The Ultimate Guide To Choosing The Best Cement Block Machine For Your Construction Needs

Are you in the market for a cement block machine for your construction projects but overwhelmed by the options available? Look no further! Our comprehensive guide is here to help you navigate through the plethora of choices and select the best machine that suits your specific needs. From understanding the different types of machines to key features to consider, we've got you covered. Let's simplify the process and ensure you make the right choice for your next construction project.

- Understanding the Different Types of Cement Block Machines

Cement block machines are essential tools for any construction project involving concrete blocks. These machines come in a variety of types, each with its own unique features and capabilities. Understanding the different types of cement block machines available is crucial when selecting the best machine for your specific construction needs.

One of the most common types of cement block machines is the manual block machine. These machines are operated manually, requiring human labor to mold and shape the concrete blocks. Manual block machines are typically smaller and more affordable than other types of machines, making them suitable for small construction projects or for use in areas where access to electricity may be limited.

Another popular type of cement block machine is the semi-automatic block machine. Semi-automatic machines require some manual labor, but also have automated features that can help speed up the block-making process. These machines are suitable for medium-sized construction projects and are generally more efficient than manual machines.

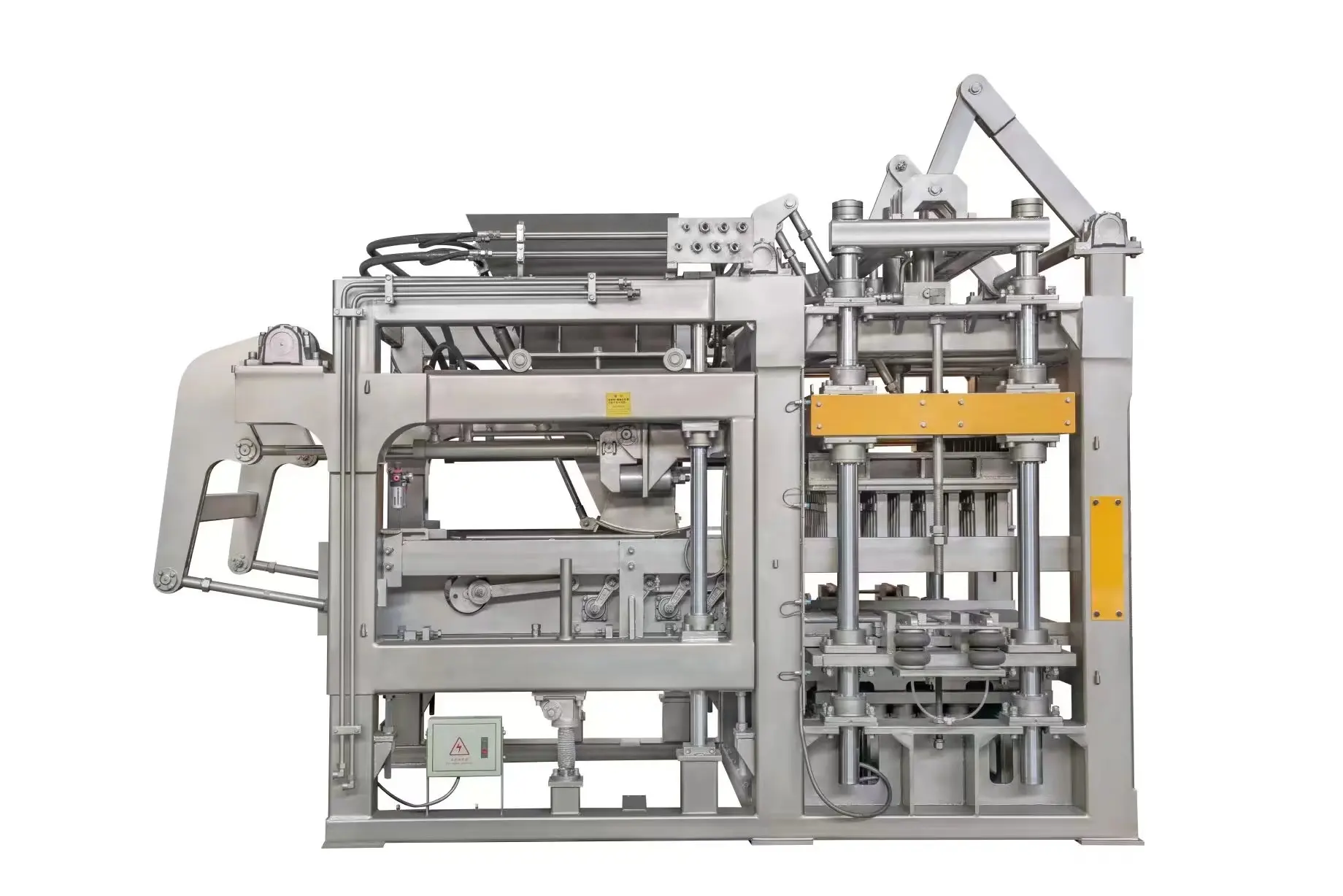

For large-scale construction projects, fully automatic block machines are often the best option. These machines are fully automated, requiring minimal human intervention. Fully automatic block machines can produce a large number of concrete blocks quickly and efficiently, making them ideal for large construction projects or commercial applications.

