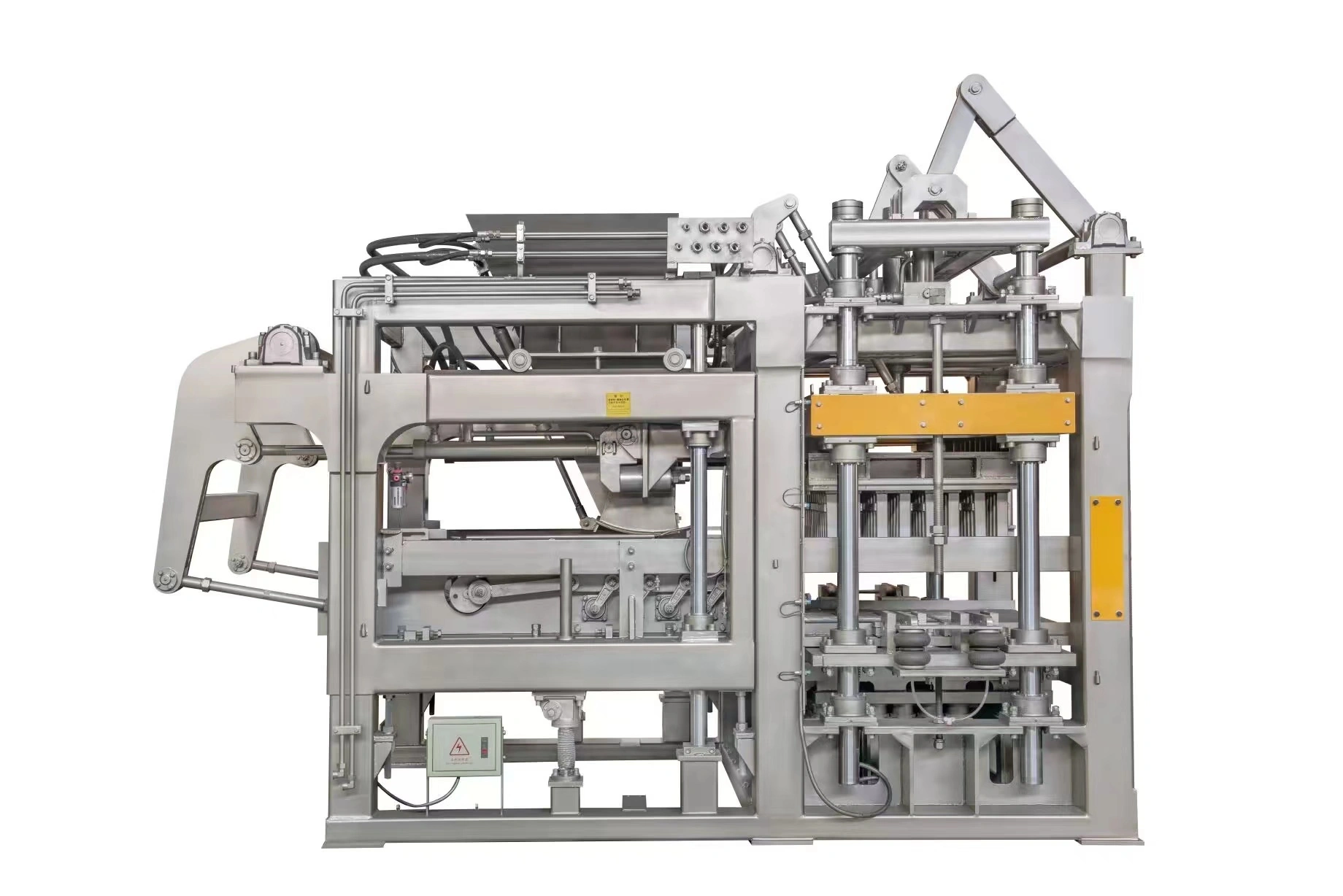

Yixin Machinery Heavy Duty Robust Hydraulic Curb Block Manufacturing Machine QT10-15

Place of Origin: China

Minimum order quantity: 1set

Color: Silver and yellow can be customzied

Material Science: Q235 Steel ,handox steel

Packing: Film

Delivery time: 25 working days

Model: QT10-15 heavy duty

Transaction mode: TT or 100%LC

Discharge port: Xiamen port

TECH DATA

|

The flexible feeding arm in the Yixin Machinery QT10-15 enhances stability by efficiently pushing the material cart during operation. This feature ensures smooth and consistent material flow, reducing block defects and improving production quality. Its robust design minimizes downtime, increases operational efficiency, and supports seamless integration into the manufacturing process.

The automatic pallet provider in the Yixin Machinery QT10-15 enhances production efficiency by seamlessly delivering pallets for block molding. It ensures smooth operation, reduces manual labor, and minimizes downtime. This feature improves workflow consistency, supports high-volume output, and maintains precision in block manufacturing,

The Yixin Machinery QT10-15 features a durable bar in the vibration table, a cast vibration box, and a synchronized vibration shaft, ensuring robust and consistent mould forming. These components enhance vibration efficiency, improve block density, and deliver superior strength and durability. The design ensures stable performance, reduces maintenance, and supports high-quality curb block production with excellent structural integrity.

|

|---|

|

Product Classification Description:Yixin Machinery Heavy Duty Robust Hydraulic Curb Block Manufacturing Machine QT10-15 Refer to : The Yixin Machinery QT10-15 Heavy Duty Robust Hydraulic Curb Block Manufacturing Machine excels in durability and efficiency. Its advanced hydraulic system ensures high-pressure compaction, producing dense, strong blocks. The synchronized vibration mechanism, durable vibration table, and cast vibration box enhance uniformity and strength.

|

|---|

|

1.Can this machine make my bricks or bricks of other sizes? We will design and make mold according to customer's drawing. 2.What is the vibration frequency of this machine? 3800-4500(r/min)

|

|---|