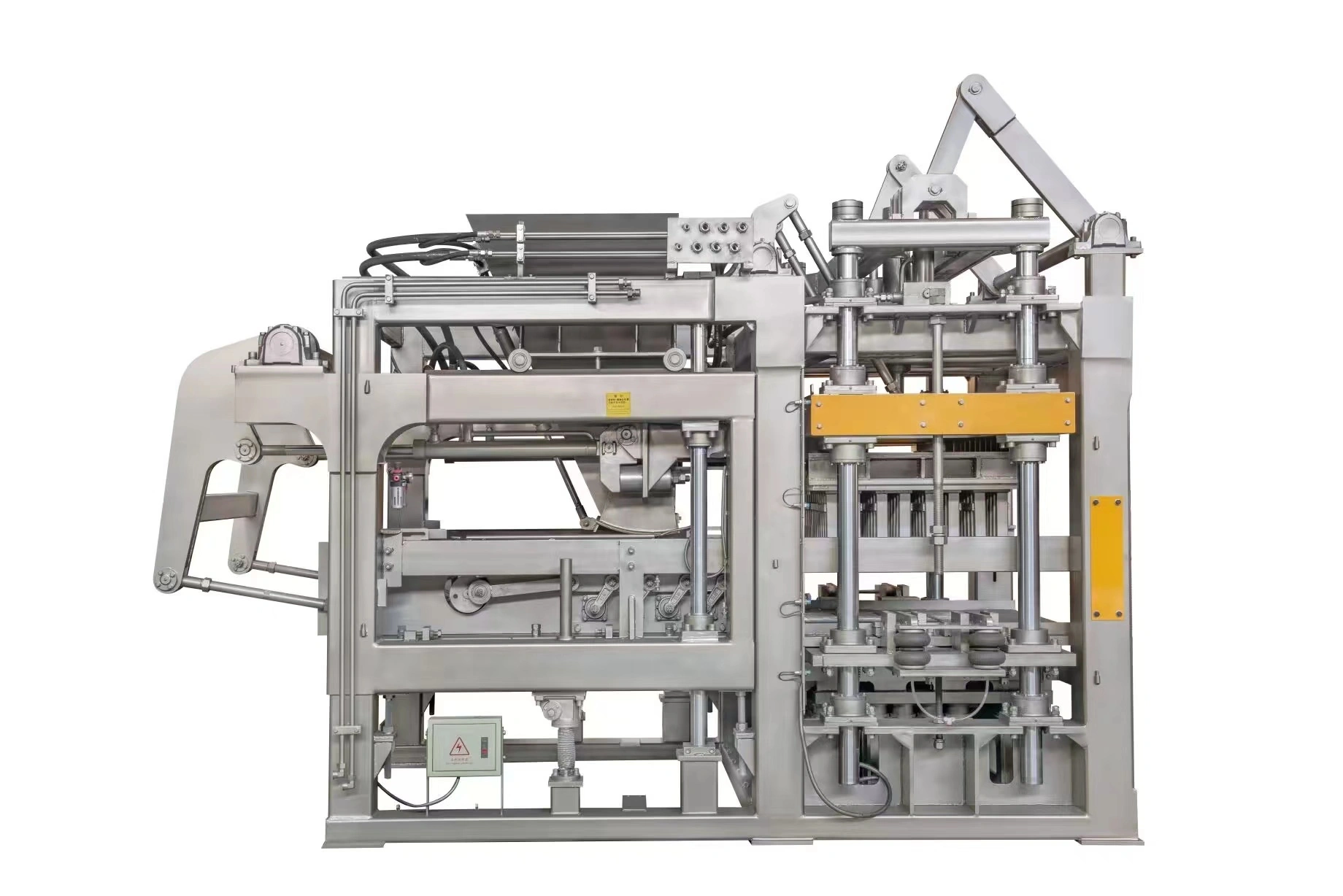

Yixin Machinery Professional Service High Accuracy Durable Heavy Duty Sand Block Forming Machine QT10-15

