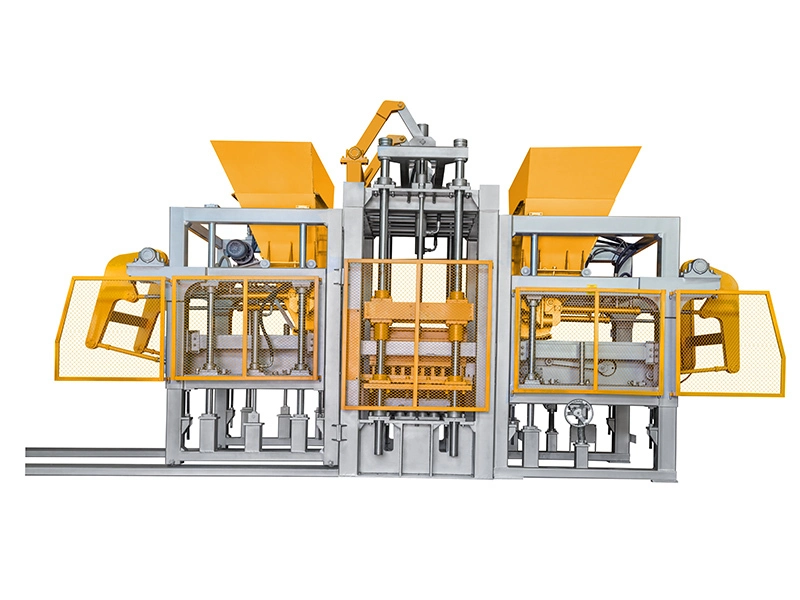

Yixin Machinery Popular Selling Premium Quality Automatic Heavy Duty Interlocking Paver Block Making Machine QT12-15

Place of Origin: China

Minimum order quantity: 1set

Color: Silver and yellow can be customzied

Material Science: Q235 Steel ,handox steel

Packing: Film

Delivery time: 25 working days

Model: QT12-15 heavy duty

Transaction mode: TT or 100%LC

Discharge port: Xiamen port

Tech Data

|

The dynamic and static vibration table on the Yixin QT12-15 paver block making machine is engineered for high-performance production. Its primary application is in manufacturing high-density, premium interlocking concrete pavers and heavy-duty blocks for commercial and municipal projects. The system utilizes dynamic vibration for efficient compaction of the concrete mix within the mold, ensuring a uniform texture and eliminating voids. Subsequently, the static vibration phase provides a final surface settlement, resulting in a smooth, precise finish on the block. This dual-action process is crucial for producing strong, dimensionally accurate, and visually consistent paving blocks that can withstand heavy traffic loads in areas like industrial yards, public roads, and urban landscapes.

The advance and retreat cushion pad is a critical component for the smooth operation of the QT12-15 block making machine. Its primary function is to absorb and dampen the high-impact forces generated during the mold's pressing and retraction cycles. This ensures a gentle, controlled descent and release onto the freshly formed paver blocks. By doing so, it effectively prevents surface cracks, edge chipping, and structural defects in the finished products. This cushioning action is vital for maintaining consistent product quality, especially when producing heavy-duty interlocking pavers. Furthermore, it significantly reduces vibration and mechanical stress on the machine's frame and hydraulic system, leading to less wear and tear, lower maintenance costs, and an extended overall service life for the equipment.

The long guide sleeves on the Yixin QT12-15 paver block machine are critical for high-volume, precision production. In a busy construction yard, the machine operates for extended periods, producing thousands of interlocking blocks daily. During this continuous operation, the long sleeves ensure the mold head moves with absolute stability and balance, preventing any lateral shift that could cause misshapen blocks or machine jams. Furthermore, the unique guiding bush that can be raised and lowered is periodically adjusted by the operator. This simple action changes the contact points, effectively distributing wear more evenly. This feature significantly reduces maintenance downtime and extends the overall service life of the machine, ensuring consistent output and lower operating costs over years of heavy-duty use.

|

|---|

|

Product Classification Description: Yixin Machinery Popular Selling Premium Quality Automatic Heavy Duty Interlocking Paver Block Making Machine QT12-1 Refer to : The QT12-15 automatic heavy-duty interlocking paver block making machine from Yixin Machinery is engineered for high-volume industrial production. Its primary application is in large-scale construction material manufacturing plants and precast yards that require a continuous output of premium-quality concrete pavers, bricks, and landscape blocks. The fully automatic system, with its robust design and high-pressure hydraulic system, ensures efficient, consistent, and reliable operation for mass-producing standardized construction elements. This machine is ideal for businesses supplying major infrastructure projects, municipal developments, commercial paving, and residential construction, where durability, dimensional accuracy, and high production capacity are critical. It represents a core asset for manufacturers aiming to optimize output and meet substantial market demand.

|

|---|

|

1.How many days to change vibration box oil ,what kind of oil can be used inside?

The hydraulic oil 68 degree can be used, the amount is from bottom 3cm. Strongly suggest 1 month change one time oil 2. How many hollow blocks can the Yixin Machinery QT12-15 produce per hour?

The QT12-15 can produce 2376 hollow blocks per hour, ensuring high productivity for your pavement block making needs. |

|---|

|

1.Adopting the best international design process, advanced technology. 2.Crank arm fabrication, fast and uniform. 3.Guide column dynamic demoulding mechanism, demoulding parallel and more accurate. 4.Suspended material cart, fabrication faster and more durable. 5.The vibration box adopts a variety of linkage vibrations, with a large molding area and high product density. 6.Servo frequency modulation drive control can be selected, with fast vibration start, short molding cycle and more accurate control. 7.Optional intelligent remote control electronic control can grasp the equipment operation status in real time, remotely control, operate, judge and solve equipment failures; online monitoring of the equipment operation status, online prediction and diagnosis of the equipment application operation and status. |

|---|