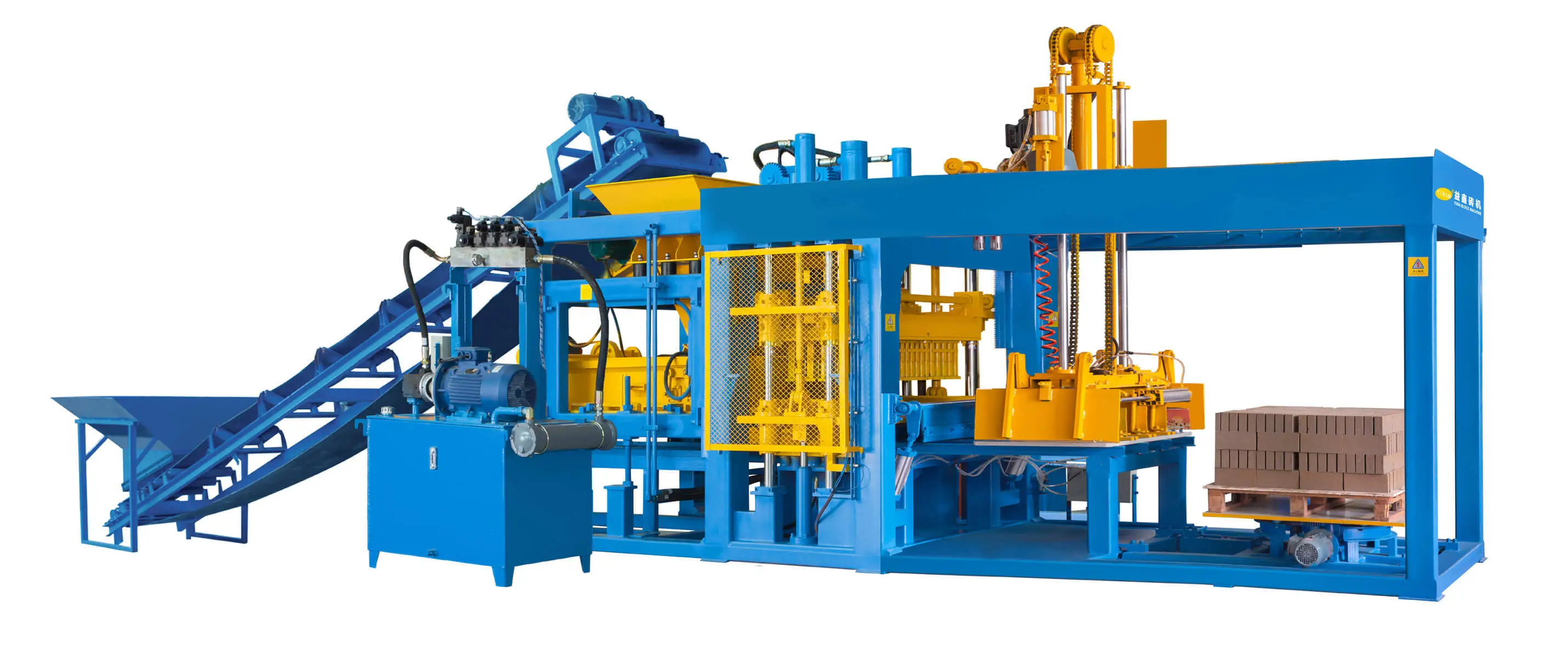

Yixin Machinery Factory Hot Sale Fully Set High Standard Free Pallet Fly Ash Block Making Machine QTMT12-15

Place of Origin: China

Minimum order quantity: 1set

Color: Blue and yellow can be customzied

Material Science: Q235 Steel ,handox steel

Packing: Film

Delivery time: 25 working days

Model: QTMT 12-15

Transaction mode: TT or 100%LC

Discharge port: Xiamen port

TECH DATA

|

The autognostic and guiding functions integrated into the Yixin QTMT12-15 block making machine are pivotal for ensuring uninterrupted, high-volume production. In a busy factory setting, where the machine operates continuously to produce fly ash blocks, these intelligent systems constantly monitor the hydraulic pressure, vibration motors, and control circuitry. Should an irregularity occur, such as a misaligned pallet or a sensor failure, the system immediately halts operations to prevent substandard products or mechanical damage.

The Yixin QTMT12-15 Fully Set Fly Ash Block Making Machine integrates advanced German hydraulic technology to deliver superior performance. Its multi-hydraulic driving system is a core feature, generating exceptionally powerful vibrations. This intense vibration ensures the raw materials are compacted more thoroughly and efficiently. As a direct result, the machine achieves a significantly shorter forming cycle, boosting production output. Furthermore, this high-pressure compaction process greatly enhances the final product's density and strength, producing highly durable bricks and blocks. This combination of power, speed, and quality makes it an ideal solution for high-volume production of premium construction materials.

The QTMT12-15 block making machine from Yixin Machinery incorporates a Hanging Type Two-way Positioning Material Holder, a key feature that significantly enhances production stability and product quality. This innovative system experiences minimal resistance during operation, ensuring smooth and efficient material handling. Its primary function is to automatically compensate for inconsistencies in the thickness of the bottom pallet board. By precisely positioning the mold and materials regardless of pallet variations, it effectively eliminates the negative impact of such dimensional errors. This results in the consistent production of high-precision fly ash blocks with uniform dimensions, superior surface finish, and enhanced structural integrity, thereby reducing waste and improving overall output quality. |

|---|

| Product Classification Description :Yixin Machinery Factory Hot Sale Fully Set High Standard Free Pallet Fly Ash Block Making Machine QTMT12-15

Refer to :The Yixin QTMT12-15 is a high-capacity, fully automatic block making machine designed for producing premium fly ash blocks. It operates on a semi-dry concrete process and features an automatic pallet feeding system for uninterrupted production. With 12 mold stations and a 15-second molding cycle, it delivers high output efficiency. The machine incorporates a strong vibration system and pressure control to ensure products have high density, precise dimensions, and excellent strength. Its PLC control system allows for easy operation and adjustment of block specifications. This robust system is ideal for large-scale industrial production of standard blocks, interlocking pavers, and other cement-based products.

|

|---|

|

1.What is the host machine power of Yixin Machinery Factory Hot Sale Fully Set High Standard Free Pallet Fly Ash Block Making Machine QTMT12-15 ?

The host machine power is 58 (KW), ensuring thorough and efficient compaction for high-quality clay block production.

2.How many hollow blocks can Yixin Machinery Factory Hot Sale Fully Set High Standard Free Pallet Fly Ash Block Making Machine QTMT12-15 produce in a class?

The machine can output 46080-61440 hollow blocks in just 8 hours, making it a highly efficient and productive choice for clay block manufacturing.

3.How many days to change vibration box oil ,what kind of oil can be used inside?

The hydraulic oil 68 degree can be used, the amount is from bottom 3cm. Strongly suggest 1 month change one time oil.

|

|---|

|

|

|---|