The Ultimate Guide To Choosing A Concrete Block Making Machine

Are you considering investing in a concrete block making machine but unsure of where to start? Look no further - our Ultimate Guide to Choosing a Concrete Block Making Machine has got you covered! Whether you're a seasoned professional or a newcomer to the industry, this comprehensive guide will provide you with everything you need to know to make an informed decision. From different types of machines to key features to consider, we've got all the information you need to find the perfect concrete block making machine for your needs. Let's dive in and revolutionize your business today!

- Understanding the Different Types of Concrete Block Making Machines

Concrete block making machines play a crucial role in the construction industry as they are used to produce blocks that are essential for building structures. In order to choose the right machine for your needs, it is important to understand the different types of concrete block making machines available on the market.

The first type of concrete block making machine is the manual machine. This machine requires human labor to operate and is typically used for small-scale production. Manual machines are affordable and simple to use, making them ideal for those who are just starting out in the block-making business.

The second type of concrete block making machine is the semi-automatic machine. This machine combines the benefits of manual and fully automatic machines, as it requires some manual labor but also has automated features. Semi-automatic machines are suitable for medium-sized production and offer a good balance between cost and efficiency.

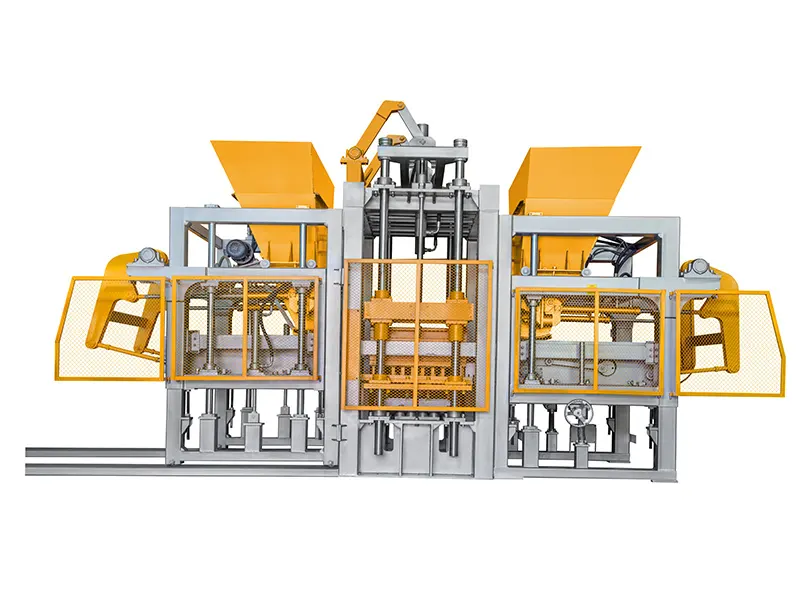

The third type of concrete block making machine is the fully automatic machine. These machines are equipped with advanced technology and can produce a large number of blocks in a short amount of time. Fully automatic machines are ideal for high-volume production and are often used by large construction companies.

In addition to the different types of machines, there are also various sizes and configurations available. Some machines are designed to produce specific types of blocks such as hollow, solid, or interlocking blocks. It is important to choose a machine that is compatible with the type of blocks you want to produce.

When selecting a concrete block making machine, it is important to consider factors such as production capacity, efficiency, and cost. It is also important to ensure that the machine is durable and easy to maintain. By understanding the different types of machines available, you can make an informed decision and choose the right machine for your specific needs.

In conclusion, choosing a concrete block making machine requires careful consideration of the different types and features available. Whether you are looking for a manual, semi-automatic, or fully automatic machine, it is important to choose a machine that meets your production requirements and budget. By selecting the right machine, you can streamline your production process and increase the efficiency of your block-making business.

- Factors to Consider When Choosing a Concrete Block Making Machine

When selecting a concrete block making machine for your construction project, there are several key factors to consider in order to make the best choice. Whether you are a seasoned professional or a newcomer to the industry, it is crucial to take into account these important aspects before making a purchase. In this ultimate guide, we will walk you through the factors to consider when choosing a concrete block making machine.

