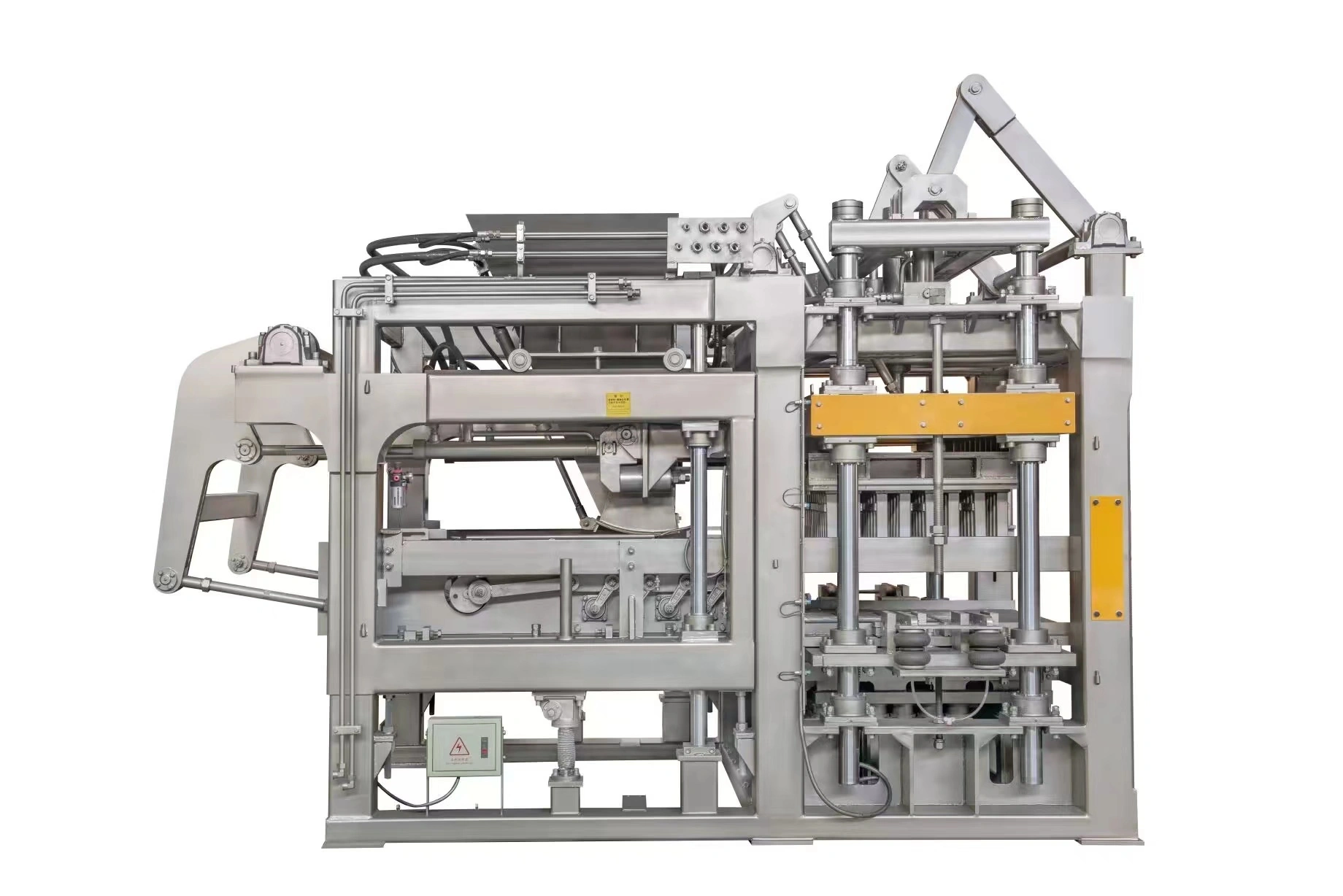

Yixin Machinery Professional Service Durable Quality Heavy Duty Customized Block Forming Machine QT10-15

Place of Origin: China

Minimum order quantity: 1set

Color: Blue and yellow can be customzied

Material Science: Q235 Steel ,handox steel

Packing: Film

Delivery time: 25 working days

Model: QT10-15 heavy duty

Transaction mode: TT or 100%LC

Discharge port: Xiamen port

Tech Data

|

The Yixin QT10-15 block forming machine, with its 90mm diameter guide cylinder and 400mm height bushing, is engineered for high-volume, precision production in demanding industrial settings. This robust configuration is essential for applications requiring exceptional stability and synchronization between the tamper head and mould frame. It is ideally suited for large-scale construction projects, precast concrete plants, and the manufacturing of high-strength paving blocks, interlocking bricks, and other standard or customized concrete products. The large guide cylinder and extended bushing work in tandem to eliminate lateral play, ensuring perfectly aligned and consistent vertical movement. This guarantees superior product dimensional accuracy, minimizes wear on components, and significantly enhances the machine's durability for continuous, heavy-duty operation.

The airbag mould change system on the Yixin QT10-15 block forming machine revolutionizes maintenance and production flexibility. Utilizing Germany's Continental brand airbags with a precise pressure control system, it allows a single operator to change and secure moulds quickly and safely. This system is ideal for manufacturers requiring frequent product switches, such as producing different-sized blocks or pavers. It significantly reduces downtime between production runs, enhances operational safety by minimizing manual handling, and ensures consistent mould alignment for superior product quality. This feature is essential for modern, high-output plants aiming for efficiency and versatility in concrete block manufacturing.

The automatic pallet provider for the Yixin QT10-15 block forming machine is an integral subsystem designed for seamless, high-volume production. Its primary function is to automatically supply empty pallets to the machine's molding area in a precise and timed sequence. This ensures a continuous, non-stop operation, eliminating manual handling and significantly boosting overall productivity. The system is engineered for robust performance, capable of handling the heavy-duty pallets required for high-density concrete blocks. It features reliable positioning mechanisms to guarantee accurate pallet placement every cycle. This automation is crucial for maintaining the machine's high output rate, reducing labor costs, and ensuring a consistent, efficient workflow for producing quality blocks.

|

|---|

|

Product Classification Description: Yixin Machinery Professional Service Durable Quality Heavy Duty Customized Block Forming Machine QT10-15 Refer to : The Yixin Machinery QT10-15 is a fully automatic, heavy-duty block forming machine engineered for high-volume production of diverse concrete blocks. Its core function is to efficiently manufacture standard and customized blocks, including hollow blocks, solid bricks, and interlocking pavers, with consistent dimensions and superior density. The machine features an automatic material batching system, a robust vibration and hydraulic pressure system for optimal compaction, and a precision mold that ensures product durability. Designed for continuous operation, the QT10-15 offers a high output rate with minimal manual intervention, making it an ideal solution for large-scale construction projects and industrial block yards. Its customizable nature allows for flexibility in product design while maintaining durable quality.

|

|---|

|

1.How many days to change vibration box oil ,what kind of oil can be used inside?

The hydraulic oil 68 degree can be used, the amount is from bottom 3cm. Strongly suggest 1 month change one time oil 2. How many hollow blocks can the Yixin Machinery QT10-15 produce per hour?

The QT10-15 can produce 1980 hollow blocks per hour, ensuring high productivity for your pavement block making needs. |

|---|