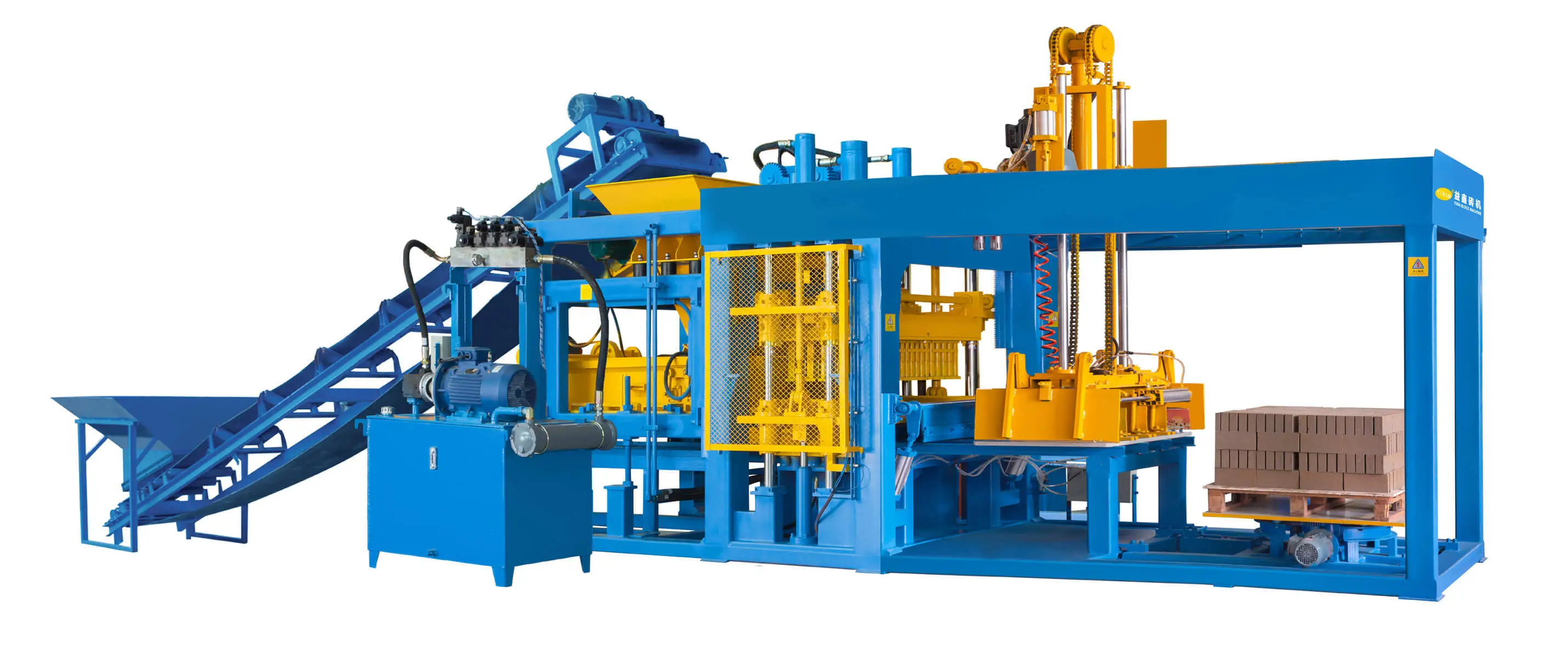

Yixin Machinery Quality Certification Fully Automatic High Efficiency Free Pallet Sand Block Making Machine QTMT12-15

Place of Origin: China

Minimum order quantity: 1set

Color: Blue and yellow can be customzied

Material Science: Q235 Steel ,handox steel

Packing: Film

Delivery time: 25 working days

Model: QTMT 12-15

Transaction mode: TT or 100%LC

Discharge port: Xiamen port

TECH DATA

|

The raw material hopper of the Yixin QTMT12-15 block making machine is designed for efficient and continuous material supply. Constructed from robust steel, it features a large capacity to hold a consistent volume of raw materials like sand, cement, and fly ash. Its internal structure is engineered to prevent material arching and bridging, ensuring a smooth, uninterrupted flow to the mixing system. The hopper is equipped with a feed control gate to precisely regulate the discharge rate, which is crucial for maintaining the correct ratio in the mixer and ensuring product uniformity. This design is integral to the machine's fully automated, high-efficiency operation.

The high durable bar in the Yixin QTMT12-15 block making machine is a core component engineered for exceptional longevity and performance. It functions as the central drive shaft, transmitting powerful hydraulic pressure from the main system to the mold head. This force is essential for the high-pressure compaction of raw materials like concrete and sand, ensuring the production of dense, precisely formed blocks with superior structural integrity. Manufactured from specially hardened and tempered alloy steel, the bar is highly resistant to bending, warping, and wear under continuous heavy-load operation. Its robust design is critical for maintaining machine stability, minimizing downtime for maintenance, and guaranteeing consistent production efficiency over the long term.

The hydraulic unit of the Yixin QTMT12-15 block making machine is the core of its operation, engineered for high reliability and efficiency. It delivers consistent and powerful pressure to ensure the production of dense, high-quality concrete blocks and pavers. The system features precision control for smooth mold vibration and compaction, resulting in products with superior surface finish and structural integrity. Its energy-efficient design minimizes power consumption, while robust components ensure durability and a long service life with minimal maintenance requirements. This advanced hydraulic system guarantees stable performance and fully automated, uninterrupted production cycles. |

|---|

| Product Classification Description :Yixin Machinery Quality Certification Fully Automatic High Efficiency Free Pallet Sand Block Making Machine QTMT12-15

Refer to :The QTMT12-15 from Yixin Machinery is a fully automatic, high-efficiency block making machine designed for mass production. Its key feature is a free-pallet system that eliminates the need for wooden pallets, significantly reducing production costs and maintenance. The machine is capable of producing a wide variety of concrete products, including hollow blocks, solid bricks, and interlocking pavers, with consistent high quality. Engineered for robust performance and easy operation, it offers superior automation for streamlined workflow. This model is an ideal solution for large-scale construction projects, ensuring optimal productivity and durability for all block manufacturing needs.

|

|---|

|

1.What is the host machine power of Yixin Machinery Quality Certification Fully Automatic High Efficiency Free Pallet Sand Block Making Machine QTMT12-15 ?

The host machine power is 58 (KW), ensuring thorough and efficient compaction for high-quality clay block production.

2.How many hollow blocks can Yixin Machinery Quality Certification Fully Automatic High Efficiency Free Pallet Sand Block Making Machine QTMT12-15 produce in a class?

The machine can output 46080-61440 hollow blocks in just 8 hours, making it a highly efficient and productive choice for clay block manufacturing.

3.How many days to change vibration box oil ,what kind of oil can be used inside?

The hydraulic oil 68 degree can be used, the amount is from bottom 3cm. Strongly suggest 1 month change one time oil.

|

|---|

|

1.The no-seam connection of he own research control system. the hydraulic system and equipment, to realize the integrative Technique of mechanics-electronics hydraulics and efficient oper. |

|---|