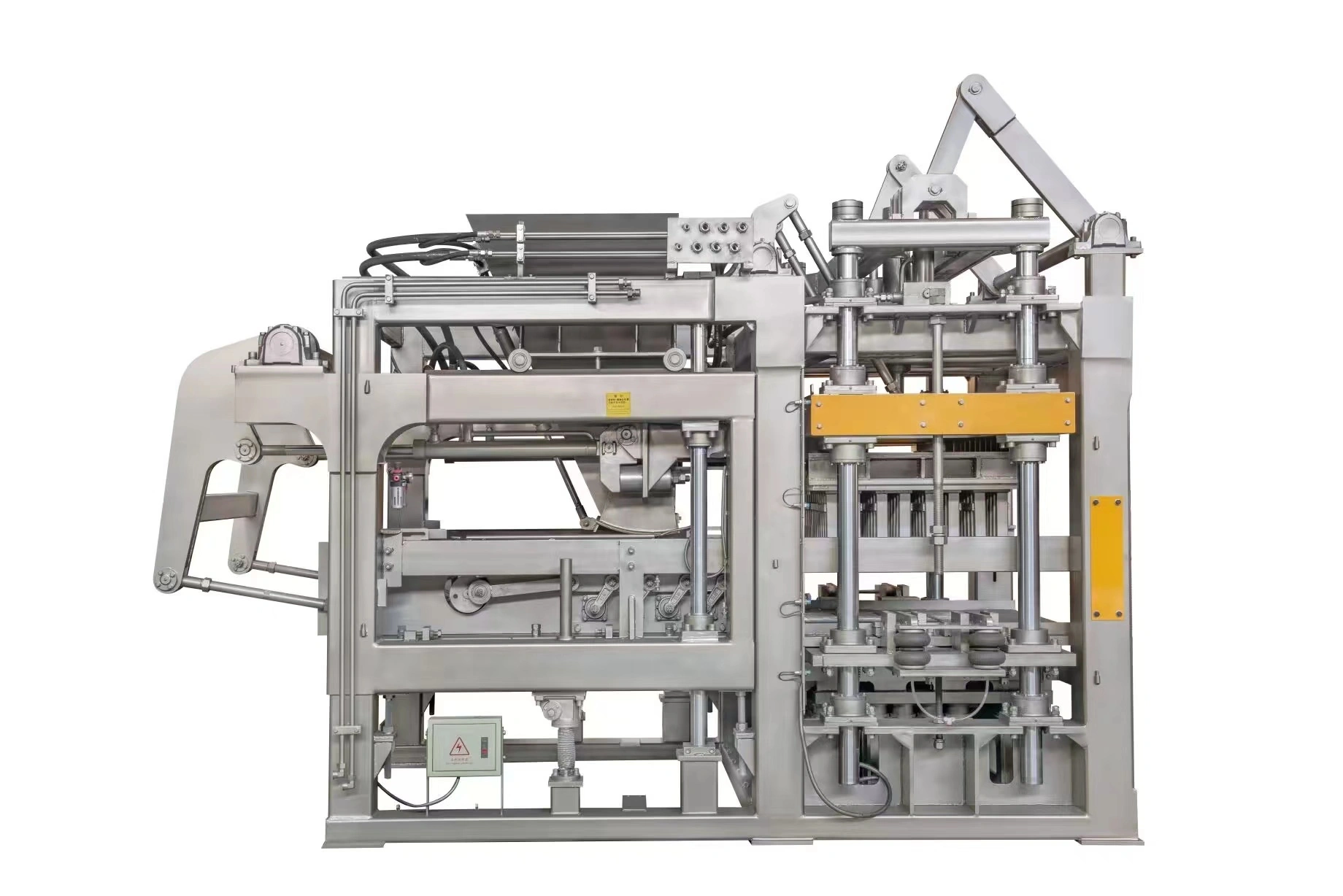

Yixin Machinery Satisfaction Guarantee High Standard More Robust Heavy Duty Hollow Block Making Machine QT10-15

Place of Origin: China

Minimum order quantity: 1set

Color: Blue and yellow can be customzied

Material Science: Q235 Steel ,handox steel

Packing: Film

Delivery time: 25 working days

Model: QT10-15 heavy duty

Transaction mode: TT or 100%LC

Discharge port: Xiamen port

Tech Data

|

The flexible feeding arm on the Yixin QT10-15 Heavy Duty Hollow Block Making Machine is a key component engineered for precision and reliability. Its primary function is to ensure a consistent, even, and rapid distribution of raw concrete mix into the mold cavities. This precise feeding action is crucial for producing high-density blocks with uniform structural integrity and superior surface finish. The arm's flexible design allows it to adapt smoothly to the mold box, minimizing material segregation and waste. By optimizing the filling process, it directly contributes to the machine's high output efficiency, stable production rhythm, and the overall robustness of the final QT10-15 blocks, fully supporting the promised high-standard performance and satisfaction guarantee.

The dynamic and static vibration table of the Yixin QT10-15 Heavy Duty Hollow Block Making Machine is a core component engineered for superior performance. It ensures optimal compaction of concrete mix within the molds through a combination of dynamic vibration during the filling phase and high-frequency static pressure vibration during the final compression. This dual-action system effectively eliminates air pockets, resulting in blocks with extremely high density, uniform structural integrity, and excellent surface finish. Designed for robustness, the system guarantees consistent product quality, enhanced production efficiency, and reliable, long-term operation even under continuous, high-output working conditions.

The demolding synchronize function of the Yixin QT10-15 Heavy Duty Hollow Block Making Machine represents a core technological advancement, ensuring optimal performance and product integrity. This system precisely coordinates the demolding process, where the freshly formed blocks are released from the molds. The synchronized movement guarantees perfectly vertical and balanced ejection, which is critical for maintaining the dimensional accuracy and sharp edges of the large QT10-15 blocks. It eliminates stress concentrations during demolding, drastically reducing the risk of product damage or deformation. This robust synchronization enhances overall operational smoothness, minimizes cycle time, and contributes significantly to the machine's legendary durability and consistent, high-quality output, fully supporting our high-standard satisfaction guarantee.

|

|---|

|

Product Classification Description: Yixin Machinery Satisfaction Guarantee High Standard More Robust Heavy Duty Hollow Block Making Machine QT10-15 Refer to : The QT10-15 Heavy Duty Hollow Block Making Machine is engineered for large-scale production in robust construction and infrastructure projects. Its high-capacity, fully automated system is ideal for manufacturing standard and customized hollow blocks, pavers, curbstones, and other precast concrete elements at an industrial volume. The machine's exceptional durability and stability ensure continuous, reliable operation in demanding environments, such as dedicated block manufacturing plants, major urban development sites, and heavy-duty municipal works. Yixin's Satisfaction Guarantee underscores its commitment to delivering consistent output quality, minimal downtime, and long-term performance, making the QT10-15 a cornerstone asset for builders and contractors seeking productivity and strength for high-output requirements.

|

|---|

|

1.How many days to change vibration box oil ,what kind of oil can be used inside?

The hydraulic oil 68 degree can be used, the amount is from bottom 3cm. Strongly suggest 1 month change one time oil 2. How many hollow blocks can the Yixin Machinery QT10-15 produce per hour?

The QT10-15 can produce 1980 hollow blocks per hour, ensuring high productivity for your pavement block making needs. |

|---|