curbstone blocks with smooth surfaces and consistent dimensions. The machine's efficient vibration system minimizes voids, ensuring durability and structural integrity.

|

|---|

|

Product Classification Description:Yixin Machinery Energy-Saving Heavy Duty Hydraulic Pavement Block Manking Machine QT10-15 Refer to : Yixin Machinery Energy-Saving Heavy Duty Hydraulic Pavement Block Manking Machine QT10-15 is designed for high-efficiency production of curbstone blocks and other concrete products. It features a fully automatic operation system, ensuring precise and consistent output. With a production capacity of 12-15 blocks per cycle, it is ideal for large-scale projects. The machine boasts robust construction, low maintenance, and energy efficiency. Its user-friendly interface allows easy adjustment of block size and shape.

|

|---|

|

1.Can this machine make my bricks or bricks of other sizes? We will design and make mold according to customer's drawing. 2.What is the vibration frequency of this machine? 3800-4500(r/min)

|

|---|