The Advantages Of Investing In A Cement Block Making Machine

Are you considering investing in a cement block making machine but unsure of the benefits it can bring to your business? Look no further! In this article, we will explore the numerous advantages that come with investing in a cement block making machine. From increased production efficiency to cost savings, the benefits are endless. Read on to discover how this investment can revolutionize your operations and take your business to the next level.

- Increased Productivity and Efficiency

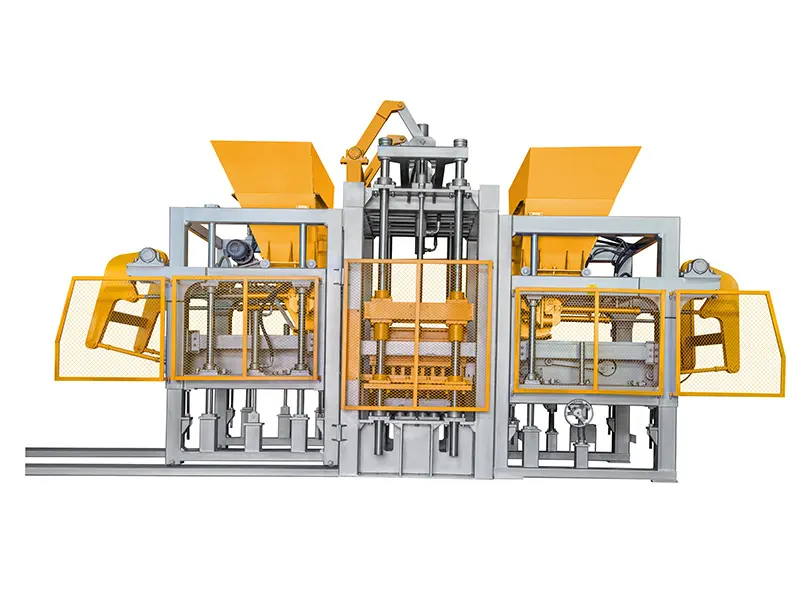

In today's rapidly evolving construction industry, investing in a cement block making machine is crucial for companies looking to increase productivity and efficiency. These machines are designed to produce high-quality cement blocks in a fraction of the time it would take to do so manually. With advancements in technology, these machines have become more sophisticated and automated, offering a wide range of benefits for construction companies.

One of the key advantages of investing in a cement block making machine is the increased productivity it offers. These machines are capable of producing a large number of cement blocks in a short amount of time, allowing construction companies to meet tight deadlines and take on more projects. This increased productivity not only boosts profits but also enhances the company's reputation for delivering high-quality work in a timely manner.

Furthermore, cement block making machines are highly efficient, reducing the amount of manual labor required to produce cement blocks. This not only saves time but also minimizes the risk of human error, resulting in consistently uniform and durable cement blocks. By automating the production process, construction companies can streamline their operations and allocate their workforce to other tasks, increasing overall efficiency and reducing costs.

Another advantage of investing in a cement block making machine is the flexibility it offers in terms of customization. These machines can be easily adjusted to produce different sizes and shapes of cement blocks, giving construction companies the ability to meet the specific requirements of each project. This adaptability allows companies to diversify their product offerings and cater to a wider range of clients, ultimately increasing their market share and competitiveness in the industry.

Additionally, investing in a cement block making machine can lead to long-term cost savings for construction companies. While the initial investment may seem substantial, the savings in labor costs, material waste, and operational expenses over time can outweigh the upfront cost. By consistently producing high-quality cement blocks with minimal waste, companies can improve their bottom line and achieve a higher return on investment in the long run.

In conclusion, investing in a cement block making machine is a strategic decision for construction companies looking to improve productivity and efficiency. These machines offer a range of benefits, including increased productivity, efficiency, customization, and cost savings. By incorporating a cement block making machine into their operations, construction companies can stay ahead of the competition, deliver high-quality work, and achieve success in the ever-evolving construction industry.

- Cost Savings and Return on Investment

Investing in a cement block making machine can bring about a multitude of benefits for businesses in the construction industry. One of the primary advantages of utilizing this machine is the cost savings and return on investment it can provide. In this article, we will explore the various ways in which investing in a cement block making machine can lead to substantial financial gains for companies.

