The Ultimate Guide To Interlocking Block Making Machine Prices

Are you looking to invest in an interlocking block making machine but unsure of where to start? Look no further! In this comprehensive guide, we break down everything you need to know about interlocking block making machine prices. From budget-friendly options to top-of-the-line models, we've got you covered. Read on to find the perfect machine for your needs and budget.

- Understanding the Different Types of Interlocking Block Making Machines

Interlocking block making machines are essential equipment for construction projects around the world. These machines play a crucial role in creating strong and durable interlocking blocks that are used for building various structures such as walls, pavements, and driveways. Understanding the different types of interlocking block making machines is essential for getting the best value for your investment. In this comprehensive guide, we will explore the various types of interlocking block making machines available in the market and provide insights into their prices.

The first type of interlocking block making machine is the manual machine, which is typically operated by hand. These machines are suitable for small-scale projects and are more affordable compared to automated machines. Manual machines are easy to use and maintain, making them a popular choice for homeowners and small contractors.

The second type of interlocking block making machine is the semi-automatic machine, which requires minimal human intervention during the block-making process. These machines offer higher productivity and efficiency compared to manual machines, making them ideal for medium-scale construction projects. Semi-automatic machines come with advanced features such as vibration technology and hydraulic pressure systems, which ensure high-quality and consistent output.

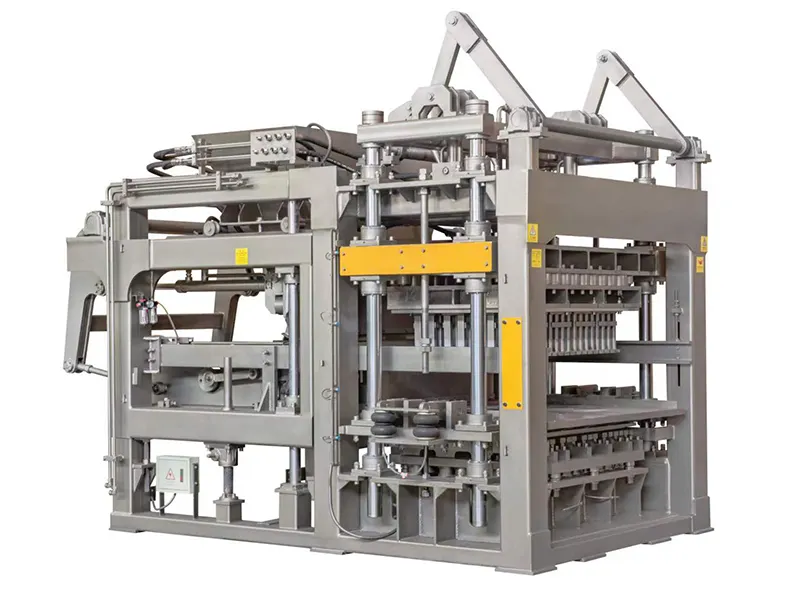

The third type of interlocking block making machine is the fully automatic machine, which is capable of producing large volumes of interlocking blocks with minimal human supervision. These machines are equipped with cutting-edge technology and computerized controls, allowing for precise and efficient block production. Fully automatic machines are suitable for large-scale construction projects where speed and productivity are essential.

When it comes to interlocking block making machine prices, manual machines are the most affordable option, with prices ranging from $1000 to $5000 depending on the size and capacity. Semi-automatic machines are priced between $5000 and $15000, while fully automatic machines can cost anywhere from $15000 to $50000 or more, depending on the features and specifications.

In conclusion, understanding the different types of interlocking block making machines is crucial for choosing the right machine for your construction project. Whether you opt for a manual, semi-automatic, or fully automatic machine, it is essential to consider factors such as output capacity, production efficiency, and price. By investing in a high-quality interlocking block making machine, you can ensure the success of your construction project and achieve long-lasting results.

- Factors that Influence Interlocking Block Making Machine Prices

Interlocking block making machines have revolutionized the construction industry, offering a cost-effective and efficient way to produce sturdy and durable blocks for building projects. However, before investing in one of these machines, it is crucial to understand the various factors that can influence their prices.

