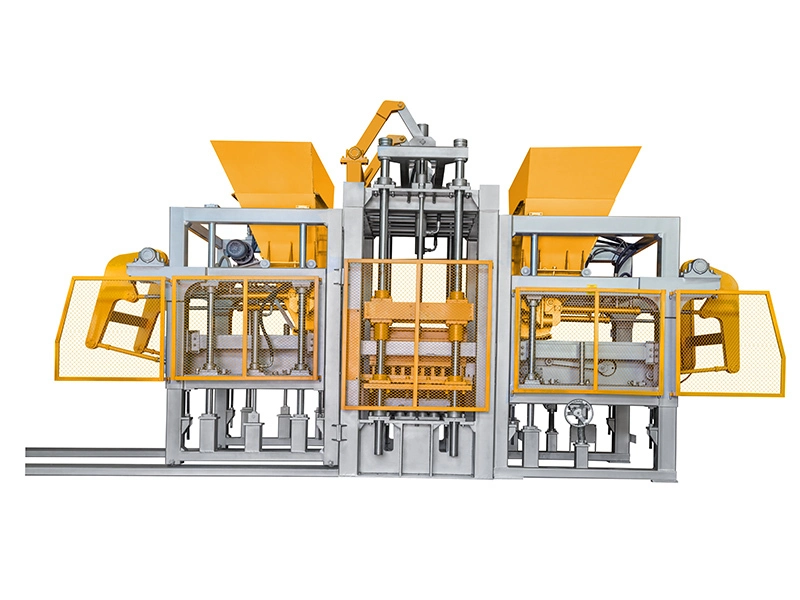

Yixin Machinery Factory Customized Fully Set Automatic Heavy Duty Clay Block Making Machine QT15-15

Place of Origin: China

Minimum order quantity: 1set

Color: Blue and yellow can be customzied

Material Science: Q235 Steel ,handox steel

Packing: Film

Delivery time: 25 working days

Model: QT15-15 Heavy Duty

Transaction mode: TT or 100%LC

Discharge port: Xiamen port

TECH DATA

|

The advance and retreat cushion pad on the Yixin QT15-15 block making machine is a critical component for ensuring smooth and stable operation. Its primary function is to provide effective buffering for the feeding car during its forward and backward movements. This mechanism significantly reduces mechanical shock and vibration generated at the start and end of each travel cycle. By absorbing these impacts, the cushion pad minimizes stress on the machine's structure and components. This results in more precise material placement, enhanced operational stability, and a notable reduction in noise. Ultimately, this feature contributes to prolonged equipment lifespan, improved brick quality, and a more reliable production process with less downtime for maintenance.

The blocks stacker for the Yixin Machinery Factory Customized Fully Set Automatic Heavy Duty Clay Block Making Machine QT15-15 is a key component designed for automated material handling. Its primary function is to systematically receive the freshly formed clay blocks from the main machine and arrange them into neat, stable stacks. This automated stacking process significantly enhances production efficiency by eliminating the need for manual labor. It ensures a consistent and orderly output, which is crucial for subsequent curing and drying stages. The stacker is engineered for heavy-duty operation, providing reliable performance that minimizes block damage and optimizes factory floor space. This results in a smoother, more continuous production line with improved overall productivity and a reduced physical workload for operators.

The flexible feeding arm on the Yixin Machinery QT15-15 automatic heavy-duty block making machine is a key component designed for enhanced operational stability. Its primary function is to systematically push the material cart during the production cycle. This automated pushing action ensures a consistent and reliable supply of raw materials to the molding area. By maintaining a steady and controlled feed, the arm minimizes material shifting and interruptions. This results in a more uniform compaction process for the heavy-duty clay blocks. The inherent flexibility of the arm allows it to accommodate minor variations, contributing to smoother overall machine operation, reduced downtime, and higher quality end products with consistent density and structural integrity.

|

|---|

|

Product Classification Description : Yixin Machinery Factory Customized Fully Set Automatic Heavy Duty Clay Block Making Machine QT15-15 Refer to : The Yixin Machinery Factory Customized Fully Set Automatic Heavy Duty Clay Block Making Machine QT15-15 is a robust and fully automated production line designed for high-volume manufacturing of clay blocks and bricks. It integrates automatic material feeding, mixing, high-pressure compression, and molding processes into a seamless operation. The system features a hydraulic drive for powerful and stable compression, ensuring the production of dense, high-strength blocks with consistent dimensions. Its programmable logic controller (PLC) allows for easy operation and customization of production parameters. This machine is engineered for efficiency, durability, and minimal manual intervention, making it an ideal solution for large-scale construction material production.

|

|---|

|

1.How long does it take to make a block with the Yixin Machinery Factory Customized Fully Set Automatic Heavy Duty Clay Block Making Machine QT15-15 ? With a cycle time of 13-25 seconds, this heavy-duty multi-function machine can produce a high volume of blocks efficiently and quickly. 2.How many solid blocks can the Yixin Machinery Factory Customized Fully Set Automatic Heavy Duty Clay Block Making Machine QT15-15 produce per hour? This high-performance machine can produce an impressive 20625 solid blocks per hour, making it a highly efficient and productive option for block making. |

|---|