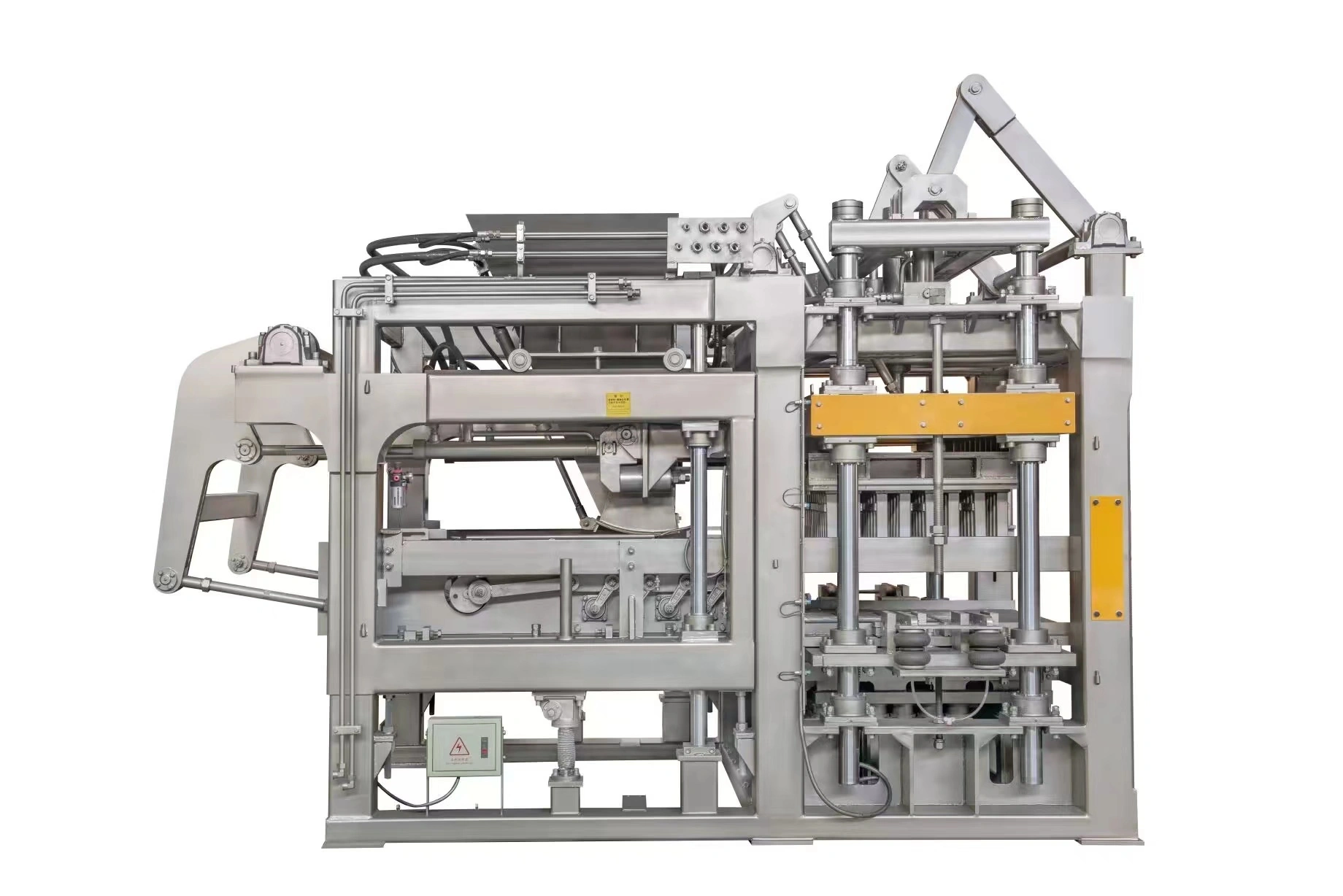

Yixin Machinery Professional Design Robust Quality Hydraulic Heavy Duty Cement Block Making Machine QT6-15

