dedication, hard work, integrity, gratitude and innovation

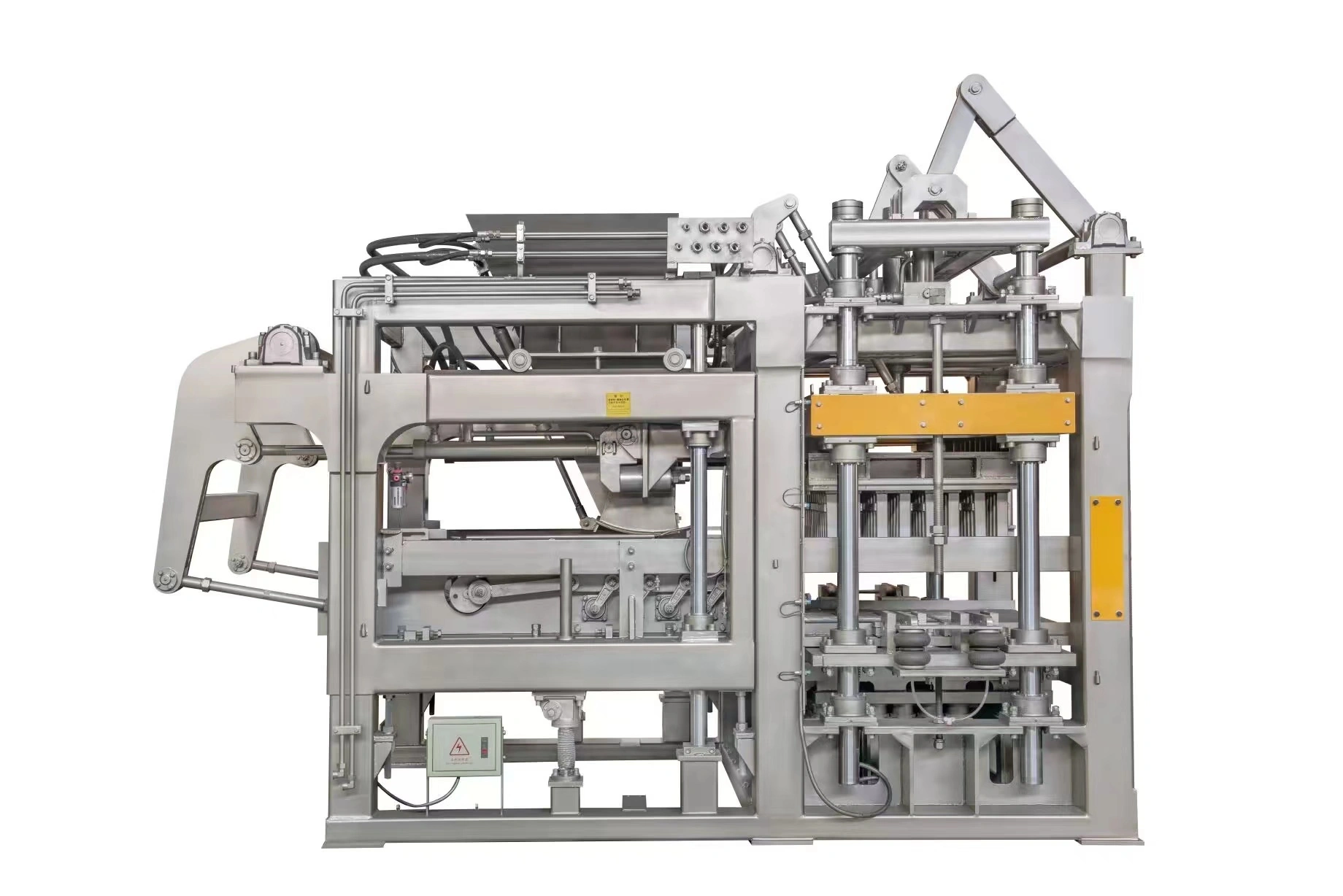

Yixin Machinery Quality Assurance Fully Set Heavy Duty Ripple Shape Paver Block Making Machine QT6-15

Place of Origin: China

Minimum order quantity: 1set

Color: Silver and yellow can be customzied

Material Science: Q235 Steel ,handox steel

Packing: Film

Delivery time: 25 working days

Model: QT6-15 heavy duty

Transaction mode: TT or 100%LC

Discharge port: Xiamen port

Tech Data

| ITEM | QT6-15HD |

|---|---|

| VIBRATION FREQUENCY | 3800-4500(T/S) |

| CYCLE TIME |

15-25(S) |

| VIBRATION FORCE | 95(KN) |

| VATED PRESSURE | 21(MPA) |

| POWER | 34.54(KW) |

| VIBRATION TYPE |

VIBRATION& PRESS |

|

The Yixin QT6-15 paver block making machine features advanced wear-resistant strips designed for quick and convenient replacement and maintenance. Unlike traditional integral cast steel components, these strips simplify servicing, significantly reducing machine downtime. Additionally, the machine is equipped with durable wear-resistant copper sleeves. These sleeves provide superior protection to the guide pillars during operation, preventing damage and ensuring smooth, precise movement. This combination of easily maintainable strips and protective copper sleeves enhances the machine's durability, operational efficiency, and long-term reliability.

The pressure meter on the Yixin QT6-15 block making machine is a critical control for optimizing production. It allows the operator to precisely monitor and adjust the airbag pressure within the system. This regulation is essential for applying the correct compaction force to the concrete mix. By fine-tuning this pressure, the machine ensures each heavy-duty ripple shape paver block is formed with uniform high density, superior strength, and a consistent, sharp surface finish. Proper adjustment guarantees product quality, maximizes output, and contributes to the machine's reliable and efficient operation.

The advance and retreat cushion pad on the Yixin QT6-15 block making machine is a critical component designed to ensure smooth and stable operation. It provides effective buffering for the feeding car during its forward and backward movements, significantly reducing impact and mechanical vibration. This damping action not only protects the machine's structural integrity by minimizing stress but also contributes to a more consistent production process. The result is enhanced equipment durability, reduced maintenance needs, and higher quality finished paver blocks with precise dimensions and a uniform appearance.

|

|---|

|

Product Classification Description: Yixin Machinery Quality Assurance Fully Set Heavy Duty Ripple Shape Paver Block Making Machine QT6-15 Refer to: The Yixin Machinery QT6-15 is a fully automatic, heavy-duty block making machine designed for high-volume production of premium ripple-shaped paver blocks. Its core function is to efficiently compress concrete into precise, interlocking shapes through a robust vibration system and a large QT6 mold. Operating on a standard 15-second cycle, it can produce up to 6,720 solid blocks in an eight-hour shift. The integrated quality assurance system ensures consistent product density, superior strength, and a uniform surface finish. This self-contained unit, complete with a cement silo and conveyor, is engineered for continuous, reliable operation with minimal manual intervention, making it ideal for large-scale infrastructure and landscaping projects.

|

|---|

| 1.What is the vibration frequency for Yixin Machinery Quality Assurance Fully Set Heavy Duty Ripple Shape Paver Block Making Machine QT6-15 ? The vibration frequency is 3800-4500(T/S) , making it highly efficient for producing curbstone and interlocking blocks. Efficient and fast production for all your construction needs.

2.How many liter hydraulic oil used?

68 degree hydraulic oil 600L request. 3.What is the estimated date of shipment for Yixin Machinery Quality Assurance Fully Set Heavy Duty Ripple Shape Paver Block Making Machine QT6-15 after mold confirmation?

|

|---|

to achieve customers, brands and employees

quality first, performance first, service first

internationalization, branding and specialization