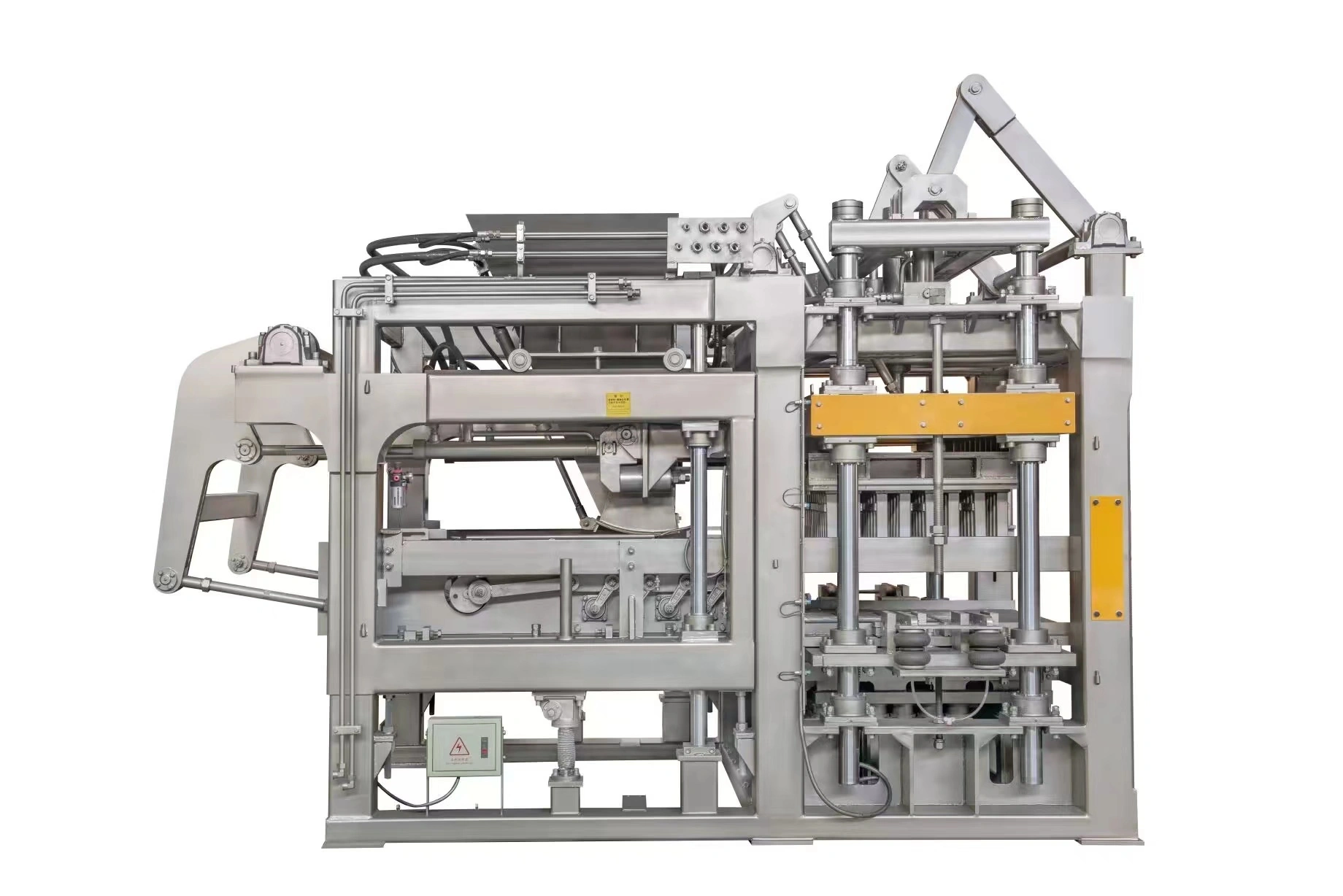

Yixin Machinery Global Hot Sale High Standard Quality Certification Automatic Heavy Duty Compressed Block Machine QT10-15

