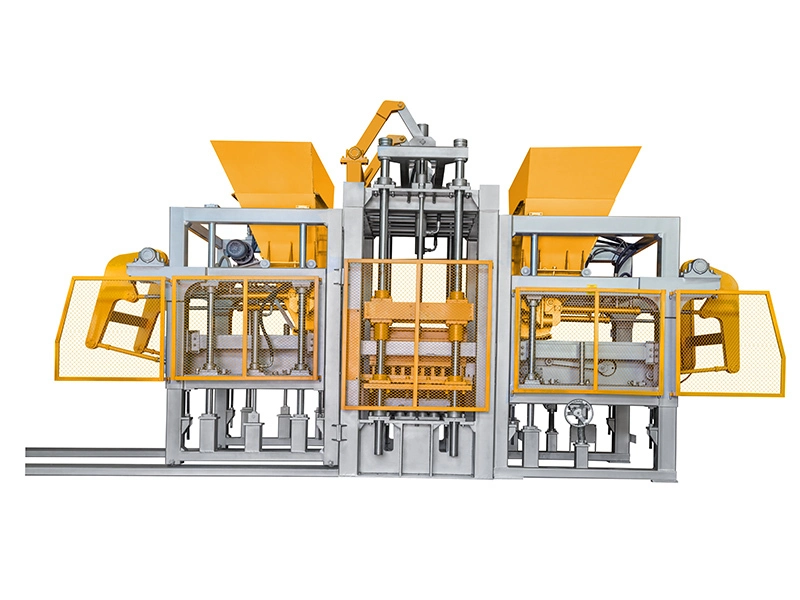

Yixin Machinery Exclusive Price High Standard Heavy Duty PC Stone Block Making Machine QT12-15

Place of Origin: China

Minimum order quantity: 1set

Color: Silver and yellow can be customzied

Material Science: Q235 Steel ,handox steel

Packing: Film

Delivery time: 25 working days

Model: QT12-15 heavy duty

Transaction mode: TT or 100%LC

Discharge port: Xiamen port

Tech Data

|

The long guide sleeves in the Yixin QT12-15 block making machine are crucial for ensuring operational stability and balance during high-volume production. These sleeves provide precise vertical alignment for the mold and press head, which is essential for producing consistently uniform, high-quality concrete blocks and pavers. The unique feature of adjustable guiding bushes allows them to be raised or lowered. This adjustability distributes wear more evenly across the component surface, significantly reducing friction and abrasion. Consequently, this design greatly extends the service life of critical parts, minimizes downtime for maintenance, and lowers long-term operating costs, making it ideal for demanding, continuous-duty applications.

The flexible feeding arm on the Yixin QT12-15 block making machine is designed for versatile production scenarios. It efficiently handles a varied mix of raw materials, such as concrete, cement, and aggregates, with different consistencies and feed rates. This adaptability is crucial for operations that produce multiple block types or switch between recipes frequently, minimizing downtime for adjustments. The arm ensures a consistent and uniform fill of the mold chamber, which is vital for manufacturing high-density, precision blocks. This feature is particularly beneficial in plants where maximizing output and maintaining product quality with a non-homogeneous material supply are key operational challenges.

The dynamic and static vibration table of the Yixin QT12-15 block making machine is engineered for high-performance production scenarios. Its dual-mode system is essential for manufacturing a wide range of high-density, precision concrete products. In static mode, it ensures the thorough compaction of hollow blocks and interlocking pavers, eliminating internal voids for superior structural integrity. The dynamic mode is ideal for producing solid bricks and kerbstones, where high-frequency vibration achieves maximum compaction and optimal strength. This versatility allows operators to switch between product lines effortlessly, making it a cornerstone machine for large-scale construction projects, industrial yards, and precast concrete plants requiring consistent, top-tier output with minimal material waste.

|

|---|

|

Product Classification Description: Yixin Machinery Exclusive Price High Standard Heavy Duty PC Stone Block Making Machine QT12-15 Refer to : The QT12-15 block making machine from Yixin Machinery is engineered for large-scale industrial production, making it an ideal solution for major construction projects and high-output manufacturing plants. Its robust heavy-duty design ensures reliable, continuous operation for producing a wide array of concrete products, including standard blocks, hollow bricks, and interlocking pavers. The machine's distinctive feature is its ability to create vibrantly colored blocks, which is perfect for supplying architectural and landscaping projects that require both structural integrity and aesthetic appeal. This model is best suited for established factories and professional builders who need to meet substantial market demand with consistent, high-standard quality and efficient output.

|

|---|

|

1.How many days to change vibration box oil ,what kind of oil can be used inside?

The hydraulic oil 68 degree can be used, the amount is from bottom 3cm. Strongly suggest 1 month change one time oil 2. How many hollow blocks can the Yixin Machinery QT12-15 produce per hour?

The QT12-15 can produce 2376 hollow blocks per hour, ensuring high productivity for your pavement block making needs. |

|---|

|

|

|---|