1. Production capacity: One of the most important factors to consider when selecting a concrete block making machine is its production capacity. You need to determine how many blocks you need to produce per day in order to meet your project requirements. Make sure to choose a machine that can handle the desired output without compromising on quality.

2. Automation level: Another key factor to consider is the level of automation of the machine. Some machines are fully automated, while others require more manual intervention. Depending on your project needs and budget, you can choose a machine that offers the right balance of automation and manual control.

3. Size and weight of blocks: Different concrete block making machines can produce blocks of varying sizes and weights. It is important to have a clear idea of the size and weight specifications of the blocks you need for your project in order to select the right machine that can meet these requirements.

4. Quality of blocks: The quality of the blocks produced by the machine is another crucial factor to consider. Make sure to choose a machine that can produce high-quality and durable blocks that meet industry standards. You can look for machines that have a reputation for producing consistent and reliable results.

5. Maintenance and support: When choosing a concrete block making machine, it is important to consider the maintenance requirements and the availability of support services. Look for machines that are easy to maintain and have a reliable customer support system in place in case of any issues or breakdowns.

6. Energy efficiency: Energy efficiency is an important factor to consider when selecting a concrete block making machine. Choose a machine that is energy-efficient and can help you save on operational costs in the long run. This will not only benefit your budget but also contribute to a more sustainable construction process.

7. Budget: Finally, it is essential to consider your budget when choosing a concrete block making machine. There are machines available at different price points, so make sure to find one that fits within your budget while meeting all your project requirements.

In conclusion, selecting the right concrete block making machine is a critical decision that can have a significant impact on the success of your construction project. By considering factors such as production capacity, automation level, block size and weight, quality, maintenance, energy efficiency, and budget, you can make an informed choice that will help you achieve your project goals efficiently and effectively.

- Evaluating the Capacity and Output of Concrete Block Making Machines

When it comes to selecting a concrete block making machine, one of the most crucial aspects to consider is evaluating its capacity and output. Understanding these factors will not only help you make an informed decision but also ensure that your production needs are met effectively.

Capacity refers to the volume of blocks that a machine can produce in a given time frame. This is typically measured in terms of blocks per hour or blocks per day. It is important to assess your production requirements and choose a machine that can meet or exceed your output goals.

Different concrete block making machines come with varying capacities, ranging from a few hundred to several thousand blocks per hour. Factors that can affect capacity include the size and design of the machine, the type of blocks being produced, and the speed at which the machine operates.

For small-scale operations or start-up businesses, a machine with a lower capacity may be sufficient. However, for larger projects or industrial-scale production, a high-capacity machine will be essential to meet demand and maximize efficiency.

Output, on the other hand, refers to the quality and consistency of the blocks produced by the machine. Factors that can impact output include the quality of raw materials, the precision of the machine's mechanisms, and the skill of operators.

To evaluate the output of a concrete block making machine, it is important to consider the size, shape, and strength of the blocks it produces. The machine should be able to consistently create blocks that meet industry standards and customer expectations.

Additionally, factors such as maintenance requirements, energy efficiency, and ease of operation can also impact the overall output of the machine. Choosing a machine that is durable, reliable, and easy to maintain will help ensure consistent and high-quality block production.

In conclusion, when selecting a concrete block making machine, it is crucial to evaluate both the capacity and output of the machine. By considering factors such as production goals, block quality, and operational efficiency, you can choose a machine that will meet your needs and deliver optimal results. Remember to thoroughly research and compare different machines before making a decision to ensure that you invest in the right equipment for your business.

- Comparing Prices and Quality of Concrete Block Making Machines

When it comes to choosing a concrete block making machine, it is essential to consider both the prices and the quality of the machines available in the market. In this ultimate guide, we will delve into the key factors to consider when selecting a concrete block making machine, with a particular focus on comparing prices and quality.