One of the key factors that can impact interlocking block making machine prices is the quality of the machine. Higher quality machines, typically made with more durable materials and advanced technology, will come with a higher price tag. These machines are designed to be more reliable and efficient, producing high-quality blocks with minimal downtime. While they may cost more upfront, the long-term benefits in terms of productivity and block quality can outweigh the initial investment.

Another factor that can influence interlocking block making machine prices is the production capacity of the machine. Machines with higher production capacities, capable of producing more blocks per hour, will generally cost more than machines with lower capacities. The size and scale of your construction projects will play a significant role in determining the production capacity you require, so it is important to consider this factor when comparing prices.

Additionally, the level of automation in the machine can also impact its price. Fully automated machines that require minimal manual intervention will be more expensive than semi-automated or manual machines. While automated machines can increase productivity and efficiency, they may not be necessary for smaller-scale projects. It is important to balance the level of automation with your specific needs and budget.

The brand and reputation of the manufacturer can also influence interlocking block making machine prices. Established manufacturers with a track record of producing high-quality machines may charge a premium for their products. While these machines may come with a higher price tag, the reputation of the manufacturer can provide assurance of reliability and customer support.

In addition to these factors, market demand and competition can also impact interlocking block making machine prices. Prices may fluctuate based on supply and demand, as well as the level of competition in the market. It is important to research and compare prices from multiple manufacturers to ensure you are getting the best value for your investment.

In conclusion, interlocking block making machine prices can vary based on a variety of factors, including the quality of the machine, production capacity, level of automation, manufacturer reputation, and market conditions. By considering these factors and conducting thorough research, you can make an informed decision when purchasing an interlocking block making machine for your construction projects.

- Comparison of Prices from Different Manufacturers

Interlocking block making machines have become a popular choice for construction projects due to their efficiency and cost-effectiveness. However, when it comes to purchasing one of these machines, the price can vary significantly depending on the manufacturer. In this article, we will provide you with a comprehensive guide to interlocking block making machine prices, comparing prices from different manufacturers to help you make an informed decision.

One of the key factors to consider when looking at interlocking block making machine prices is the type of machine you need. There are various types of interlocking block making machines available on the market, ranging from manual to automatic machines. Manual machines are typically cheaper, but they require more labor and time to operate. On the other hand, automatic machines are more expensive, but they are more efficient and require less manual labor.

In terms of prices, manual interlocking block making machines can range from $2000 to $5000, depending on the size and features of the machine. Automatic machines, on the other hand, can cost anywhere from $10,000 to $50,000 or more. It is important to consider your budget and the scale of your construction project when deciding on the type of machine to purchase.

When comparing prices from different manufacturers, it is also important to consider the quality of the machine. Some manufacturers may offer lower prices, but their machines may not be as durable or reliable as those from higher-priced manufacturers. It is important to do your research and read reviews from other customers to ensure that you are getting a high-quality machine that will meet your needs.

In addition to the upfront cost of the machine, it is also important to consider the ongoing maintenance and operating costs. Some machines may require regular maintenance and replacement parts, which can add to the overall cost of owning the machine. It is important to factor in these costs when comparing prices from different manufacturers.

In conclusion, when looking to purchase an interlocking block making machine, it is important to consider the price from different manufacturers. By comparing prices, you can ensure that you are getting a high-quality machine at a competitive price. Remember to consider the type of machine, the quality of the manufacturer, and the ongoing maintenance costs when making your decision. By following this guide, you can find the ultimate interlocking block making machine at the best price for your construction project.

- Tips for Finding the Best Deal on an Interlocking Block Making Machine

Interlocking block making machines have revolutionized the construction industry, making it easier and more cost-effective to produce high-quality interlocking blocks for various building projects. However, finding the best deal on an interlocking block making machine can be a daunting task, especially with the wide range of prices and options available in the market. In this comprehensive guide, we will provide you with tips and strategies to help you find the best deal on an interlocking block making machine.

1. Research and Compare Prices:

Before making a purchase, it is crucial to research and compare prices from different suppliers and manufacturers. Look for reputable companies that offer competitive prices and high-quality machines. While it may be tempting to opt for the cheapest option, it is important to consider the quality and reliability of the machine as well.