First and foremost, a cement block making machine allows for the production of high-quality concrete blocks at a significantly lower cost than purchasing pre-made blocks from suppliers. By manufacturing their own blocks on-site, construction companies can eliminate the need to outsource this process, thereby reducing expenses associated with transportation, labor, and overhead. This results in substantial cost savings that can have a direct impact on a company's bottom line.

Furthermore, the efficiency of a cement block making machine enables businesses to increase their production output and meet the demands of larger projects in a timely manner. This increased productivity not only leads to higher revenues but also allows companies to take on more projects and expand their client base. In essence, the investment in a cement block making machine can open up new opportunities for growth and profitability.

Moreover, the durability and longevity of concrete blocks produced by a cement block making machine further contribute to cost savings in the long run. These blocks are known for their strength and resilience, making them ideal for use in a variety of construction projects. By using high-quality blocks produced in-house, businesses can reduce the need for frequent repairs and replacements, ultimately saving money on maintenance costs.

In addition to cost savings, investing in a cement block making machine also offers a lucrative return on investment. The initial upfront cost of purchasing a machine may seem significant, but the long-term benefits far outweigh the initial investment. With proper maintenance and care, a cement block making machine can last for many years, generating profits for the business well into the future.

In conclusion, the advantages of investing in a cement block making machine are clear. From cost savings to a substantial return on investment, this machine offers numerous financial benefits for businesses in the construction industry. By harnessing the efficiency and productivity of a cement block making machine, companies can not only streamline their operations but also enhance their profits and competitiveness in the market. Investing in this technology is a smart decision that can propel businesses towards success and sustainability.

- Diversification of Product Range

Diversification of Product Range

Investing in a cement block making machine can bring a multitude of benefits to any business looking to expand its product range. These machines are versatile and can produce a wide variety of concrete products, ranging from simple bricks to intricate pavers. By diversifying their product range, businesses can cater to a wider range of customers and increase their revenue streams.

One of the biggest advantages of investing in a cement block making machine is the ability to customize products to meet the specific needs of customers. These machines can be easily adjusted to produce different sizes, shapes, and designs, allowing businesses to offer unique and personalized products. This level of customization can give businesses a competitive edge in the market and attract more customers.

Another advantage of diversifying product range with a cement block making machine is the ability to tap into new markets. By offering a wider range of products, businesses can appeal to different customer demographics and expand their customer base. For example, by producing decorative pavers and landscaping stones, businesses can target homeowners looking to enhance their outdoor spaces. By offering sturdy concrete blocks, businesses can attract contractors and construction companies looking for durable building materials.

Additionally, the production process of cement blocks is cost-effective and efficient, making it a lucrative investment for businesses. These machines are designed to operate with minimal manpower, reducing labor costs and increasing productivity. The materials used to make cement blocks are readily available and affordable, further lowering production costs. With a cement block making machine, businesses can increase their profit margins and grow their business.

Furthermore, investing in a cement block making machine can also be environmentally friendly. Concrete is a sustainable building material that is recyclable and energy-efficient. By producing concrete products locally, businesses can reduce carbon emissions associated with transportation and contribute to a more sustainable future. Customers are increasingly looking for eco-friendly products, and offering concrete blocks can attract environmentally conscious consumers.

In conclusion, investing in a cement block making machine can bring a range of benefits to businesses looking to diversify their product range. These machines offer customization, efficiency, cost-effectiveness, and environmental sustainability, making them a valuable asset for any business. By diversifying their product range with concrete products, businesses can expand their customer base, increase revenue, and stay ahead of the competition in the market.

- Quality Control and Consistency

When it comes to investing in a cement block making machine, one of the key advantages that cannot be overlooked is the emphasis on quality control and consistency. These two factors play a crucial role in the production of cement blocks, which are widely used in the construction industry for building walls, pavements, and other structures.

Quality control is essential in ensuring that the cement blocks produced are of the highest standard. With a cement block making machine, manufacturers have the ability to closely monitor the production process and make adjustments as needed to maintain consistent quality. This includes controlling the amount of cement, sand, and water used in each block, as well as monitoring factors such as curing time and temperature. By maintaining strict quality control measures, manufacturers can ensure that each cement block meets the required specifications and will perform reliably in construction projects.

