dedication, hard work, integrity, gratitude and innovation

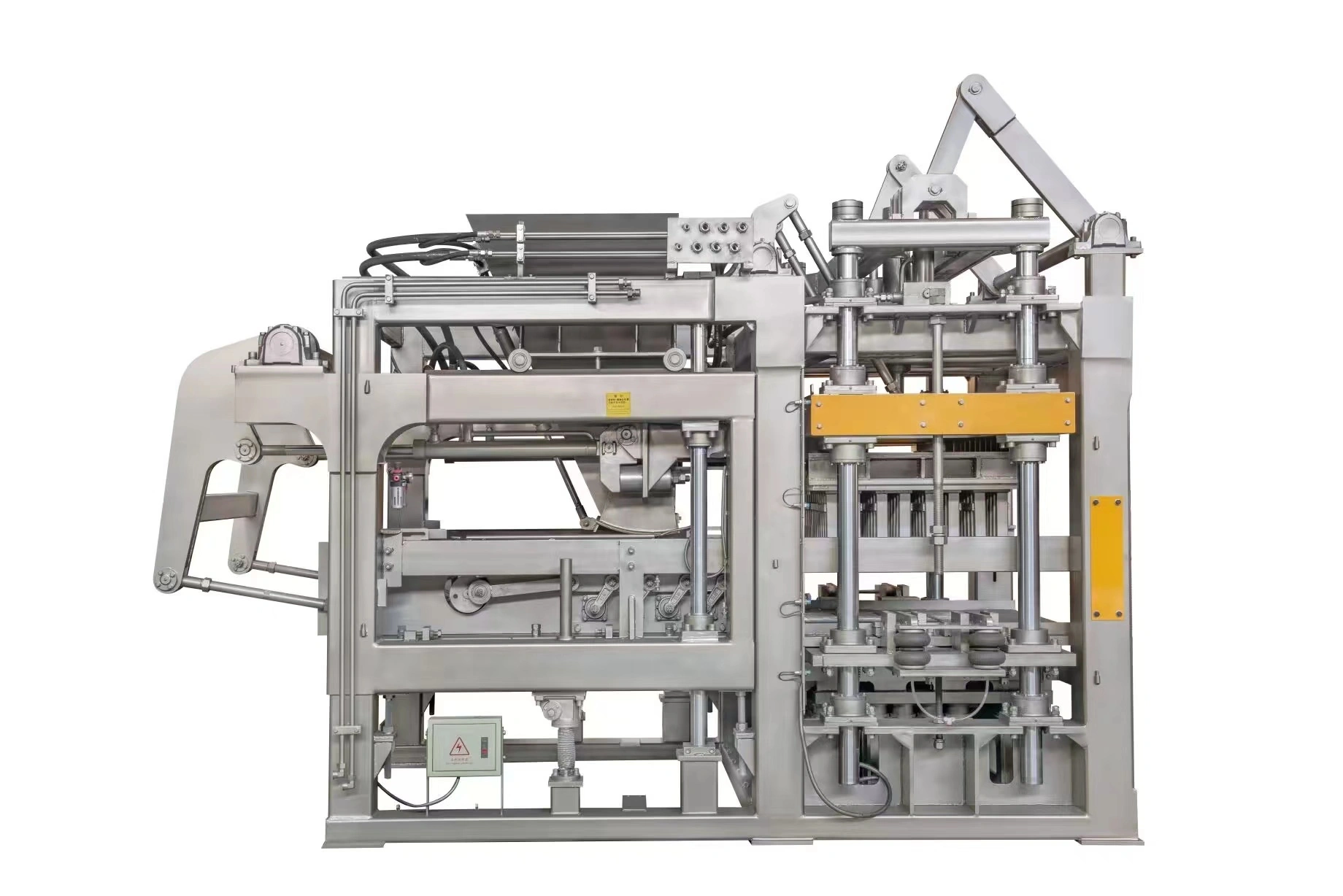

Yixin Machinery Quality Assurance Fully Set Heavy Duty Hydraulic Zigzag Paver Block Making Machine QT6-15

