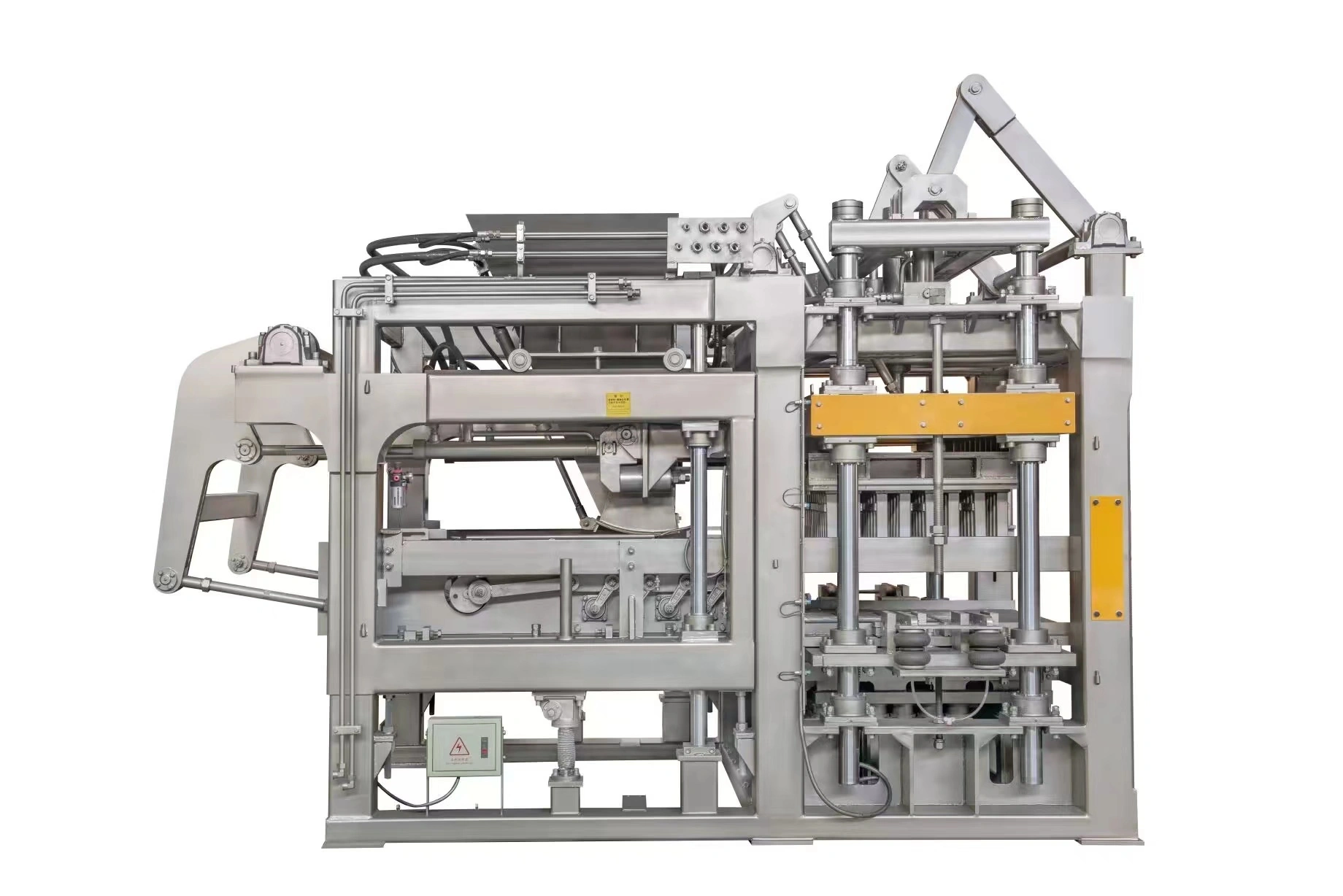

Yixin Machinery Factory Hot Sale High Accuracy Durable Heavy Duty Interlocking Block Forming Machine QT10-15

Place of Origin: China

Minimum order quantity: 1set

Color: Blue and yellow can be customzied

Material Science: Q235 Steel ,handox steel

Packing: Film

Delivery time: 25 working days

Model: QT10-15 heavy duty

Transaction mode: TT or 100%LC

Discharge port: Xiamen port

Tech Data

|

The QT10-15 interlocking block forming machine from Yixin Machinery Factory is equipped with high-performance wear-resistant copper sleeves for enhanced durability and operational smoothness. These specially designed sleeves serve as bushings for the guide pillars, significantly reducing friction and wear during the high-frequency vibration and pressing processes. Their superior material quality ensures a long service life without scoring or damaging the critical guide pillars. This maintenance-friendly feature minimizes downtime and ensures consistent production of high-accuracy blocks, making the machine a reliable and cost-effective solution for heavy-duty industrial applications.

The automatic pallet feeding system integrated into the Yixin QT10-15 block forming machine is engineered for large-scale, high-output production environments. It is ideally deployed in industrial brick and block manufacturing plants, major construction projects requiring a continuous on-site supply of pavers and hollow blocks, and precast concrete product factories. This system eliminates manual pallet handling, ensuring a seamless, uninterrupted production flow. It significantly boosts output by synchronizing perfectly with the machine’s rapid cycle time, while also enhancing operational safety and reducing labor costs. This automation is crucial for producers aiming for maximum efficiency, consistent product quality, and a swift return on investment from their equipment.

The advance and retreat cushion pad is a critical component of the QT10-15 block forming machine. Its primary function is to provide effective buffering and significantly reduce vibration for the feeding car during its operational cycle. This damping action ensures a smoother and more controlled forward and backward movement, which enhances the stability of the entire brick molding process. By absorbing shock and minimizing mechanical oscillations, the pad not only protects the machine's structure from excessive wear and tear but also contributes to higher product consistency and a longer service life for the equipment.

|

|---|

|

Product Classification Description: Yixin Machinery Factory Hot Sale High Accuracy Durable Heavy Duty Interlocking Block Forming Machine QT10-15 Refer to :The QT10-15 Interlocking Block Forming Machine from Yixin Machinery Factory is a robust, high-capacity solution for producing a wide variety of concrete blocks and pavers. Renowned for its durability and heavy-duty construction, it ensures reliable operation under demanding conditions. The machine excels in producing high-accuracy interlocking blocks with consistent dimensions and a superior finish. Its fully automatic system features an advanced electronic control for precise operation and minimal manual intervention. With a notable output of up to 10,320 standard blocks per eight-hour shift, it maximizes productivity.

|

|---|

|

1.How many days to change vibration box oil ,what kind of oil can be used inside?

The hydraulic oil 68 degree can be used, the amount is from bottom 3cm. Strongly suggest 1 month change one time oil 2. How many hollow blocks can the Yixin Machinery QT10-15 produce per hour?

The QT10-15 can produce 1980 hollow blocks per hour, ensuring high productivity for your pavement block making needs. |

|---|

|

|

|---|