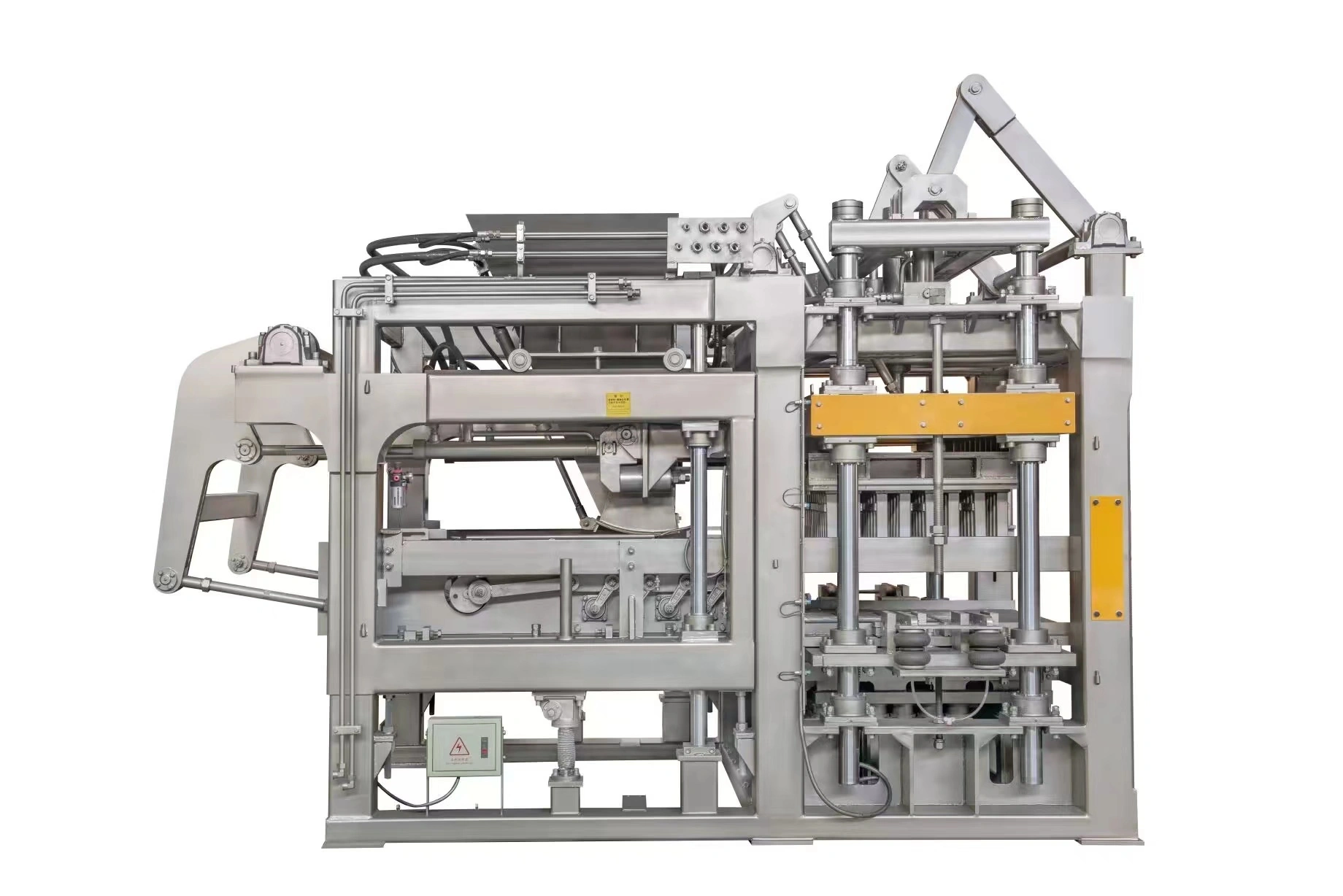

Yixin Machinery Fast Delivery Premium Quality Durable Heavy Duty Clay Block Forming Machine QT10-15

