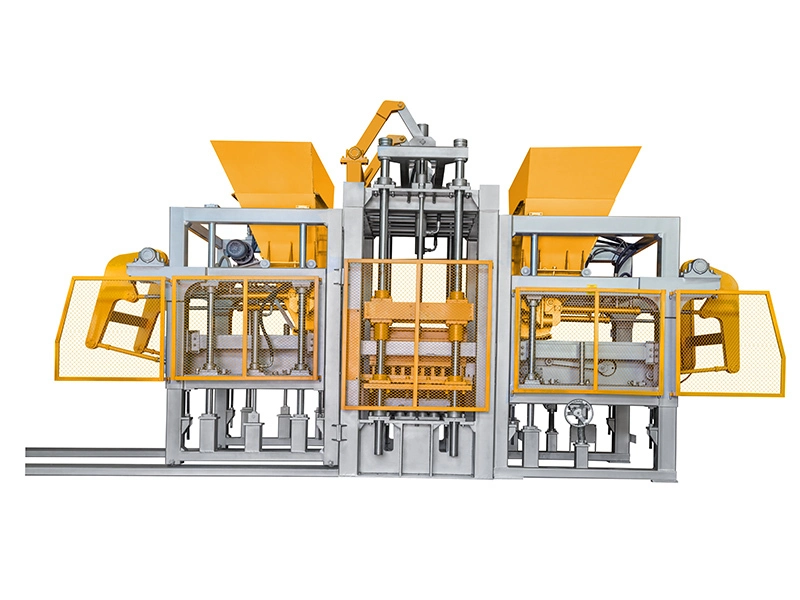

Yixin Machinery Quality Wholesale Premium Hydraulic Heavy Duty Multifunctional Cement Block Making Machine QT15-15

Place of Origin: China

Minimum order quantity: 1set

Color: Blue and yellow can be customzied

Material Science: Q235 Steel ,handox steel

Packing: Film

Delivery time: 25 working days

Model: QT15-15 Heavy Duty

Transaction mode: TT or 100%LC

Discharge port: Xiamen port

TECH DATA

|

The pressure meter of the Yixin Machinery QT15-15 Hydraulic Block Making Machine ensures precise pressure monitoring for optimal performance. It features a durable, high-visibility dial with clear gradations for accurate readings. The meter is designed to withstand heavy-duty use, providing reliable feedback on hydraulic system pressure. Its corrosion-resistant construction ensures longevity in harsh working environments. The device helps maintain consistent block density by allowing real-time pressure adjustments. Easy to install and maintain, it supports efficient operation of the machine. Compatible with standard hydraulic systems, it ensures safety and performance stability during prolonged use.

The QT15-15 cement block making machine from Yixin Machinery features a 90mm diameter guide cylinder and 400mm height bushing, ensuring stable synchronization during the up and down movement of the tamper head and mold frame. This design enhances precision and durability, making it ideal for heavy-duty block production. The machine delivers high efficiency, consistent performance, and reliable operation for large-scale construction projects. Its robust structure and advanced hydraulic system guarantee long-term productivity with minimal maintenance. Perfect for producing premium-quality cement blocks, it is a cost-effective solution for industrial applications.

The Automatic Pallet Provider for the Yixin QT15-15 Cement Block Making Machine ensures seamless operation by efficiently supplying pallets to the production line. It features a robust design for heavy-duty use, compatible with standard pallet sizes. The system enhances productivity by reducing manual handling and minimizing downtime. Its automated mechanism ensures precise pallet placement, improving block formation consistency. Built for durability, it operates smoothly under high-frequency production demands. The user-friendly interface allows easy adjustments and maintenance. This component is essential for achieving high output in hydraulic block manufacturing, ensuring reliability and efficiency in large-scale operations.

|

|---|

|

Product Classification Description : Yixin Machinery Quality Wholesale Premium Hydraulic Heavy Duty Multifunctional Cement Block Making Machine QT15-15 Refer to : The QT15-15 hydraulic heavy-duty multifunctional cement block making machine by Yixin Machinery is ideal for large-scale construction projects, producing high-quality cement blocks efficiently. Suitable for factories, industrial zones, and urban development sites, it ensures durability and precision. Its automated operation reduces labor costs while maintaining consistent output. Perfect for producing pavers, hollow blocks, and solid bricks, it meets diverse construction needs. With robust performance and low maintenance, it is a reliable choice for contractors and manufacturers aiming for productivity and cost-effectiveness in block production.

|

|---|

|

1.How long does it take to make a block with the Yixin Machinery Quality Wholesale Premium Hydraulic Heavy Duty Multifunctional Cement Block Making Machine QT15-15 ? With a cycle time of 13-25 seconds, this heavy-duty multi-function machine can produce a high volume of blocks efficiently and quickly. 2.How many solid blocks can the Yixin Machinery Quality Wholesale Premium Hydraulic Heavy Duty Multifunctional Cement Block Making Machine QT15-15 produce per hour? This high-performance machine can produce an impressive 20625 solid blocks per hour, making it a highly efficient and productive option for block making. |

|---|

|

1.Adopting the best international design process, advanced technology. 2.Crank arm fabrication, fast and uniform. 3.Guide column dynamic demoulding mechanism, demoulding parallel and more accurate. 4.Suspended material cart, fabrication faster and more durable. 5.The vibration box adopts a variety of linkage vibrations, with a large molding area and high product density. 6.Servo frequency modulation drive control can be selected, with fast vibration start, short molding cycle and more accurate control. 7.Optional intelligent remote control electronic control can grasp the equipment operation status in real time, remotely control, operate, judge and solve equipment failures; online monitoring of the equipment operation status, online prediction and diagnosis of the equipment application operation and status. |

|---|