Place of Origin: China

Minimum order quantity: 1set

Color: Blue and yellow can be customzied

Material Science: Q235 Steel ,handox steel

Packing: Film

Delivery time: 25 working days

Model: QT10-15 heavy duty

Transaction mode: TT or 100%LC

Discharge port: Xiamen port

Tech Data

|

The wear-resistant strips on the Yixin QT10-15 block making machine are designed for operational efficiency in high-volume production environments. In busy construction material plants or block yards, where the machine runs continuously to produce concrete blocks, these components experience significant friction. The key advantage is their independent design, which allows for quick replacement during routine maintenance pauses without dismantling major sections. This minimizes machine downtime compared to models with integral cast steel parts. For operators and maintenance technicians, this translates to faster service, reduced labor costs, and sustained production output. Ultimately, this feature ensures the machine maintains consistent performance and longevity with minimal disruption to daily operations.

The advance and retreat cushion pads on the Yixin QT10-15 block machine are critical for smooth operation in high-volume production environments. These pads provide essential buffering during the feeding car's movement cycle. As the car advances to deposit raw materials into the mold and then retracts, the cushions absorb kinetic energy, significantly reducing mechanical shock and vibration. This not only protects the machine's structure from stress and wear but also ensures precise material placement for consistent block quality. The reduction in vibration minimizes noise pollution in the plant and contributes to a safer, more stable working platform for the entire machine system, enhancing overall durability and operational efficiency during continuous, heavy-duty use.

The extended long guide sleeves in the Yixin QT10-15 block-making machine are essential for demanding, continuous production environments. In large-scale construction projects or high-output brick manufacturing plants, this feature ensures exceptional stability during the high-frequency vibration and heavy compaction of raw materials. By providing precise vertical guidance to the mold head, it guarantees perfectly aligned and dimensionally consistent blocks every cycle. Furthermore, the innovative design allows the guiding bush to be periodically raised or lowered. This adjustability distributes wear evenly across its surface, significantly reducing maintenance downtime and extending the machine's operational lifespan in rugged, 24/7 industrial applications. It is a critical feature for maximizing productivity and product quality.

|

|---|

|

Product Classification Description: Yixin Machinery Global Hot Sale High Standard Quality Certification Automatic Heavy Duty Compressed Block Machine QT10-15 Refer to :The Yixin Machinery QT10-15 Block Machine is engineered for large-scale, high-volume production in the construction industry. Its primary application is in stationary plants that manufacture a wide range of concrete products, including standard blocks, hollow blocks, paving stones, and interlocking bricks for landscaping. The fully automatic operation ensures consistent output and minimal manual intervention, making it ideal for supplying major building projects, infrastructure development, and commercial housing complexes. Its heavy-duty design and quality certifications guarantee reliability for continuous operation, meeting the demands of both domestic and international markets where durable, precision-made construction materials are required.

|

|---|

|

1.How many days to change vibration box oil ,what kind of oil can be used inside?

The hydraulic oil 68 degree can be used, the amount is from bottom 3cm. Strongly suggest 1 month change one time oil 2. How many hollow blocks can the Yixin Machinery QT10-15 produce per hour?

The QT10-15 can produce 1980 hollow blocks per hour, ensuring high productivity for your pavement block making needs. |

|---|

| Production Of Raw Material: | ||

|---|---|---|

| Sand, gravel, cement, can add large of slag, coal gangue, clay, ceramisite, perlite and other | ||

| Applied Products: | ||

| Production of a variety of external wall block, internal wall block, PC stone permeable brick flower wall block, floor block, dike block, chain block, curb and other blocks. | ||

| Block Size: | ||

| 240*115*53mm 390*190*190mm 240*115*90mm 150*100*100mm 190*190*90mm 200*100*60mm and other |