Place of Origin: China

Minimum order quantity: 1set

Color: Silver and yellow can be customzied

Material Science: Q235 Steel ,handox steel

Packing: Film

Delivery time: 25 working days

Model: QT6-15 heavy duty

Transaction mode: TT or 100%LC

Discharge port: Xiamen port

Tech Data

| ITEM | QT6-15HD |

|---|---|

| VIBRATION FREQUENCY | 3800-4500(T/S) |

| CYCLE TIME |

15-25(S) |

| VIBRATION FORCE | 95(KN) |

| VATED PRESSURE | 21(MPA) |

| POWER | 34.54(KW) |

| VIBRATION TYPE |

VIBRATION& PRESS |

|

The airbag mold locking system in the Yixin QT6-15 Hydraulic Block Making Machine is specifically engineered for high-volume, precision production environments. In industrial-scale cement block manufacturing plants, this feature proves invaluable. During the intense vibration and compaction phase, the airbag automatically applies uniform pressure to securely lock the mold in place. This action significantly minimizes mold displacement and dampens machine vibration. The result is a consistently stable molding process, which directly enhances the dimensional accuracy and structural integrity of every produced block. By reducing vibration transmission, the system also decreases wear on mechanical components, leading to lower maintenance needs and higher overall operational stability for continuous, heavy-duty operation.

The pressure meter adjustment for the airbag in the Yixin QT6-15 block making machine is a critical daily operation. It is primarily performed during machine setup and regular maintenance checks to ensure optimal performance. By accurately adjusting the airbag pressure via this meter, operators directly control the vibration intensity and compaction force during the molding cycle. This precise adjustment is essential for producing high-density, uniform concrete blocks with consistent quality and strength. Proper calibration ensures smooth demolding, protects the hydraulic system from uneven stress, and maintains the structural integrity of finished blocks. Correct pressure setting also enhances machine stability, reduces wear on components, and improves overall production efficiency.

The long guide sleeves on the Yixin QT6-15 cement block making machine are critical for high-volume, precision production environments. In a busy construction yard or block manufacturing plant, this machine operates for extended cycles under significant load from the hydraulic system. The extended sleeves ensure absolute vertical stability of the mold head during every compaction cycle, which is essential for producing blocks with consistent dimensions and sharp edges. The innovative feature where the guiding bush can be raised and lowered periodically distributes wear evenly across its surface. This dramatically reduces friction and premature wear, especially when processing abrasive concrete mixes.

|

|---|

|

Product Classification Description:Yixin Machinery Professional Design Robust Quality Hydraulic Heavy Duty Cement Block Making Machine QT6-15 Refer to: The Yixin Machinery QT6-15 Hydraulic Heavy Duty Cement Block Making Machine is engineered for high-volume, industrial-scale production in the construction materials sector. Its primary application is in large block yards and prefabrication plants that manufacture standard and customized cement blocks, pavers, interlocking bricks, and kerbstones. The robust QT6-15 is ideal for stable, continuous operation, efficiently producing dense, high-quality blocks for major infrastructure projects, commercial developments, and residential housing complexes. Its automatic hydraulic system ensures consistent output and durability, making it a cornerstone machine for businesses focused on supplying construction sites with reliable, structurally sound building components. It meets the demands of both fixed factory installations and large-scale, dedicated production lines.

|

|---|

| 1.What is the vibration frequency for Yixin Machinery Professional Design Robust Quality Hydraulic Heavy Duty Cement Block Making Machine QT6-15 ? The vibration frequency is 3800-4500(T/S) , making it highly efficient for producing curbstone and interlocking blocks. Efficient and fast production for all your construction needs.

2.How many liter hydraulic oil used?

68 degree hydraulic oil 600L request. 3.What is the estimated date of shipment for Yixin Machinery Professional Design Robust Quality Hydraulic Heavy Duty Cement Block Making Machine QT6-15 after mold confirmation?

|

|---|

| Production Of Raw Material: | ||

|---|---|---|

| Sand, gravel, cement, can add large of slag, coal gangue, clay, ceramisite, perlite and other | ||

| Applied Products: | ||

| Production of a variety of external wall block, internal wall block, PC stone permeable brick flower wall block, floor block, dike block, chain block, curb and other blocks. | ||

| Block Size: | ||

| 240*115*53mm 390*190*190mm 240*115*90mm 150*100*100mm 190*190*90mm 200*100*60mm and other |