2. Consider the Features and Specifications:

When comparing prices, it is essential to consider the features and specifications of the interlocking block making machine. Look for machines that are durable, efficient, and easy to use. Consider factors such as production capacity, power consumption, and the type of blocks the machine can produce. Investing in a machine with advanced features and capabilities may save you money in the long run.

3. Take Advantage of Discounts and Promotions:

Many suppliers offer discounts and promotions on interlocking block making machines, especially during certain times of the year. Keep an eye out for special offers and deals that can help you save money on your purchase. Additionally, some suppliers may offer financing options or payment plans to make the machine more affordable.

4. Negotiate the Price:

Don't be afraid to negotiate the price with the supplier or manufacturer. Many companies are willing to negotiate on the price, especially if you are purchasing multiple machines or accessories. Be prepared to walk away if you are not satisfied with the price, as there are plenty of other options available in the market.

5. Consider Used or Refurbished Machines:

If you are on a tight budget, consider purchasing a used or refurbished interlocking block making machine. While these machines may have some wear and tear, they can still provide reliable performance at a fraction of the cost of a new machine. Just make sure to inspect the machine thoroughly before making a purchase.

In conclusion, finding the best deal on an interlocking block making machine requires careful consideration and research. By comparing prices, considering features and specifications, taking advantage of discounts, negotiating the price, and considering used machines, you can find a high-quality machine at a price that fits your budget. With these tips in mind, you can make an informed decision and invest in a machine that will help you produce high-quality interlocking blocks for your construction projects.

- How to Properly Maintain and Care for Your Interlocking Block Making Machine

Interlocking block making machines have become increasingly popular in the construction industry due to their efficiency and ease of use. However, in order to ensure that your machine continues to operate at its optimal level, it is important to properly maintain and care for it. In this ultimate guide, we will discuss how to properly maintain and care for your interlocking block making machine to ensure that it remains in top working condition.

One of the most important aspects of maintaining your interlocking block making machine is regular cleaning. Dust, dirt, and other debris can build up in the machine over time, causing it to operate less efficiently. Regularly cleaning the machine with a damp cloth or brush can help to remove any buildup and ensure that it continues to run smoothly.

In addition to regular cleaning, it is also important to lubricate all moving parts of the interlocking block making machine. This will help to reduce friction and wear on the components, extending the lifespan of the machine. Be sure to use a high-quality lubricant that is specifically designed for use on construction equipment.

Another important aspect of maintaining your interlocking block making machine is to regularly inspect all parts for wear and tear. Replace any worn or damaged parts immediately to prevent further damage to the machine. This can help to prevent costly repairs down the line and ensure that your machine continues to operate at its best.

In addition to regular maintenance, it is also important to use the machine properly to prevent damage. Follow the manufacturer's instructions for operating the machine and avoid overloading it with materials. Doing so can help to prevent unnecessary wear and tear on the machine and ensure that it continues to produce high-quality interlocking blocks.

When it comes to pricing for interlocking block making machines, there are a few factors to consider. The size and capacity of the machine, as well as the brand and features, can all impact the price. Additionally, the location and supplier may also affect the price. It is important to research different options and compare prices to find the best deal for your needs.

In conclusion, proper maintenance and care are essential for ensuring that your interlocking block making machine continues to operate at its best. By following the tips outlined in this guide, you can help to extend the lifespan of your machine and prevent costly repairs. Remember to clean, lubricate, inspect, and operate the machine properly to keep it in top working condition. By investing the time and effort into maintaining your machine, you can ensure that it continues to produce high-quality interlocking blocks for years to come.

Conclusion

In conclusion, the ultimate guide to interlocking block making machine prices has provided valuable insights for those looking to invest in this industry. With 18 years of experience, our company has a deep understanding of the market and can provide top-notch products at competitive prices. By choosing the right machine for your needs and budget, you can streamline the production process and increase efficiency in your operations. Whether you are a seasoned professional or a newcomer to the industry, investing in a high-quality interlocking block making machine is a smart decision that can pay off in the long run. Thank you for following along with us on this journey of discovery, and we look forward to helping you achieve success in your business endeavors.