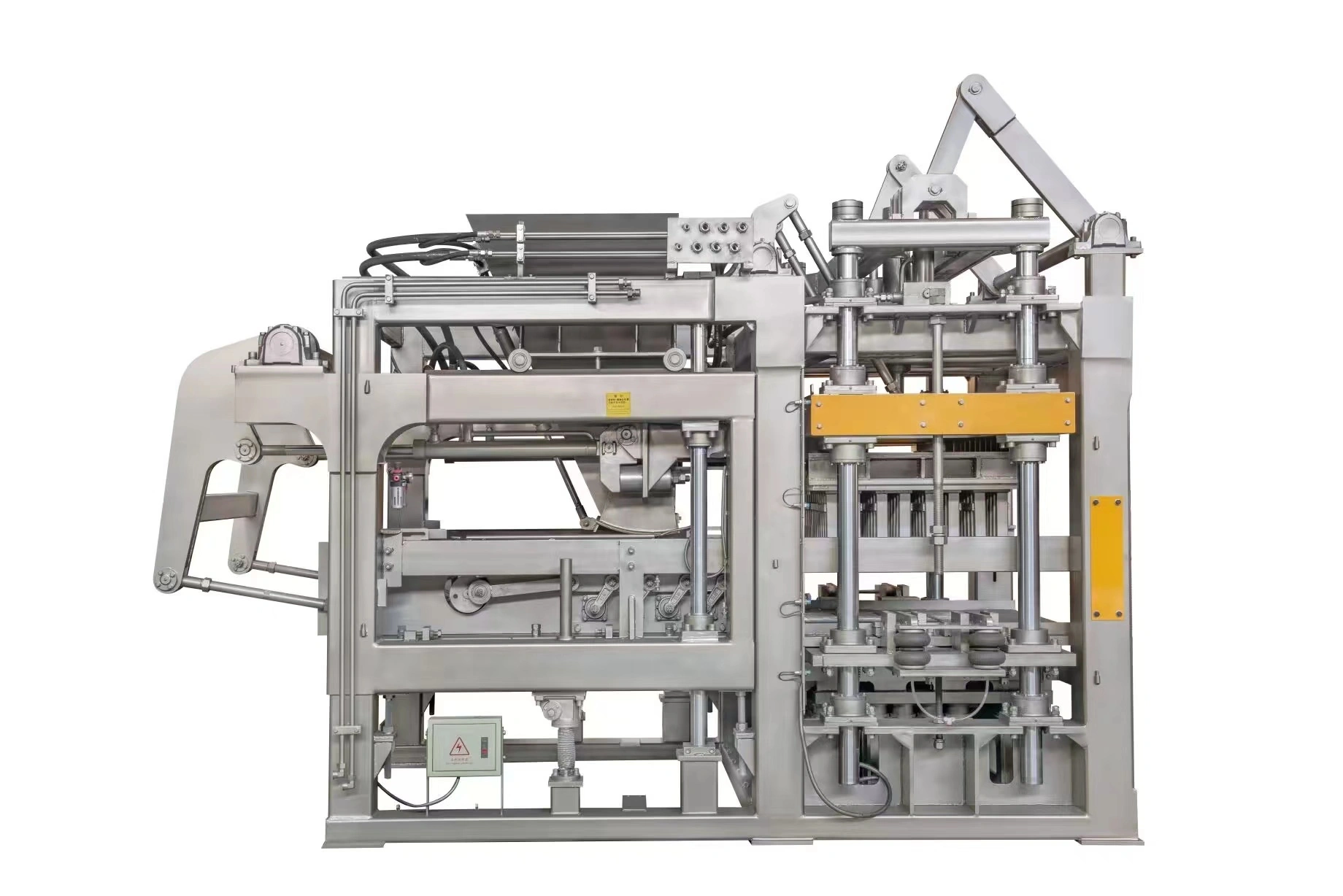

Yixin Machinery Factory Custom Heavy Duty Cement Block Making Machine Supplier QT10-15

Place of Origin: China

Minimum order quantity: 1set

Color: Silver and yellow can be customzied

Material Science: Q235 Steel ,handox steel

Packing: Film

Delivery time: 25 working days

Model: QT10-15 heavy duty

Transaction mode: TT or 100%LC

Discharge port: Xiamen port

Tech Data

|

The pressure meter on the QT10-15 heavy-duty cement block making machine from Yixin Machinery Factory plays a crucial role during operation. In a typical use scenario, it continuously monitors the pressure exerted during the block molding process. Operators rely on the pressure meter's readings to ensure the right amount of pressure is applied, guaranteeing the blocks' quality and consistency. Any deviations from the optimal pressure range can be promptly detected and adjusted, preventing defects in the final cement blocks.

The dynamic and static vibration table of the QT10-15 heavy-duty cement block making machine from Yixin Machinery Factory is designed for efficient brick production. During operation, the dynamic table vibrates vigorously while the static table remains 3 mm lower. This setup facilitates brick formation through a beating action, resulting in dense bricks. The unique design makes it well-suited for manufacturing colored bricks and high bricks, ensuring they meet quality and density standards.

In the operation of the QT10-15 heavy-duty cement block making machine from Yixin Machinery Factory, the long guide sleeves are vital components. During the block production process, they provide essential stability and balance, ensuring accurate movement of machine parts. This contributes to the consistent quality of the cement blocks. Moreover, the guiding bush can be adjusted, raised or lowered as needed. This feature helps reduce wear on the components, ultimately extending the machine's service life and lowering maintenance costs.

|

|---|

|

Product Classification Description: Yixin Machinery Factory Custom Heavy Duty Cement Block Making Machine Supplier QT10-15 Refer to : The Yixin Machinery QT10-15 is a heavy-duty cement block making machine designed for large-scale construction projects. Its robust structure and high production capacity make it ideal for manufacturing standard blocks, hollow bricks, and pavers in commercial building sites. The machine's durable components ensure continuous operation under demanding conditions, suitable for precast concrete factories and infrastructure development projects. With efficient automation and stable performance, it meets the needs of contractors and material suppliers requiring mass production of quality concrete blocks for housing, roads, and industrial facilities.

|

|---|

|

1.How many days to change vibration box oil ,what kind of oil can be used inside?

The hydraulic oil 68 degree can be used, the amount is from bottom 3cm. Strongly suggest 1 month change one time oil 2. How many hollow blocks can the Yixin Machinery QT10-15 produce per hour?

The QT10-15 can produce 1980 hollow blocks per hour, ensuring high productivity for your pavement block making needs. |

|---|

| Production Of Raw Material: | ||

|---|---|---|

| Sand, gravel, cement, can add large of slag, coal gangue, clay, ceramisite, perlite and other | ||

| Applied Products: | ||

| Production of a variety of external wall block, internal wall block, PC stone permeable brick flower wall block, floor block, dike block, chain block, curb and other blocks. | ||

| Block Size: | ||

| 240*115*53mm 390*190*190mm 240*115*90mm 150*100*100mm 190*190*90mm 200*100*60mm and other |