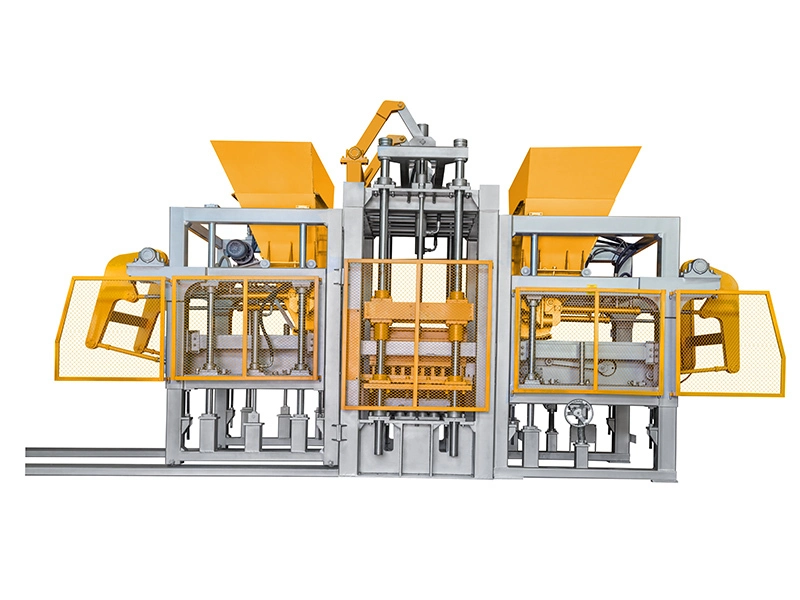

Yixin Machinery Quality Certification More Durable Heavy Duty Hollow Block Making Machine QT12-15

Place of Origin: China

Minimum order quantity: 1set

Color: Silver and yellow can be customzied

Material Science: Q235 Steel ,handox steel

Packing: Film

Delivery time: 25 working days

Model: QT12-15 heavy duty

Transaction mode: TT or 100%LC

Discharge port: Xiamen port

Tech Data

|

The pressure meter for adjusting the airbag pressure on the Yixin QT12-15 hollow block making machine is a critical control point for daily operation. Its primary use occurs during machine setup and production material changes. Operators monitor and calibrate the air pressure to ensure the molding head applies consistent and optimal force to the concrete mix. Correct pressure is vital for producing high-density blocks with sharp edges and superior structural integrity. It also prevents material waste and potential damage to the mold. Regular checks and precise adjustments via this meter guarantee the machine operates at peak efficiency, delivering durable, heavy-duty blocks while maintaining the equipment's longevity and reliability.

The wear-resistant strips on the Yixin QT12-15 block making machine are designed for scenarios demanding high-volume, continuous production of concrete blocks. In such intensive operations, machinery components are subject to constant friction and wear. The key advantage of these strips is their design for convenient replacement and maintenance. When wear occurs, operators can quickly swap out the individual strips without needing to dismantle major sections of the equipment. This stands in contrast to older integral cast steel designs, where replacing a worn section was often a complex and time-consuming process. This feature significantly reduces machine downtime for maintenance, ensuring higher operational efficiency and more consistent output for construction material suppliers and large-scale precast concrete plants.

The flexible feeding arm on the Yixin QT12-15 block making machine is a key component designed for enhanced operational stability in industrial production. Its primary function is to automatically and precisely push the material cart during the concrete block manufacturing process. This system ensures a consistent and smooth supply of raw materials, such as concrete mix, from the preparation station to the molding area of the machine. By automating the cart transfer, it eliminates manual pushing, reduces labor intensity, and minimizes the risk of material spillage. The arm's flexible and stable motion guarantees that the cart moves evenly along its track, which is crucial for maintaining a continuous production flow. This results in higher efficiency, reduced downtime, and more uniform quality for the heavy-duty hollow blocks produced.

|

|---|

|

Product Classification Description: Yixin Machinery Quality Certification More Durable Heavy Duty Hollow Block Making Machine QT12-15 Refer to : The QT12-15 heavy-duty block making machine from Yixin Machinery is engineered for large-scale, high-volume production environments. Its primary application is in industrial construction material manufacturing plants and permanent block yards that supply major building projects. The machine's robust design and certified quality ensure continuous, reliable operation for producing a wide range of hollow blocks, paver blocks, and other standard concrete products. It is perfectly suited for meeting the substantial material demands of infrastructure development, commercial construction, and large residential complexes. By automating the molding and compacting process, it delivers superior output consistency and structural integrity, making it an ideal capital investment for businesses focused on durable, high-strength building materials for heavy-use applications.

|

|---|

|

1.How many days to change vibration box oil ,what kind of oil can be used inside?

The hydraulic oil 68 degree can be used, the amount is from bottom 3cm. Strongly suggest 1 month change one time oil 2. How many hollow blocks can the Yixin Machinery QT12-15 produce per hour?

The QT12-15 can produce 2376 hollow blocks per hour, ensuring high productivity for your pavement block making needs. |

|---|