Place of Origin: China

Minimum order quantity: 1set

Color: Blue and yellow can be customzied

Material Science: Q235 Steel ,handox steel

Packing: Film

Delivery time: 25 working days

Model: QT10-15 heavy duty

Transaction mode: TT or 100%LC

Discharge port: Xiamen port

Tech Data

|

The stirring teeth of the Yixin QT10-15 block forming machine are engineered for exceptional performance and longevity. Manufactured from high-strength, wear-resistant alloy steel, they possess superior durability to withstand the abrasive nature of clay and concrete mixtures. Their unique spiral design ensures a thorough and homogeneous mixing action, effectively eliminating dead zones and preventing material segregation. This efficient blending guarantees a consistent, high-density feed for the molding system, which is crucial for producing uniform, premium-quality blocks. The robust construction significantly reduces the frequency of replacement, minimizing downtime and maintenance costs. This reliability directly contributes to the machine's overall productivity, making it a key component for continuous, heavy-duty operation.

The dynamic and static vibration system of the Yixin QT10-15 block forming machine is engineered for superior performance. The static vibration ensures initial compaction for a smooth block surface and precise dimensional accuracy. The dynamic vibration provides high-frequency, forceful compaction, effectively removing air pockets to achieve optimal density and exceptional structural strength for the final blocks. This dual-system approach guarantees a uniform material distribution, resulting in products with consistent quality and a professional finish. It enhances production efficiency by facilitating faster mold cycles without compromising the integrity of the blocks, making it ideal for manufacturing high-load-bearing bricks and durable pavers. The system's robust design ensures reliable, long-term operation.

The servo hydraulic system of the Yixin QT10-15 block forming machine is engineered for high-volume production environments where precision, efficiency, and reliability are critical. It is ideally deployed in large-scale construction material plants and industrial brick-making facilities that manufacture standard and specialty clay blocks for commercial and residential projects. The system excels in continuous, 24/7 operation, ensuring consistent product quality with minimal energy consumption. Its precise control allows for quick mold changes and adjustments, making it perfect for producing various block types and sizes on demand. This machine is a cornerstone for businesses focused on meeting tight project deadlines without compromising on the durability and structural integrity of their building materials.

|

|---|

|

Product Classification Description: Yixin Machinery Fast Delivery Premium Quality Durable Heavy Duty Clay Block Forming Machine QT10-15 Refer to :The QT10-15 from Yixin Machinery is an industrial-grade block forming machine engineered for high-volume production environments. Its primary application is in the manufacturing of solid, hollow, and interlocking clay bricks for large-scale construction projects. This durable machine is ideal for established brick-making plants and construction companies requiring a consistent, high-output supply of premium quality blocks. The heavy-duty design ensures reliable, continuous operation, making it suitable for fulfilling major contracts for housing developments, commercial complexes, and infrastructure like paving and landscaping. The fast delivery capability of the equipment itself allows businesses to quickly ramp up production capacity to meet tight project deadlines without compromising on the structural integrity of the final clay products.

|

|---|

|

1.How many days to change vibration box oil ,what kind of oil can be used inside?

The hydraulic oil 68 degree can be used, the amount is from bottom 3cm. Strongly suggest 1 month change one time oil 2. How many hollow blocks can the Yixin Machinery QT10-15 produce per hour?

The QT10-15 can produce 1980 hollow blocks per hour, ensuring high productivity for your pavement block making needs. |

|---|

|

1.Adopting the best international design process, advanced technology. 2.Crank arm fabrication, fast and uniform. 3.Guide column dynamic demoulding mechanism, demoulding parallel and more accurate. 4.Suspended material cart, fabrication faster and more durable. 5.The vibration box adopts a variety of linkage vibrations, with a large molding area and high product density. 6.Servo frequency modulation drive control can be selected, with fast vibration start, short molding cycle and more accurate control. 7.Optional intelligent remote control electronic control can grasp the equipment operation status in real time, remotely control, operate, judge and solve equipment failures; online monitoring of the equipment operation status, online prediction and diagnosis of the equipment application operation and status. |

|---|