In addition to manual, semi-automatic, and fully automatic machines, there are also specialized cement block machines designed for specific tasks. For example, vibration table machines are used to compact and mold concrete blocks, while hydraulic block machines use hydraulic pressure to produce high-quality blocks.

When choosing a cement block machine, it is important to consider factors such as the size of the project, the available space for the machine, and the desired output. Manual machines may be suitable for small DIY projects, while fully automatic machines are better suited for large commercial projects.

In conclusion, selecting the best cement block machine for your construction needs requires careful consideration of the different types of machines available. By understanding the unique features and capabilities of manual, semi-automatic, and fully automatic machines, as well as other specialized machines, you can choose the machine that is best suited for your specific project requirements.

- Factors to Consider When Selecting a Cement Block Machine

When it comes to selecting a cement block machine for your construction needs, there are several factors that need to be taken into consideration to ensure that you are choosing the best machine for the job. Cement block machines are essential in the construction industry as they are used to produce high-quality cement blocks that are essential for building structures such as homes, commercial buildings, and various infrastructure projects.

One of the most important factors to consider when selecting a cement block machine is the production capacity of the machine. The production capacity of the machine will determine how many cement blocks it can produce in a given period of time. It is important to choose a machine with a production capacity that matches the needs of your construction project. If you have a large construction project, you will need a machine with a higher production capacity to ensure that you can meet your construction deadlines.

Another factor to consider when selecting a cement block machine is the size and type of cement blocks that the machine can produce. Cement block machines come in a variety of sizes and are capable of producing different types of cement blocks such as solid blocks, hollow blocks, interlocking blocks, and paving blocks. It is important to choose a machine that can produce the type and size of cement blocks that are required for your construction project.

The quality of the cement blocks produced by the machine is also an important factor to consider. It is essential to choose a machine that can produce high-quality cement blocks that are durable and meet the required standards for construction. Poor quality cement blocks can compromise the integrity of a building and can lead to costly repairs in the future. Look for a machine that is known for producing high-quality cement blocks that are strong and durable.

The efficiency and reliability of the machine are also important factors to consider when selecting a cement block machine. An efficient machine will be able to produce cement blocks quickly and with minimal waste, saving you time and money on your construction project. A reliable machine will be able to operate consistently without breaking down or causing delays in your construction schedule. Look for a machine that is well-built and has a reputation for being reliable and efficient.

In conclusion, when selecting a cement block machine for your construction needs, it is important to consider factors such as production capacity, size and type of cement blocks produced, quality of the blocks, and the efficiency and reliability of the machine. By taking these factors into consideration, you can choose the best cement block machine for your construction project and ensure the success of your building project.

- Evaluating the Production Capacity of Cement Block Machines

When it comes to choosing the best cement block machine for your construction needs, one of the most important factors to consider is the evaluation of its production capacity. The production capacity of a cement block machine refers to the amount of blocks it can produce in a specific period of time, typically measured in blocks per hour or blocks per day.

The production capacity of a cement block machine is crucial because it directly impacts the efficiency and profitability of your construction project. A machine with a higher production capacity can produce more blocks in less time, allowing you to complete your project faster and save on labor costs. On the other hand, a machine with a lower production capacity may slow down your project and increase overall costs.

There are several factors that can affect the production capacity of a cement block machine. One of the key factors is the type and size of the machine. Different types of cement block machines, such as manual, semi-automatic, and fully automatic machines, have different production capacities. Fully automatic machines, for example, are typically faster and more efficient than manual machines, as they require less manual labor and can produce more blocks in a shorter period of time.

Another factor that can impact the production capacity of a cement block machine is the quality of its components and materials. Machines with high-quality components and materials are more durable and reliable, allowing them to maintain a consistent production capacity over time. On the other hand, machines with low-quality components may break down more frequently, leading to downtime and reduced production capacity.

It is also important to consider the power source of the cement block machine, as this can affect its production capacity. Machines that are powered by electricity or diesel engines are typically more powerful and can produce more blocks than machines that are manually operated. Additionally, machines that are equipped with advanced features, such as automatic block stacking systems or hydraulic controls, can also increase their production capacity.

