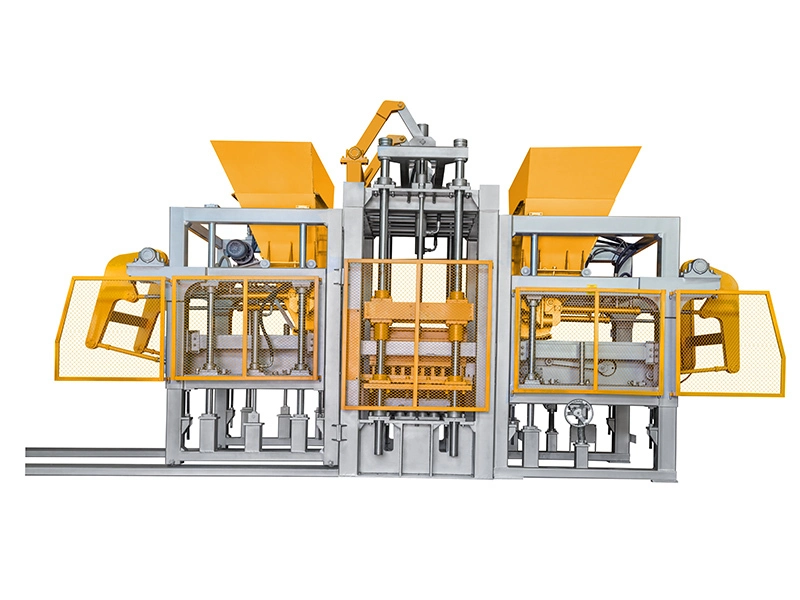

Yixin Machinery Quality Wholesale Fully Set Hydraulic Heavy Duty Sand Block Making Machine QT12-15

Place of Origin: China

Minimum order quantity: 1set

Color: Silver and yellow can be customzied

Material Science: Q235 Steel ,handox steel

Packing: Film

Delivery time: 25 working days

Model: QT12-15 heavy duty

Transaction mode: TT or 100%LC

Discharge port: Xiamen port

Tech Data

|

The PLC control unit in the Yixin QT12-15 hydraulic sand block making machine serves as the central intelligence for the entire production line. Its key advantages include superior automation, ensuring consistent and precise control over all machine actions and processes. This results in high operational stability and reliable output quality. The system is user-friendly, allowing for easy parameter adjustments and troubleshooting, which minimizes downtime. Furthermore, the robust PLC enhances equipment safety by monitoring operations and preventing errors. Its efficient process management maximizes productivity while reducing manual labor and the potential for human error, making it a cornerstone for a modern, high-capacity block manufacturing facility.

The wear-resistant strips on the Yixin QT12-15 block making machine offer significant advantages over traditional integral cast steel designs. Their primary benefit is the exceptional convenience they bring to replacement and maintenance routines. Unlike a single, heavy cast steel component, these individual strips can be replaced quickly and independently when worn. This modular approach drastically reduces machine downtime for servicing. Furthermore, it lowers long-term operational costs, as only the specific worn strips need to be purchased instead of a large, expensive integral part. This design ensures optimal machine performance and longevity with minimal maintenance effort, making it a highly practical and cost-effective solution for high-volume production environments.

The automatic pallet provider integrated into the Yixin QT12-15 block making machine offers significant advantages for high-volume production. It ensures a continuous, uninterrupted workflow by automatically supplying pallets to the production line. This eliminates the need for manual pallet handling, which directly reduces labor costs and minimizes the risk of workplace injuries. The system maintains a consistent and precise cycle time, leading to a remarkable increase in overall output and production efficiency. Furthermore, the automated process guarantees perfect alignment of each pallet, which is crucial for achieving superior product dimensional accuracy and a consistent, high-quality finish on every block. This results in a more streamlined, profitable, and reliable manufacturing operation.

|

|---|

|

Product Classification Description:Yixin Machinery Quality Wholesale Fully Set Hydraulic Heavy Duty Sand Block Making Machine QT12-15 Refer to : The Yixin Machinery QT12-15 is a fully hydraulic, heavy-duty block making machine designed for high-volume production. Its core function is to automatically manufacture a wide range of sand-cement blocks, bricks, and pavers with consistent quality and superior density. The fully hydraulic system ensures powerful compression, resulting in products with high strength and precise dimensional accuracy. This model features an automatic feeding system, block ejection, and pallet return, enabling efficient, continuous operation with minimal manual labor. The QT12-15 is capable of producing various hollow blocks, solid bricks, and interlocking paving stones, making it an ideal and versatile solution for large-scale wholesale construction projects and industrial precast plants.

|

|---|

|

1.How many days to change vibration box oil ,what kind of oil can be used inside?

The hydraulic oil 68 degree can be used, the amount is from bottom 3cm. Strongly suggest 1 month change one time oil 2. How many hollow blocks can the Yixin Machinery QT12-15 produce per hour?

The QT12-15 can produce 2376 hollow blocks per hour, ensuring high productivity for your pavement block making needs. |

|---|