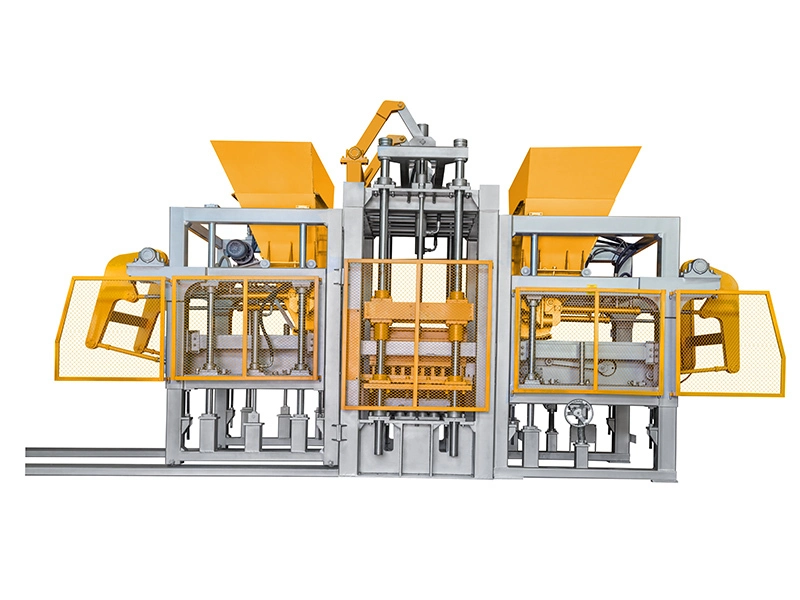

Yixin Machinery Factory Wholesale Robust Quality Automatic Heavy Duty Interlocking Block Making Machine QT12-15

Place of Origin: China

Minimum order quantity: 1set

Color: Silver and yellow can be customzied

Material Science: Q235 Steel ,handox steel

Packing: Film

Delivery time: 25 working days

Model: QT12-15 heavy duty

Transaction mode: TT or 100%LC

Discharge port: Xiamen port

Tech Data

|

The QT12-15 automatic heavy-duty interlocking block making machine from Yixin Machinery Factory is engineered for large-scale, high-volume production in the construction industry. Its primary application is in manufacturing a wide range of concrete products, including standard solid/hollow blocks, interlocking pavers, and curb stones. This machine is perfectly suited for established brick-making plants and major construction projects that require a continuous and reliable supply of high-quality building materials. The fully automatic system ensures consistent output with minimal manual intervention, significantly boosting efficiency.

The dynamic and static vibration table integrated into the Yixin QT12-15 block making machine is engineered for high-performance production scenarios. Its primary application is in the manufacturing of high-density, precision concrete blocks, pavers, and bricks. The dual vibration system ensures a thorough and uniform compaction of the raw concrete mixture within the mold. This process effectively removes air pockets, resulting in products with superior structural integrity, excellent surface finish, and consistent dimensional accuracy. It is ideally suited for large-scale wholesale operations and heavy-duty industrial projects that demand reliable output of robust, interlocking building materials. The efficiency of this table is crucial for achieving optimal production rates and maintaining the machine's renowned reputation for quality and durability.

The raw material hopper of the Yixin QT12-15 block making machine is designed for high-volume production environments. It operates in large-scale construction material plants and industrial yards, where a continuous supply of raw materials like concrete, sand, and gravel is essential. The hopper efficiently receives bulk materials from automated batching systems or conveyor belts, ensuring a non-stop workflow. Its robust construction handles the heavy, abrasive nature of the mix, facilitating smooth and consistent feeding into the molding system. This design is critical for maintaining the machine's high output of interlocking blocks, paving stones, and other cement-based products, making it a cornerstone for efficient, unattended operation in demanding 24/7 manufacturing cycles.

|

|---|

|

Product Classification Description:Yixin Machinery Factory Wholesale Robust Quality Automatic Heavy Duty Interlocking Block Making Machine QT12-15 Refer to : The QT12-15 from Yixin Machinery Factory is an exemplary automatic block making machine, engineered for high-volume production. Its fully automated operation ensures consistent output with minimal manual labor, significantly boosting efficiency. The machine is renowned for producing robust, heavy-duty interlocking blocks with superior compressive strength and precise dimensions, ideal for major construction projects. Durability is a key advantage, as it is constructed with high-quality components for long-term reliability in demanding environments. Furthermore, its energy-efficient design helps in reducing operational costs. The QT12-15 is not only user-friendly but also highly versatile, capable of manufacturing various block types by simply changing molds.

|

|---|

|

1.How many days to change vibration box oil ,what kind of oil can be used inside?

The hydraulic oil 68 degree can be used, the amount is from bottom 3cm. Strongly suggest 1 month change one time oil 2. How many hollow blocks can the Yixin Machinery QT12-15 produce per hour?

The QT12-15 can produce 2376 hollow blocks per hour, ensuring high productivity for your pavement block making needs. |

|---|

|

|

|---|