The Ultimate Guide To Choosing The Best Concrete Block Making Machine

Are you in the market for a new concrete block making machine but feeling overwhelmed by the multitude of options available? Look no further! In this comprehensive guide, we will provide you with everything you need to know to choose the best concrete block making machine for your specific needs. From different types of machines to key considerations when making your decision, we've got you covered. Read on to discover how you can make the most informed choice and take your concrete block production to the next level.

- Understanding the Different Types of Concrete Block Making Machines

When it comes to choosing a concrete block making machine, there are many factors to consider. Understanding the different types of machines available is essential to making the best decision for your specific needs. In this comprehensive guide, we will explore the various types of concrete block making machines, their features, and benefits to help you make an informed choice.

1. Manual Concrete Block Making Machines:

Manual concrete block making machines are the most basic and simplest form of block making machines. These machines require manual operation to produce concrete blocks. They are typically used for smaller projects or in areas where electricity is not readily available. Manual machines are affordable and easy to operate, making them a popular choice for small-scale block production.

2. Semi-Automatic Concrete Block Making Machines:

Semi-automatic concrete block making machines are a step up from manual machines. These machines require some manual intervention but also have automated features that make the block production process more efficient. They are suitable for medium-sized projects and offer a good balance between manual labor and automation.

3. Fully Automatic Concrete Block Making Machines:

Fully automatic concrete block making machines are the most advanced and efficient type of machines available. These machines are fully automated, requiring minimal human intervention. They have a high production capacity and can produce large quantities of concrete blocks in a short period of time. Fully automatic machines are ideal for large-scale projects and commercial applications.

4. Mobile Concrete Block Making Machines:

Mobile concrete block making machines are designed for on-site block production. These machines are mounted on wheels, making them easy to transport to different locations. They are ideal for construction projects that require blocks to be produced on-site, eliminating the need for transportation of blocks from a centralized location.

