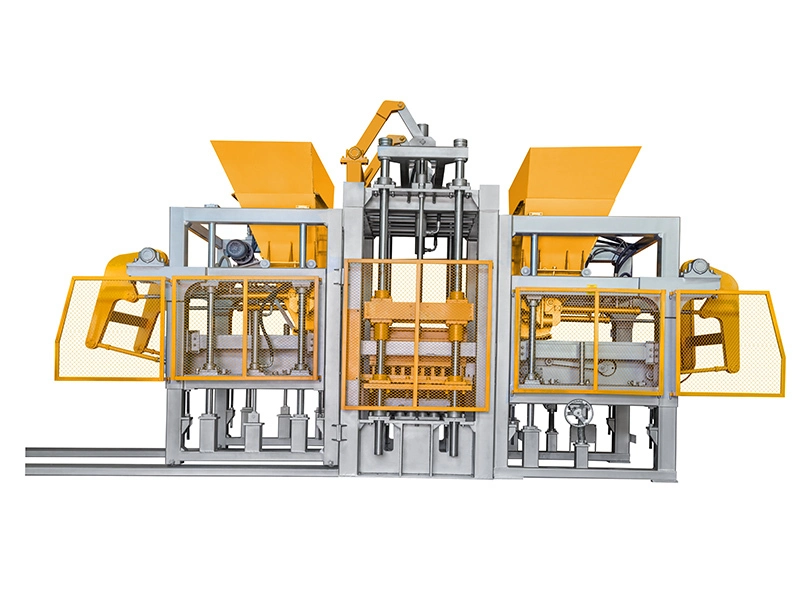

Yixin Machinery High Quality Heavy Duty Full Set Paver Block Making Machine QT18-15 features a reliable air bag system for precise and efficient operation, ensuring high quality products and maximizing productivity.

Yixin Machinery High Quality Heavy Duty Full Set Paver Block Making Machine QT18-15

Place of Origin: China

Minimum order quantity: 1set

Color: Silver and yellow can be customzied

Material Science: Q235 Steel ,handox steel

Packing: Film

Delivery time: 25 working days

Model: QT18-15 heavy duty

Transaction mode: TT or 100%LC

Discharge port: Xiamen port

TECH DATA

|

The Yixin Machinery High Quality Heavy Duty Full Set Paver Block Making Machine QT18-15 utilizes a 90 diameter guide cylinder and 400 height bushing for stable synchronization of tamper head and mould frame movement. Get precise and consistent results every time.

The PLC control unit ensures seamless coordination of all equipment actions and processes in Yixin Machinery's high-quality QT18-15 paver block making machine. Experience unrivaled precision and efficiency with this advanced system.

|

|---|

|

Product Classification Description: Yixin Machinery High Quality Heavy Duty Full Set Paver Block Making Machine QT18-15 Refer to: classification description: Yixin Machinery's QT18-15 Paver Block Making Machine uses Germany brand Continental airbag with pressure control system, making it easy for operators to change and fix molds. This ensures precise and efficient block production.

|

|---|

|

|

|---|

|

1.Adopting the best international design process, advanced technology. 2.Crank arm fabrication, fast and uniform. 3.Guide column dynamic demoulding mechanism, demoulding parallel and more accurate. 4.Suspended material cart, fabrication faster and more durable. 5.The vibration box adopts a variety of linkage vibrations, with a large molding area and high product density. 6.Servo frequency modulation drive control can be selected, with fast vibration start, short molding cycle and more accurate control. 7.Optional intelligent remote control electronic control can grasp the equipment operation status in real time, remotely control, operate, judge and solve equipment failures; online monitoring of the equipment operation status, online prediction and diagnosis of the equipment application operation and status. |

|---|