In conclusion, when choosing the best cement block machine for your construction needs, it is essential to carefully evaluate its production capacity. By considering factors such as the type and size of the machine, the quality of its components, and its power source, you can determine which machine is best suited for your specific project requirements. Investing in a cement block machine with a high production capacity can help you save time and money, while ensuring that your construction project is completed efficiently and on schedule.

- Comparing Features and Technologies of Cement Block Machines

When it comes to selecting the right cement block machine for your construction needs, it is essential to compare the features and technologies of different models. This ultimate guide will provide you with a comprehensive overview of the factors to consider when making this crucial decision.

One of the most important things to consider when choosing a cement block machine is the production capacity. The production capacity of a machine is determined by the number of blocks it can produce in a given time frame. This is crucial as it will directly impact the efficiency of your construction project. It is essential to assess your project requirements and choose a machine that can meet your production needs.

Another crucial factor to consider is the type of blocks the machine can produce. Different machines are designed to produce various types of blocks such as solid blocks, hollow blocks, paving blocks, and interlocking blocks. It is important to choose a machine that can produce the type of blocks you require for your construction project.

The technology used in a cement block machine is also a significant consideration. Advanced technologies such as hydraulic systems and automatic control systems can significantly enhance the performance and efficiency of a machine. It is essential to select a machine that incorporates the latest technologies to ensure optimal results.

The ease of operation and maintenance of a cement block machine are also crucial factors to consider. A machine that is easy to operate and requires minimal maintenance will save you time and effort in the long run. Additionally, consider the availability of spare parts and technical support for the machine to ensure seamless operation.

When comparing different cement block machines, it is important to consider the overall cost of ownership. This includes not only the initial purchase price but also factors such as energy consumption, maintenance costs, and potential downtime. Calculate the total cost of ownership for each machine to make an informed decision.

In conclusion, choosing the best cement block machine for your construction needs requires careful consideration of various factors such as production capacity, block types, technology, ease of operation, and overall cost of ownership. By comparing the features and technologies of different machines, you can select a machine that will meet your requirements and ensure the success of your construction project.

- Making the Final Decision: Choosing the Best Cement Block Machine for Your Project

When it comes to construction projects, one of the key components needed is a reliable cement block machine. This essential piece of equipment is responsible for producing the cement blocks that will form the foundation of your structure. With a wide range of options available on the market, choosing the best cement block machine for your specific project can be a daunting task. In this ultimate guide, we will explore everything you need to consider in order to make the final decision on selecting the right cement block machine for your construction needs.

First and foremost, it is crucial to understand the different types of cement block machines available. There are various types of machines, such as manual, semi-automatic, and fully automatic machines. Each type has its own set of features and capabilities, so it is important to carefully evaluate your project requirements to determine which type of machine will best suit your needs.

Next, consider the production capacity of the cement block machine. The production capacity of the machine will determine how many blocks it can produce in a given time frame. It is essential to choose a machine with a production capacity that aligns with the scale of your project. For smaller projects, a machine with a lower production capacity may be sufficient, while larger projects may require a machine with a higher production capacity.

In addition to production capacity, it is important to consider the quality of the cement blocks produced by the machine. Look for a machine that is known for producing high-quality, durable blocks that meet industry standards. This will ensure that your construction project is built to last and withstand the test of time.

Another key factor to consider when choosing a cement block machine is the ease of operation and maintenance. Look for a machine that is user-friendly and easy to operate, as this will help streamline the production process and minimize downtime. Additionally, consider the maintenance requirements of the machine and choose one that is easy to maintain and repair.

When it comes to choosing the best cement block machine for your project, it is important to consider your budget. Take into account the initial cost of the machine, as well as any ongoing maintenance and operation costs. While it may be tempting to opt for a cheaper machine, it is important to remember that quality and reliability are paramount when it comes to construction equipment.

In conclusion, choosing the best cement block machine for your construction needs requires careful consideration of the machine type, production capacity, quality of blocks produced, ease of operation and maintenance, and budget. By taking the time to evaluate these factors and make an informed decision, you can ensure that your construction project is completed efficiently and successfully.

Conclusion

In conclusion, choosing the best cement block machine for your construction needs is a crucial decision that can make or break your project. With 18 years of experience in the industry, we understand the importance of investing in high-quality equipment that is reliable, efficient, and cost-effective. By following the ultimate guide provided in this article, you can confidently select the right cement block machine that meets your specific requirements and helps you achieve success in your construction projects. Remember, when it comes to building a solid foundation for your project, investing in the best equipment is key. Let our expertise and knowledge guide you towards making the right choice for your construction needs.