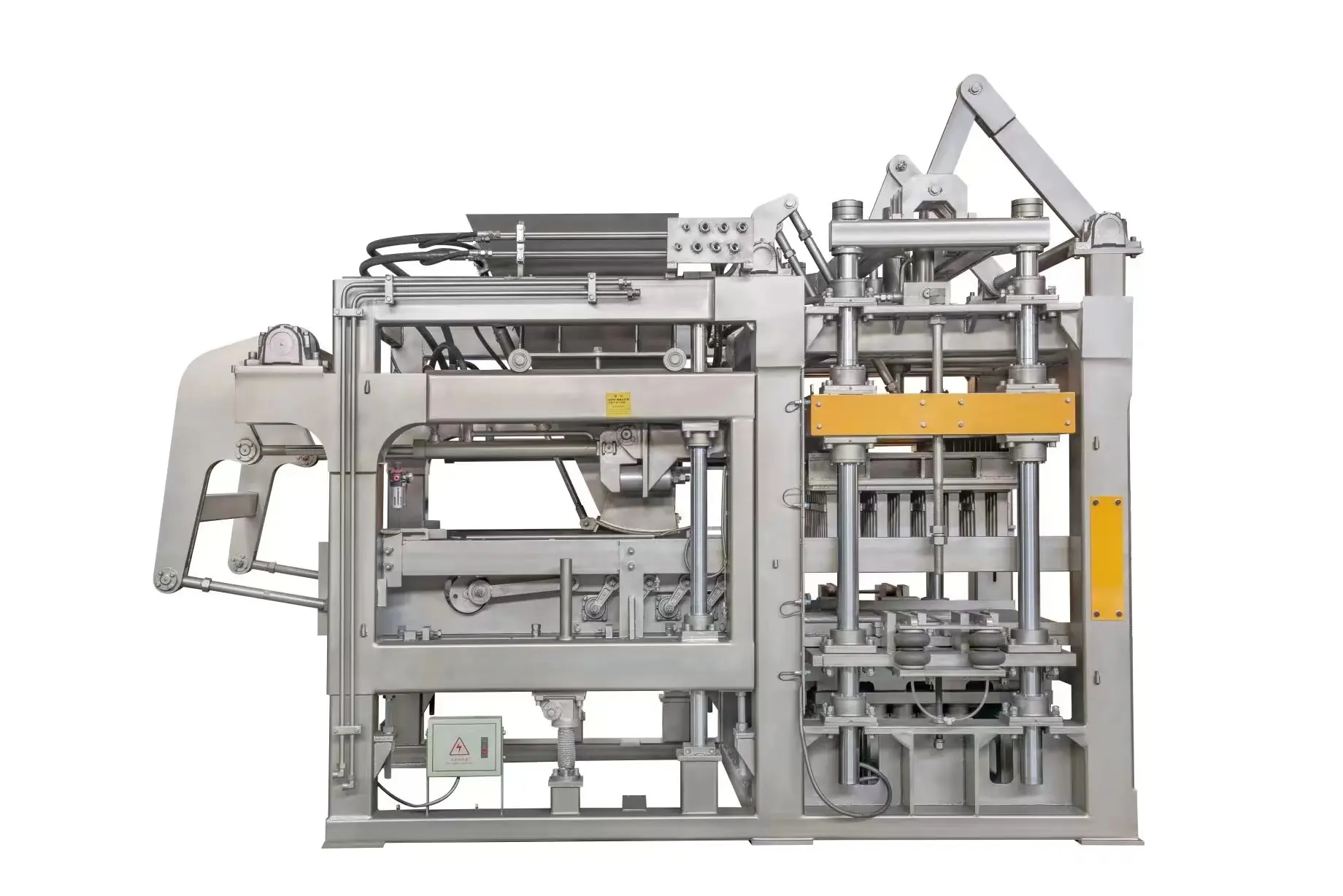

5. Hydraulic Concrete Block Making Machines:

Hydraulic concrete block making machines use hydraulic pressure to compress the concrete mixture into blocks. These machines are known for their high compression force, resulting in strong and durable concrete blocks. They are ideal for producing high-quality blocks for construction projects that require strength and durability.

In conclusion, choosing the best concrete block making machine depends on the specific requirements of your project. Consider factors such as production capacity, automation level, mobility, and block quality when selecting a machine. By understanding the different types of machines available, you can make an informed decision to ensure the success of your block production project.

- Factors to Consider When Choosing a Concrete Block Making Machine

When it comes to choosing a concrete block making machine, there are several important factors to consider in order to ensure that you are selecting the best option for your needs. Whether you are in the construction industry or simply looking to make concrete blocks for a DIY project, taking the time to evaluate these factors will help you make an informed decision.

One of the most important factors to consider when choosing a concrete block making machine is the production capacity. It is crucial to determine how many blocks you need to produce on a daily basis in order to ensure that the machine you select can meet your production requirements. Consider factors such as the size of your project, your available space, and your budget when determining the ideal production capacity for your needs.

Another key factor to consider is the type of concrete blocks you wish to produce. Different machines are capable of producing different types of blocks, such as solid blocks, hollow blocks, interlocking blocks, and paving blocks. Consider the specific requirements of your project and choose a machine that is capable of producing the type of blocks you need.

Additionally, it is important to consider the power source of the machine. Some machines are powered by electricity, while others may be powered by diesel or gasoline. Consider factors such as availability of power sources in your area, operating costs, and environmental impact when choosing a machine with the appropriate power source for your needs.

It is also important to consider the size and weight of the machine. Ensure that the machine you choose can easily be transported to your project site and fits within the available space. Consider factors such as ease of operation, maintenance requirements, and overall durability when evaluating the size and weight of the machine.

Furthermore, consider the reputation of the manufacturer when choosing a concrete block making machine. Research different manufacturers, read reviews, and ask for recommendations from colleagues or industry experts. Choosing a machine from a reputable manufacturer will ensure that you are investing in a high-quality, reliable product.

In conclusion, the process of choosing a concrete block making machine involves evaluating factors such as production capacity, type of blocks, power source, size and weight, and manufacturer reputation. By taking the time to carefully consider these factors, you can select the best machine for your needs and ensure the success of your concrete block production project.

- Evaluating the Production Capacity and Efficiency of Concrete Block Making Machines

Concrete block making machines are essential equipment in the construction industry, helping to produce the building blocks that form the foundation of many structures. However, not all machines are created equal, and evaluating their production capacity and efficiency is crucial in choosing the best one for your needs.

Production capacity refers to the amount of blocks a machine can produce in a given time period. This is an important factor to consider, especially for commercial operations where large quantities of blocks are needed. Machines with higher production capacities can help increase efficiency and reduce production times, ultimately leading to cost savings and increased profitability.

Efficiency, on the other hand, refers to how well a machine utilizes its resources to produce blocks. This includes factors such as energy consumption, maintenance requirements, and overall performance. A more efficient machine will not only save on operational costs but also ensure consistent quality in the blocks produced.

When evaluating the production capacity and efficiency of concrete block making machines, there are several key factors to consider. Firstly, the type of machine plays a significant role in determining its capabilities. There are different types of concrete block making machines, including manual, semi-automatic, and fully automatic models, each with varying levels of production capacity and efficiency.

Manual machines are suitable for small-scale operations and have lower production capacities compared to semi-automatic and fully automatic machines. Semi-automatic machines require some manual intervention but can produce a higher volume of blocks, while fully automatic machines are the most efficient and can produce blocks at a much faster rate.

Another important factor to consider is the size and shape of the blocks that the machine is capable of producing. Different machines have varying capabilities in terms of block size and shape, so it is essential to choose a machine that can meet your specific requirements.