Price is often a significant consideration when purchasing a concrete block making machine. The cost of the machine can vary greatly depending on factors such as the brand, model, capacity, and features. It is essential to set a budget and compare prices from various manufacturers to ensure you are getting the best value for your money. Additionally, it is crucial to consider any additional costs, such as maintenance, repairs, and operating expenses, when calculating the overall cost of the machine.

While price is an important factor, it should not be the only consideration when choosing a concrete block making machine. The quality of the machine is equally important, as it will impact the durability, performance, and efficiency of your block production process. When comparing the quality of different machines, consider factors such as the construction materials used, the reputation of the manufacturer, and the machine's reliability and durability.

Another key aspect to consider when choosing a concrete block making machine is the production capacity. The machine's capacity will determine how many blocks it can produce in a given time frame, which is crucial for meeting the demands of your business or project. Additionally, consider the size and shape of the blocks the machine can produce, as well as any customization options available to suit your specific requirements.

When comparing prices and quality of concrete block making machines, it is also essential to consider the level of support and service provided by the manufacturer. Look for a reputable manufacturer that offers warranties, technical support, and training to ensure you can effectively operate and maintain your machine. Additionally, seek out customer reviews and testimonials to gauge the overall satisfaction and experience of other users with the manufacturer and their machines.

In conclusion, choosing the right concrete block making machine requires a careful consideration of both the prices and quality of the machines available. By comparing prices, quality, production capacity, and manufacturer support, you can make an informed decision that meets your budget and production needs. Remember that investing in a high-quality machine may cost more initially but can lead to long-term savings and increased efficiency in the long run. Choose wisely to ensure the success of your concrete block production business or project.

- Tips for Maintaining and Maximizing the Efficiency of Your Concrete Block Making Machine

The Ultimate Guide to Choosing a Concrete Block Making Machine - Tips for Maintaining and Maximizing Efficiency

When it comes to selecting a concrete block making machine for your construction projects, there are a few key factors to consider in order to ensure you are getting the right equipment for the job. From the type of machine to the size and capacity, making an informed decision can make all the difference in the efficiency and productivity of your operations.

First and foremost, it is essential to choose a machine that is suitable for the type of concrete blocks you plan to produce. There are various types of machines available on the market, including manual, automatic, and semi-automatic models. Manual machines require more labor and time to operate, while automatic machines offer higher efficiency and output but come with a higher price tag. Consider your budget and production needs when deciding which type of machine is best for your business.

In addition to the type of machine, size and capacity are also important factors to consider. Larger machines have higher production capacities but also come with a larger footprint and higher operating costs. Assess your current and future production needs to determine the appropriate size and capacity for your concrete block making machine.

Once you have selected the right machine for your needs, it is crucial to properly maintain and care for it in order to maximize its efficiency and lifespan. Regular inspections and maintenance checks should be conducted to ensure that all components are in good working condition. Lubricate moving parts, replace worn-out components, and clean the machine regularly to prevent breakdowns and ensure smooth operation.

It is also important to follow the manufacturer's guidelines for operating the machine and producing concrete blocks. Pay attention to factors such as mix design, curing time, and temperature to ensure the quality and strength of the blocks. Properly calibrated molds and a consistent production process are key to producing high-quality concrete blocks efficiently.

In conclusion, choosing the right concrete block making machine is essential for the success of your construction projects. By considering factors such as type, size, and capacity, as well as maintaining and caring for the machine properly, you can maximize its efficiency and productivity. With the right equipment and proper maintenance, you can ensure that your concrete block making machine continues to meet your production needs for years to come.

Conclusion

In conclusion, after exploring the ins and outs of choosing a concrete block making machine in this ultimate guide, it is clear that the key to selecting the perfect machine lies in considering your specific needs, budget, and production requirements. With 18 years of experience in the industry, our company understands the importance of investing in a high-quality machine that will deliver consistent results and help you grow your business. By following the tips and recommendations outlined in this guide, you can confidently choose a concrete block making machine that meets your needs and sets you up for success in the industry. Remember, the right machine can make all the difference in the efficiency and profitability of your concrete block production process.