Place of Origin: China

Minimum order quantity: 1set

Color: Silver and yellow can be customzied

Material Science: Q235 Steel ,handox steel

Packing: Film

Delivery time: 25 working days

Model: QT6-15 heavy duty

Transaction mode: TT or 100%LC

Discharge port: Xiamen port

Tech Data

| ITEM | QT6-15HD |

|---|---|

| VIBRATION FREQUENCY | 3800-4500(T/S) |

| CYCLE TIME |

15-25(S) |

| VIBRATION FORCE | 95(KN) |

| VATED PRESSURE | 21(MPA) |

| POWER | 34.54(KW) |

| VIBRATION TYPE |

VIBRATION& PRESS |

|

The airbag system in the Yixin QT6-15 hydraulic paver block making machine is designed to securely lock the mold in place during the high-pressure compaction process. This feature is essential in demanding production environments, such as large-scale construction material factories and infrastructure projects, where consistent output of high-strength concrete blocks is required. By effectively reducing vibration and stabilizing the mold, the airbag mechanism ensures superior product dimensional accuracy and surface finish. It significantly minimizes material waste and downtime, making the machine ideal for continuous, heavy-duty operation in manufacturing precast pavers, curbstones, and other concrete products.

The demolding synchronize feature of the Yixin Machinery QT6-15 hydraulic paver block making machine significantly enhances production efficiency in high-volume industrial settings. By ensuring that the demolding process is both faster and more stable, it minimizes cycle times and maximizes output for construction material manufacturers and large-scale paving projects. This reliability is crucial for producing consistent, high-quality concrete blocks, bricks, and interlocking pavers with minimal downtime or defect rates. The stable operation also reduces wear on the machine, leading to lower long-term maintenance costs and greater operational continuity for businesses focused on meeting tight deadlines and large orders.

The servo hydraulic system in the Yixin QT6-15 paver block making machine is engineered for high-efficiency production scenarios. It provides precise and consistent hydraulic pressure during operation, which is essential for manufacturing uniform, high-density concrete blocks. This system significantly reduces energy consumption by operating on demand, rather than running continuously. The enhanced control allows for more accurate mold filling and vibration, leading to superior product quality with minimal material waste. Ideal for large-scale industrial use, it ensures reliable performance while lowering operational costs and supporting sustainable manufacturing practices.

|

|---|

|

Product Classification Description: Yixin Machinery Quality Assurance Fully Set Heavy Duty Hydraulic Zigzag Paver Block Making Machine QT6-15 Refer to: The Yixin Machinery QT6-15 is a fully automatic, heavy-duty hydraulic machine engineered for high-volume production of premium zigzag paver blocks. Its primary application is in large-scale construction projects and industrial precast plants that require efficient, continuous output of high-strength paving solutions. Ideal for manufacturing interlocking blocks for roadways, parking lots, industrial flooring, and public spaces like ports and logistics yards, this robust system ensures consistent quality and dimensional accuracy. The automated operation minimizes labor while maximizing productivity, making it a cornerstone asset for businesses specializing in concrete products and infrastructure development.

|

|---|

| 1.What is the vibration frequency for Yixin Machinery Quality Assurance Fully Set Heavy Duty Hydraulic Zigzag Paver Block Making Machine QT6-15 ? The vibration frequency is 3800-4500(T/S) , making it highly efficient for producing curbstone and interlocking blocks. Efficient and fast production for all your construction needs.

2.How many liter hydraulic oil used?

68 degree hydraulic oil 600L request. 3.What is the estimated date of shipment for Yixin Machinery Quality Assurance Fully Set Heavy Duty Hydraulic Zigzag Paver Block Making Machine QT6-15 after mold confirmation?

|

|---|

to achieve customers, brands and employees

quality first, performance first, service first

internationalization, branding and specialization