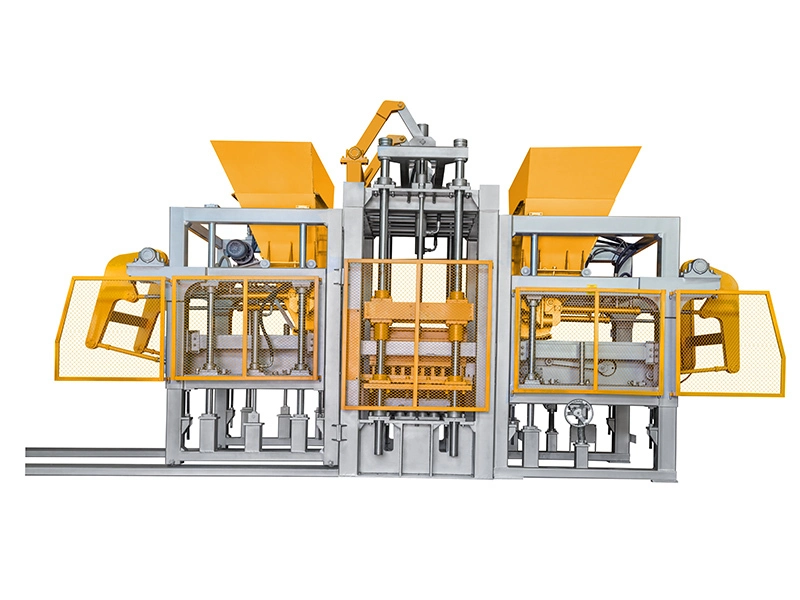

Yixin Machinery Factory Customized Fully Set Durable Quality Heavy Duty Cement Block Making Machine QT15-15

Place of Origin: China

Minimum order quantity: 1set

Color: Blue and yellow can be customzied

Material Science: Q235 Steel ,handox steel

Packing: Film

Delivery time: 25 working days

Model: QT15-15 Heavy Duty

Transaction mode: TT or 100%LC

Discharge port: Xiamen port

TECH DATA

|

The QT15-15 block making machine incorporates long guide sleeves that are fundamental to its robust performance. These components provide exceptional stability and balance to the entire system during operation. A key feature is the guiding bush's ability to be raised and lowered. This specific function is engineered to distribute wear more evenly across the components. Consequently, this intelligent design significantly reduces friction and material degradation, leading to a substantial extension of the machine's overall service life and reduced maintenance needs.

The advance and retreat cushion pads in the QT15-15 block making machine are key components for ensuring smooth operation. They provide effective buffering for the feeding car during its forward and backward movements. This system significantly reduces impact and vibration, leading to enhanced stability and precision in the concrete block production process. By minimizing mechanical stress, these pads help protect the machine's structure, contributing to greater durability and a longer operational lifespan for the equipment.

The dynamic and static vibration table on the QT15-15 block making machine ensures superior performance. It utilizes a flexible coupling for smooth power transmission and even force distribution. This dual-system effectively eliminates internal bubbles in the concrete mixture. The result is consistently high-density, perfectly compacted blocks with excellent surface finish and structural integrity, significantly enhancing the final product quality.

|

|---|

|

Product Classification Description : Yixin Machinery Factory Customized Fully Set Durable Quality Heavy Duty Cement Block Making Machine QT15-15 Refer to : The Yixin QT15-15 is a heavy-duty, fully automatic cement block making machine designed for high-volume production. It features a robust structure for exceptional durability and stable operation. This model efficiently produces various cement blocks, pavers, and bricks with consistent quality and high density. The automated system ensures precise control over the entire process, from mixing and feeding to molding and palletizing. Customizable to meet specific production needs, it is an ideal solution for large-scale construction projects and industrial block manufacturing, offering both reliability and superior performance.

|

|---|

|

1.How long does it take to make a block with the Yixin Machinery Factory Customized Fully Set Durable Quality Heavy Duty Cement Block Making Machine QT15-15 ? With a cycle time of 13-25 seconds, this heavy-duty multi-function machine can produce a high volume of blocks efficiently and quickly. 2.How many solid blocks can the Yixin Machinery Factory Customized Fully Set Durable Quality Heavy Duty Cement Block Making Machine QT15-15 produce per hour? This high-performance machine can produce an impressive 20625 solid blocks per hour, making it a highly efficient and productive option for block making. |

|---|

|

1.Adopting the best international design process, advanced technology. 2.Crank arm fabrication, fast and uniform. 3.Guide column dynamic demoulding mechanism, demoulding parallel and more accurate. 4.Suspended material cart, fabrication faster and more durable. 5.The vibration box adopts a variety of linkage vibrations, with a large molding area and high product density. 6.Servo frequency modulation drive control can be selected, with fast vibration start, short molding cycle and more accurate control. 7.Optional intelligent remote control electronic control can grasp the equipment operation status in real time, remotely control, operate, judge and solve equipment failures; online monitoring of the equipment operation status, online prediction and diagnosis of the equipment application operation and status. |

|---|