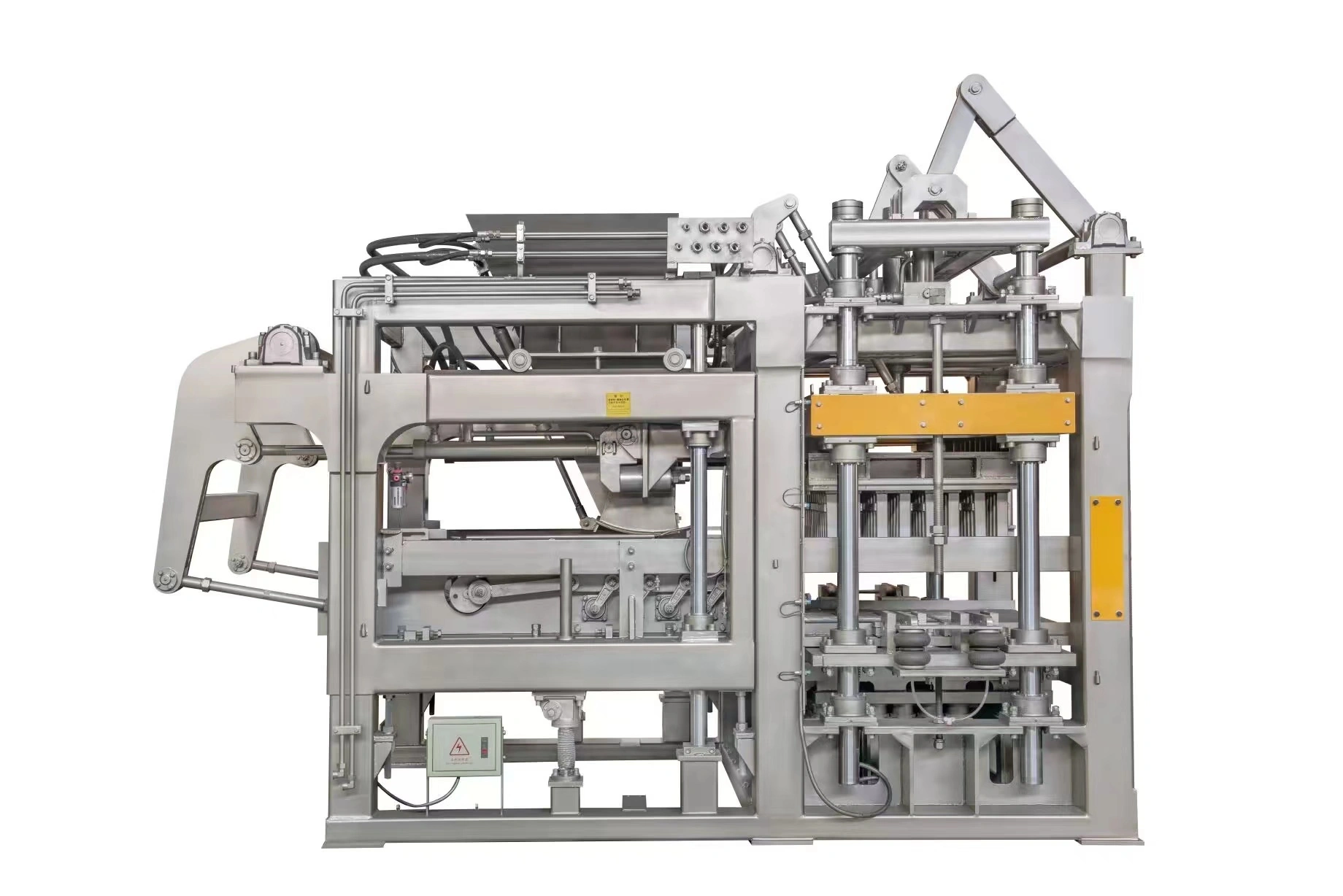

Yixin Machinery Fast Shipping Multifunctional Hydraulic Heavy Duty Customized Cement Block Making Machine QT6-15