Consistency is another important aspect of investing in a cement block making machine. With the ability to produce large quantities of cement blocks on a regular basis, manufacturers can ensure a consistent supply of building materials to meet the demands of construction projects. This is especially important for larger construction projects that require a large number of cement blocks to be produced within a specific timeframe. By using a cement block making machine, manufacturers can streamline the production process and create a steady flow of high-quality blocks that are uniform in size and shape.

In addition to quality control and consistency, investing in a cement block making machine offers several other advantages. One of the main benefits is increased efficiency and productivity. By automating the production process, manufacturers can significantly reduce labor costs and improve overall efficiency. This not only results in cost savings for the manufacturer but also allows for faster production times, ultimately speeding up construction projects and increasing profitability.

Furthermore, a cement block making machine offers versatility in terms of the types of blocks that can be produced. Manufacturers can customize the machine to produce different sizes and shapes of cement blocks, depending on the specific requirements of a project. This flexibility allows for greater adaptability in meeting the varying needs of different construction projects, from residential buildings to commercial structures.

Overall, investing in a cement block making machine can provide manufacturers with a competitive edge in the construction industry. With a focus on quality control and consistency, as well as increased efficiency and versatility, manufacturers can produce high-quality cement blocks that meet the demands of construction projects while maximizing profitability. It is clear that a cement block making machine is a valuable investment for any manufacturer looking to enhance their production capabilities and stay ahead in a competitive market.

- Environmental sustainability and waste reduction

Cement block making machines have been revolutionizing the construction industry by enabling the production of high-quality and durable cement blocks at a faster rate. In recent years, there has been a growing emphasis on environmental sustainability and waste reduction in the construction sector. Investing in a cement block making machine not only brings numerous benefits to construction companies but also helps promote environmental sustainability and waste reduction.

One of the primary advantages of investing in a cement block making machine is the significant reduction in waste produced during the manufacturing process. Traditional methods of producing cement blocks involve a high level of waste generation due to the manual handling of materials and imprecise cutting techniques. On the other hand, cement block making machines are designed to produce blocks with minimal waste, as they can accurately cut and shape the blocks to the desired specifications. This results in a more efficient use of resources and reduced waste disposal costs for construction companies.

Furthermore, cement block making machines are highly energy-efficient, contributing to the overall reduction of carbon emissions in the construction industry. These machines are equipped with advanced technologies that optimize energy consumption during the block production process. By investing in a cement block making machine, construction companies can reduce their carbon footprint and contribute to a more sustainable environment.

In addition to environmental benefits, investing in a cement block making machine also offers financial advantages for construction companies. The efficient production process of these machines allows for higher output levels in a shorter period of time, resulting in increased productivity and profitability. Moreover, the durability and quality of the cement blocks produced by these machines ensure long-lasting structures that require minimal maintenance and repairs, ultimately saving construction companies both time and money in the long run.

Another important aspect to consider when investing in a cement block making machine is the versatility it offers in terms of design and customization. These machines are capable of producing a wide range of cement block sizes and shapes, allowing construction companies to meet the diverse needs of their clients. From standard blocks for residential buildings to specialized blocks for infrastructure projects, cement block making machines provide endless possibilities for customization and creativity in construction.

In conclusion, the advantages of investing in a cement block making machine go beyond just improving productivity and profitability for construction companies. These machines play a crucial role in promoting environmental sustainability and waste reduction in the construction industry. By reducing waste generation, optimizing energy consumption, and offering design versatility, cement block making machines are paving the way towards a more sustainable future for the construction sector. Investing in these machines not only benefits construction companies but also contributes to a healthier planet for future generations.

Conclusion

In conclusion, investing in a cement block making machine is a wise decision for any company in the construction industry. Not only does it offer numerous advantages such as increased productivity, cost savings, and high-quality output, but it also ensures long-term success and growth. With our 18 years of experience in the industry, we understand the importance of investing in reliable and efficient equipment to stay ahead of the competition. So, don't hesitate to take the leap and invest in a cement block making machine today to unlock the potential for greater success and profitability in your business.