Place of Origin: China

Minimum order quantity: 1set

Color: Blue and yellow can be customzied

Material Science: Q235 Steel ,handox steel

Packing: Film

Delivery time: 25 working days

Model: QT10-15 heavy duty

Transaction mode: TT or 100%LC

Discharge port: Xiamen port

Tech Data

|

The QT10-15 block forming machine from Yixin Machinery utilizes a unique beating formation method for brick production. In this process, the static table is precisely set 3 mm lower than the dynamic table. This specific technical feature ensures the bricks are compacted with exceptional density and structural integrity. This high-density formation makes the machine particularly suitable for manufacturing high-quality colored bricks and high-strength bricks. Its primary application is in industrial brick production plants that require durable, precision-engineered concrete products for demanding construction projects. These include paving projects for urban landscapes, high-grade architectural facades, and heavy-duty infrastructure where superior surface finish and long-term durability are critical. The machine is ideal for producers aiming for a premium product line.

The wear-resistant copper sleeves in the Yixin Machinery QT10-15 Sand Block Forming Machine are engineered for demanding industrial production environments. In a high-cycle block manufacturing plant, these sleeves are crucial for the continuous operation of the machine's mold system. They act as a durable, low-friction interface between moving parts and the guide pillars, ensuring perfect alignment during the intense vibration and pressure of the concrete compaction process. Their exceptional wear resistance guarantees a long service life, significantly reducing the frequency of maintenance shutdowns. Most importantly, the soft yet tough nature of the copper material effectively protects the hardened steel guide pillars from scoring, galling, or premature wear. This not only preserves the critical precision of the machine but also eliminates the substantial replacement costs associated with damaged pillars, ensuring smooth and cost-effective long-term operation.

The advance and retreat cushion pad in the Yixin QT10-15 Sand Block Forming Machine is a critical component for ensuring smooth and precise mold movement. Its primary application is within the machine's hydraulic system, where it controls the deceleration of the mold platform as it approaches the sand block and the initial acceleration as it retracts. This precise cushioning action is vital during the high-pressure compaction cycle to form concrete blocks. By absorbing kinetic energy and preventing harsh mechanical impacts, the pad protects the mold, the hydraulic cylinders, and the entire frame from stress damage. This directly minimizes maintenance needs, reduces operational noise, and guarantees consistent block quality and dimensional accuracy. Ultimately, it enhances the machine's durability and reliability in continuous, heavy-duty production environments.

|

|---|

|

Product Classification Description: Yixin Machinery Professional Service High Accuracy Durable Heavy Duty Sand Block Forming Machine QT10-15 Refer to :The Yixin Machinery QT10-15 Sand Block Forming Machine is engineered for large-scale, high-volume production in the construction materials industry. Its primary application is in manufacturing a wide range of high-precision, durable concrete blocks, including standard bricks, hollow blocks, interlocking pavers, and curbstones. This heavy-duty machine is ideal for established block yards and precast concrete plants that supply major commercial, industrial, and infrastructure projects. The QT10-15 automates the entire process of molding, pressing, and curing, ensuring consistent product quality and dimensional accuracy for structural integrity. Its robust design guarantees continuous operation and minimal downtime, making it a cost-effective solution for meeting the high demands of urban development and large construction contracts. The machine excels in producing uniform blocks that are essential for efficient, speed-driven building techniques.

|

|---|

|

1.How many days to change vibration box oil ,what kind of oil can be used inside?

The hydraulic oil 68 degree can be used, the amount is from bottom 3cm. Strongly suggest 1 month change one time oil 2. How many hollow blocks can the Yixin Machinery QT10-15 produce per hour?

The QT10-15 can produce 1980 hollow blocks per hour, ensuring high productivity for your pavement block making needs. |

|---|

| Production Of Raw Material: | ||

|---|---|---|

| Sand, gravel, cement, can add large of slag, coal gangue, clay, ceramisite, perlite and other | ||

| Applied Products: | ||

| Production of a variety of external wall block, internal wall block, PC stone permeable brick flower wall block, floor block, dike block, chain block, curb and other blocks. | ||

| Block Size: | ||

| 240*115*53mm 390*190*190mm 240*115*90mm 150*100*100mm 190*190*90mm 200*100*60mm and other |