Place of Origin: China

Minimum order quantity: 1set

Color: Silver and yellow can be customzied

Material Science: Q235 Steel ,handox steel

Packing: Film

Delivery time: 25 working days

Model: QT6-15 heavy duty

Transaction mode: TT or 100%LC

Discharge port: Xiamen port

Tech Data

| ITEM | QT6-15HD |

|---|---|

| VIBRATION FREQUENCY | 3800-4500(T/S) |

| CYCLE TIME |

15-25(S) |

| VIBRATION FORCE | 95(KN) |

| VATED PRESSURE | 21(MPA) |

| POWER | 34.54(KW) |

| VIBRATION TYPE |

VIBRATION& PRESS |

|

.The stirring teeth of the Yixin Machinery QT6-15 block making machine are a critical component within the mixing system. Their primary function is to ensure the thorough and homogeneous blending of raw materials, such as cement, sand, aggregate, and water. Designed for durability, these teeth aggressively break down material clumps and prevent segregation during the mixing cycle. This efficient mixing action guarantees a consistent concrete mixture with uniform texture and optimal moisture content. The result is a high-quality mix that directly contributes to the production of dense, strong, and precisely formed cement blocks with excellent surface finish, while also enhancing the overall efficiency and reliability of the QT6-15 machine.

The PLC control unit serves as the intelligent core of the Yixin Machinery QT6-15 block making machine. It precisely manages the entire production cycle, from raw material feeding and mixing to molding, compaction, and demolding. This centralized system automates all equipment actions, ensuring synchronized and efficient operation. It allows for customizable programs to produce different block types and specifications. The unit enhances reliability, provides real-time monitoring, and simplifies operation through a user-friendly interface, guaranteeing consistent, high-quality output with minimal manual intervention.

The flexible feeding arm on the Yixin QT6-15 block making machine is a key component designed to automate and stabilize the material handling process. Its primary function is to systematically push the material cart that supplies concrete mix to the mold area. This automated pushing action ensures a consistent and measured feed of material, which is crucial for maintaining uniform block density and quality. By replacing manual or less controlled methods, the arm enhances overall operational stability, reduces material spillage, and contributes to a smoother, more efficient production cycle for high-volume cement block manufacturing.

|

|---|

|

Product Classification Description: Yixin Machinery Fast Shipping Multifunctional Hydraulic Heavy Duty Customized Cement Block Making Machine QT6-15 Refer to: The Yixin Machinery QT6-15 is a robust, multifunctional hydraulic block making machine designed for high-volume production. Its primary use is in the manufacturing of various cement concrete blocks, including solid, hollow, and interlocking pavers. Ideal for large-scale construction projects, precast plants, and commercial block yards, it efficiently produces standard blocks, curbstones, and landscaping products. The machine's heavy-duty design and customization options allow it to adapt to specific material mixes and product dimensions. With fast shipping and streamlined operation, it enables continuous, high-output production to meet tight deadlines for infrastructure development, housing complexes, and industrial flooring, ensuring consistent quality and durability in the final products.

|

|---|

| 1.What is the vibration frequency for Yixin Machinery Fast Shipping Multifunctional Hydraulic Heavy Duty Customized Cement Block Making Machine QT6-15 ? The vibration frequency is 3800-4500(T/S) , making it highly efficient for producing curbstone and interlocking blocks. Efficient and fast production for all your construction needs.

2.How many liter hydraulic oil used?

68 degree hydraulic oil 600L request. 3.What is the estimated date of shipment for Yixin Machinery Fast Shipping Multifunctional Hydraulic Heavy Duty Customized Cement Block Making Machine QT6-15 after mold confirmation?

|

|---|

| Production Of Raw Material: | ||

|---|---|---|

| Sand, gravel, cement, can add large of slag, coal gangue, clay, ceramisite, perlite and other | ||

| Applied Products: | ||

| Production of a variety of external wall block, internal wall block, PC stone permeable brick flower wall block, floor block, dike block, chain block, curb and other blocks. | ||

| Block Size: | ||

| 240*115*53mm 390*190*190mm 240*115*90mm 150*100*100mm 190*190*90mm 200*100*60mm and other |