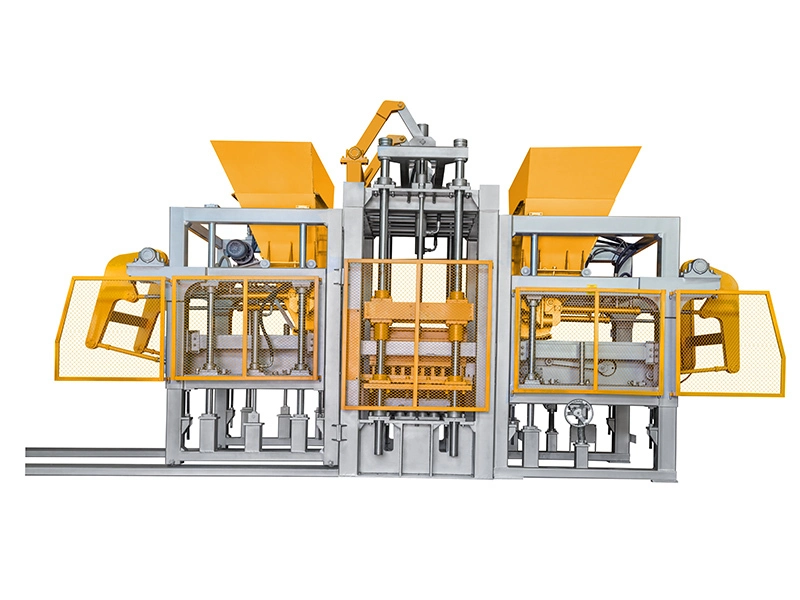

Yixin Machinery Professional Service Fully Set Robust Heavy Duty Hollow Block Making Machine QT12-15

Place of Origin: China

Minimum order quantity: 1set

Color: Silver and yellow can be customzied

Material Science: Q235 Steel ,handox steel

Packing: Film

Delivery time: 25 working days

Model: QT12-15 heavy duty

Transaction mode: TT or 100%LC

Discharge port: Xiamen port

Tech Data

|

The Automatic Pallet Provider for the Yixin QT12-15 block making machine is a fully integrated subsystem designed for seamless, high-volume production. Its primary function is to automatically supply pallets to the machine's feeding station, ensuring a continuous and non-stop operation. This system precisely positions each pallet for the concrete block molding process. By eliminating manual pallet handling, it significantly boosts overall production efficiency and output consistency. The mechanism is engineered for robust performance, synchronizing perfectly with the machine's high-speed cycling to maintain a smooth workflow. This automation is crucial for maximizing the productivity of the QT12-15, reducing labor requirements, and ensuring a safe, uninterrupted manufacturing process for high-quality hollow blocks.

The QT12-15 block making machine incorporates long guide sleeves as a core component of its robust framework. These sleeves are fundamental in providing exceptional stability and balance to the entire system during the high-pressure vibration and compaction processes. This precise guidance ensures that the machine's moving parts operate in perfect alignment, which is critical for producing consistently high-quality blocks with dimensional accuracy. A significant feature is that the guiding bush can be raised and lowered. This adjustability is a key design innovation that actively minimizes uneven wear on the components. By distributing the wear more evenly, this feature substantially extends the service life of the guiding mechanism, reducing long-term maintenance costs and enhancing the machine's overall durability and operational reliability.

The Yixin QT12-15 Hollow Block Making Machine integrates robust functionality with durable design. A key feature is its wear-resistant copper sleeves, which provide a smooth operation for the machine's movement. These sleeves effectively protect the guide pillars from damage, ensuring long-term precision and reducing maintenance needs. Furthermore, the machine is equipped with strategically arranged stirring teeth. This row-based configuration of the mixing arms ensures a consistent and rapid distribution of raw materials. This design facilitates quick and efficient feeding directly into the mold, significantly optimizing the overall production cycle and output quality.

|

|---|

|

Product Classification Description: Yixin Machinery Professional Service Fully Set Robust Heavy Duty Hollow Block Making Machine QT12-15 Refer to : The QT12-15 from Yixin Machinery is a fully automatic, robust block making machine designed for high-volume production. Its core function is to manufacture high-quality hollow blocks and various other concrete products with precision and efficiency. The machine features a powerful vibration system and a rigid frame structure, ensuring dense compaction and consistent product durability. Operating with a 15-second cycle time, it can produce up to 12 blocks per cycle (400x200x200mm), achieving impressive output. This fully set system integrates mixing, conveying, molding, and stacking, streamlining the entire process. It is an ideal solution for large-scale construction projects and industrial brick-making plants, offering exceptional reliability and low maintenance for continuous, heavy-duty operation.

|

|---|

|

1.How many days to change vibration box oil ,what kind of oil can be used inside?

The hydraulic oil 68 degree can be used, the amount is from bottom 3cm. Strongly suggest 1 month change one time oil 2. How many hollow blocks can the Yixin Machinery QT12-15 produce per hour?

The QT12-15 can produce 2376 hollow blocks per hour, ensuring high productivity for your pavement block making needs. |

|---|