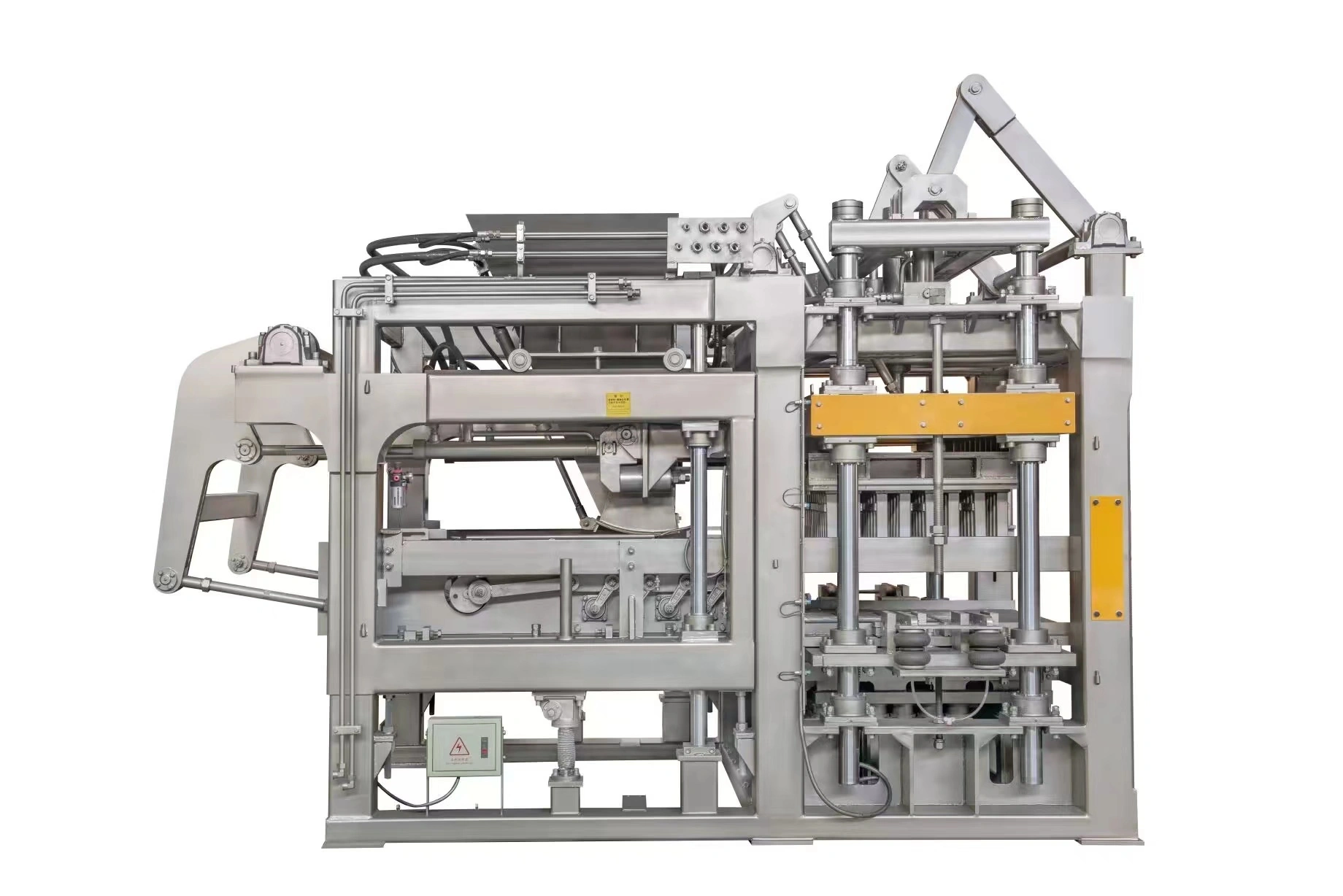

Yixin Machinery Quality Service Premium High Durable Heavy Duty Colorful Block Forming Machine QT10-15

Place of Origin: China

Minimum order quantity: 1set

Color: Blue and yellow can be customzied

Material Science: Q235 Steel ,handox steel

Packing: Film

Delivery time: 25 working days

Model: QT10-15 heavy duty

Transaction mode: TT or 100%LC

Discharge port: Xiamen port

Tech Data

|

The servo hydraulic system in the Yixin QT10-15 block forming machine is engineered for high-efficiency industrial production. It provides precise, on-demand hydraulic pressure only when the machine is in operation, significantly reducing energy consumption compared to standard systems. This intelligent power management allows for exceptionally accurate control of the mold and block ejection processes. The result is a machine that runs with superior stability, produces consistently high-quality concrete blocks, and achieves notable savings on electricity costs, making it ideal for large-scale, continuous manufacturing plants.

The automatic pallet feeder on the Yixin QT10-15 block forming machine is engineered for high-volume production environments. It seamlessly integrates with the system to automatically supply and position pallets for the continuous molding of colorful blocks. This eliminates manual handling, significantly boosting output and operational efficiency. It is an indispensable component for large-scale construction projects, precast concrete plants, and any operation focused on maximizing productivity and maintaining a consistent, uninterrupted production flow for durable, high-quality blocks.

The dynamic and static vibration system of the QT10-15 block forming machine is engineered for superior performance in high-volume production environments. The dynamic table efficiently distributes and consolidates raw concrete mix, ensuring optimal density and homogeneity within the mold. This process is critical for achieving high structural integrity and precise dimensional accuracy in finished blocks, pavers, and bricks. The subsequent action of the static table provides stability, settling the material to eliminate internal voids and air pockets. This dual-system is essential for manufacturing premium, load-bearing construction materials with consistent quality and a flawless surface finish, making it ideal for large-scale infrastructure and commercial projects.

|

|---|

|

Product Classification Description: Yixin Machinery Quality Service Premium High Durable Heavy Duty Colorful Block Forming Machine QT10-15 Refer to :The QT10-15 from Yixin Machinery is an automated, high-capacity block making machine designed for large-scale industrial production. Its primary application is in the manufacturing of a wide array of concrete products, including standard solid/hollow blocks, interlocking pavers, and curbstones. Ideal for major construction projects, precast plants, and export-oriented building material businesses, it excels in producing consistent, high-strength components for infrastructure, commercial buildings, and residential developments. The machine's durability and colorful output capability also make it suitable for producing decorative landscaping elements. Its fully automatic operation ensures efficiency for continuous, high-volume output demands.

|

|---|

|

1.How many days to change vibration box oil ,what kind of oil can be used inside?

The hydraulic oil 68 degree can be used, the amount is from bottom 3cm. Strongly suggest 1 month change one time oil 2. How many hollow blocks can the Yixin Machinery QT10-15 produce per hour?

The QT10-15 can produce 1980 hollow blocks per hour, ensuring high productivity for your pavement block making needs. |

|---|

|

1.Adopting the best international design process, advanced technology. 2.Crank arm fabrication, fast and uniform. 3.Guide column dynamic demoulding mechanism, demoulding parallel and more accurate. 4.Suspended material cart, fabrication faster and more durable. 5.The vibration box adopts a variety of linkage vibrations, with a large molding area and high product density. 6.Servo frequency modulation drive control can be selected, with fast vibration start, short molding cycle and more accurate control. 7.Optional intelligent remote control electronic control can grasp the equipment operation status in real time, remotely control, operate, judge and solve equipment failures; online monitoring of the equipment operation status, online prediction and diagnosis of the equipment application operation and status. |

|---|