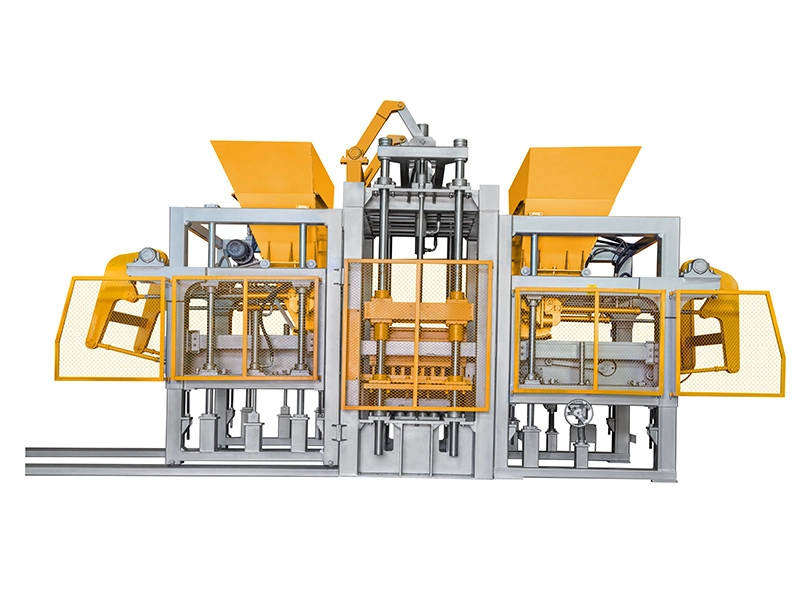

Yixin Machinery Heavy Duty Quality Wholesale Products Clay Block Making Machine QT18-15

Material Science: Q235 Steel ,handox steel

Packing: Film

Delivery time: 10 working days

Model: QT18-15 Heavy Duty

Transaction mode: TT or 100%LC

Discharge port: Xiamen port

TECH DATA

|

The Yixin Machinery QT18-15 Clay Block Making Machine utilizes a 90-diameter guide cylinder and 400-height bushing, ensuring stable and synchronized movement of the tamper head and mould frame. This design enhances precision, reduces vibration, and maintains consistent block quality, making it ideal for high-efficiency, durable clay block production.

The advance and retreat cushion pad in the Yixin Machinery QT18-15 Clay Block Making Machine provides effective buffering, reducing vibration during the feeding car's movement. This ensures smoother operation, minimizes wear and tear, and enhances the machine's durability. The feature improves material feeding precision, resulting in consistent, high-quality clay block production.

The automatic pallet provider in the Yixin Machinery QT18-15 Clay Block Making Machine ensures seamless and efficient block handling. It enhances production continuity by automatically supplying and removing pallets, reducing manual labor and downtime. This feature improves operational efficiency, ensures consistent block quality, and supports high-volume, uninterrupted clay block manufacturing.

|

|---|

|

Product Classification Description : Yixin Machinery Heavy Duty Quality Wholesale Products Clay Block Making Machine QT18-15 Refer to : The Yixin Machinery Heavy Duty Clay Block Making Machine QT18-15 excels with its robust quality, designed for wholesale production needs. Its highlights include high efficiency, ensuring rapid output of clay blocks. The machine boasts precision engineering, delivering consistent block quality. Its heavy-duty construction guarantees longevity and reliability, withstanding continuous use.

|

|---|

| |

|---|

|

1.Adopting the best international design process, advanced technology. 2.Crank arm fabrication, fast and uniform. 3.Guide column dynamic demoulding mechanism, demoulding parallel and more accurate. 4.Suspended material cart, fabrication faster and more durable. 5.The vibration box adopts a variety of linkage vibrations, with a large molding area and high product density. 6.Servo frequency modulation drive control can be selected, with fast vibration start, short molding cycle and more accurate control. 7.Optional intelligent remote control electronic control can grasp the equipment operation status in real time, remotely control, operate, judge and solve equipment failures; online monitoring of the equipment operation status, online prediction and diagnosis of the equipment application operation and status. |

|---|