Furthermore, the quality of materials used in the construction of the machine can also impact its production capacity and efficiency. Machines made with high-quality materials are more durable and have a longer lifespan, reducing the need for frequent maintenance and repairs.

In conclusion, when choosing the best concrete block making machine, it is crucial to evaluate its production capacity and efficiency. Considering factors such as the type of machine, block size and shape capabilities, and the quality of materials used can help you make an informed decision and select a machine that meets your needs. By investing in a machine with high production capacity and efficiency, you can ensure optimal performance and maximize the productivity of your construction operations.

- Exploring the Features and Technology of Modern Concrete Block Making Machines

When it comes to building materials, concrete blocks are a popular choice due to their durability and versatility. However, traditional methods of making concrete blocks can be time-consuming and labor-intensive. That's where modern concrete block making machines come in. These machines are designed to streamline the block-making process, making it faster, easier, and more efficient than ever before.

In this comprehensive guide, we will take a closer look at the features and technology of modern concrete block making machines to help you choose the best one for your needs. From automatic to semi-automatic machines, there are a variety of options available on the market today. Understanding the different features and technologies of these machines will help you make an informed decision when selecting the right one for your construction projects.

One of the key features to consider when choosing a concrete block making machine is its production capacity. Machines come in a range of capacities, from small-scale machines suitable for small construction projects to large-scale machines capable of producing thousands of blocks per day. Understanding your production needs will help you determine the right capacity for your machine.

Another important feature to consider is the level of automation of the machine. Automatic machines are equipped with advanced technology that allows them to operate with minimal human intervention, while semi-automatic machines require more manual labor. The level of automation will impact the efficiency and speed of the block-making process, so it's important to choose a machine that aligns with your production goals.

In addition to production capacity and automation, it's also important to consider the technology used in the machine. Modern concrete block making machines are equipped with cutting-edge technology that allows for precise block formation, consistent quality, and reduced waste. Features such as vibration technology, hydraulic systems, and computerized control panels all play a role in the efficiency and performance of the machine.

When choosing a concrete block making machine, it's essential to consider not only the features and technology of the machine but also the reputation of the manufacturer. Look for a reputable manufacturer with a track record of producing high-quality, reliable machines. Reading reviews and talking to other customers can provide valuable insights into the performance and reliability of the machine.

In conclusion, a concrete block making machine is a valuable investment for any construction project. By understanding the features and technology of modern machines, you can choose the best one for your production needs. From production capacity to automation to technology, there are a variety of factors to consider when selecting a machine. By doing your research and choosing a reputable manufacturer, you can ensure that you are investing in a machine that will streamline your block-making process and deliver high-quality results.

- Comparing Prices and Finding the Best Value for a Concrete Block Making Machine

When it comes to investing in a concrete block making machine, it is crucial to consider various factors in order to ensure that you are getting the best value for your money. In this ultimate guide, we will walk you through the process of comparing prices and finding the right concrete block making machine for your needs.

First and foremost, it is important to understand the key features and specifications of a concrete block making machine. These machines are used to produce concrete blocks of various sizes and shapes for construction purposes. They typically consist of a mold box, a hydraulic system, and a vibration system. The capacity of the machine, the type of blocks it can produce, and its overall efficiency are all important factors to consider when choosing the right machine for your project.

One of the most important aspects to consider when choosing a concrete block making machine is the price. Prices can vary significantly depending on the size and capacity of the machine, as well as the brand and quality of the materials used. It is important to compare prices from different suppliers and manufacturers in order to find the best value for your money. While it may be tempting to opt for the cheapest option available, it is important to keep in mind that quality should not be compromised for the sake of saving a few dollars.

In addition to price, it is also important to consider the reputation and reliability of the supplier or manufacturer. Look for reviews and testimonials from other customers to get an idea of the quality of their products and customer service. It is also a good idea to ask for references and visit their production facilities if possible. A reputable supplier will be transparent about their manufacturing process and will be more than willing to provide you with all the information you need to make an informed decision.

Another important factor to consider when choosing a concrete block making machine is the after-sales service and support provided by the supplier. Look for a supplier that offers a comprehensive warranty and maintenance plan, as well as technical support and training for your operators. It is also important to consider the availability of spare parts and service technicians in case of any issues or repairs that may be needed.

In conclusion, choosing the best concrete block making machine requires careful consideration of various factors such as price, quality, reputation, and after-sales support. By comparing prices and doing thorough research, you can ensure that you are getting the best value for your money and that your investment will be a long-lasting and profitable one.

Conclusion

In conclusion, choosing the best concrete block making machine is a crucial decision for any business in the construction industry. With 18 years of experience, our company understands the importance of quality, efficiency, and reliability when it comes to selecting the right machine for your needs. By following the ultimate guide provided in this article, you can make an informed decision that will ultimately lead to success and growth for your business. Trust in our expertise and experience to help you find the perfect concrete block making machine for your projects. Reach out to us today and let us help you take your business to the next level.