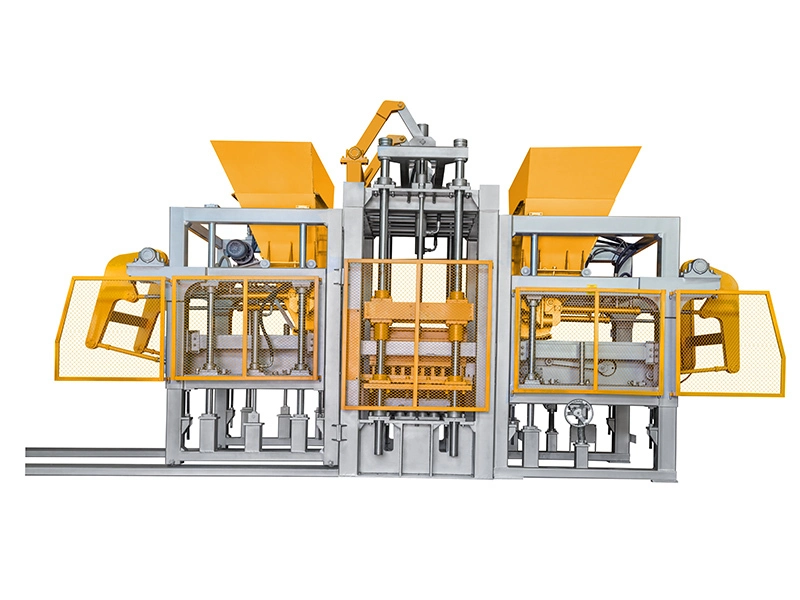

Yixin Machinery Quality Wholesale Fully Set Hydraulic More Durable Heavy Duty Cement Block Making Machine QT15-15

Place of Origin: China

Minimum order quantity: 1set

Color: Blue and yellow can be customzied

Material Science: Q235 Steel ,handox steel

Packing: Film

Delivery time: 25 working days

Model: QT15-15 Heavy Duty

Transaction mode: TT or 100%LC

Discharge port: Xiamen port

TECH DATA

|

The flexible feeding arm on the Yixin QT15-15 block making machine is a key component designed for enhanced stability and efficiency. Its primary function is to automatically and precisely push the material cart into position for each production cycle. This action ensures a consistent and uniform supply of raw concrete mix to the molding system. By replacing manual or less rigid methods, the arm guarantees a smoother, more stable transfer process, which minimizes material spillage and vibration. This results in a more reliable operation, reduces potential downtime, and contributes to the production of higher quality, consistently formed cement blocks. The robust hydraulic-driven design ensures long-term durability and dependable performance under heavy-duty use.

The pressure meter on the Yixin QT15-15 block making machine is a critical gauge for monitoring and adjusting the airbag pressure within the hydraulic system. Proper adjustment of this pressure is essential for controlling the molding force applied to the concrete. By ensuring the airbag pressure is set according to the specific material recipe and block density requirements, the machine achieves optimal compaction. This precise control directly contributes to producing high-quality, consistently dense blocks while also protecting the machine's components from excessive strain, thereby enhancing the overall durability and reliability of the equipment.

The QT15-15 block making machine incorporates a specialized dual-vibration system, consisting of dynamic and static tables. A key feature is the precise 3 mm height difference, where the static table is set lower than the dynamic one. This configuration ensures that bricks are formed through a powerful beating action during the compaction process. This method significantly enhances the density and structural integrity of the finished bricks. As a result, the machine is exceptionally well-suited for producing high-quality colored bricks and taller brick units, where superior surface finish and material consistency are critical requirements. The process guarantees a durable, high-grade product.

|

|---|

|

Product Classification Description : Yixin Machinery Quality Wholesale Fully Set Hydraulic More Durable Heavy Duty Cement Block Making Machine QT15-15 Refer to : The QT15-15 from Yixin Machinery is a fully automatic, heavy-duty block making machine engineered for large-scale industrial production. Its primary application is in the manufacturing of high-strength sand blocks, pavers, and other concrete products for major construction projects, including urban infrastructure, commercial buildings, and residential developments. The machine's customizable molds allow for the production of various shapes and sizes to meet specific architectural requirements. With its high automation and output capacity, it is ideally suited for dedicated factory settings and export-oriented operations that demand consistent quality, efficiency, and mass production of premium construction materials with minimal manual intervention.

|

|---|

|

1.How long does it take to make a block with the Yixin Machinery Quality Wholesale Fully Set Hydraulic More Durable Heavy Duty Cement Block Making Machine QT15-15 ? With a cycle time of 13-25 seconds, this heavy-duty multi-function machine can produce a high volume of blocks efficiently and quickly. 2.How many solid blocks can the Yixin Machinery Quality Wholesale Fully Set Hydraulic More Durable Heavy Duty Cement Block Making Machine QT15-15 produce per hour? This high-performance machine can produce an impressive 20625 solid blocks per hour, making it a highly efficient and productive option for block making. |

|---|

|

|

|---|