The Ultimate Guide To Selecting The Best Cement Interlock Machine For Your Project

Are you looking to enhance the efficiency and quality of your construction project? Look no further than our comprehensive guide on selecting the best cement interlock machine for your needs. With an array of options available, choosing the right machine can make all the difference in the success of your project. Follow our expert tips and recommendations to ensure you make the most informed decision for your construction needs.

- Understanding the Different Types of Cement Interlock Machines

Cement interlock machines are essential equipment for any construction project involving the laying of interlocking bricks or blocks. These machines come in various types, each suited for different purposes and project requirements. In this article, we will delve into the different types of cement interlock machines available on the market, their features, and how to select the best one for your project.

1. Manual cement interlock machines:

Manual cement interlock machines are the most basic and affordable option available. These machines are operated manually by a person, requiring physical effort to press the mixture of cement and sand into the molds to produce interlocking bricks. While manual machines are cost-effective, they are labor-intensive and have a lower production capacity compared to automated machines.

2. Semi-automatic cement interlock machines:

Semi-automatic cement interlock machines combine manual operation with some automation. These machines are equipped with features such as a hydraulic system for pressing the bricks, reducing the manual effort required. Semi-automatic machines offer higher production capacity and efficiency compared to manual machines, making them suitable for medium-sized construction projects.

3. Fully automatic cement interlock machines:

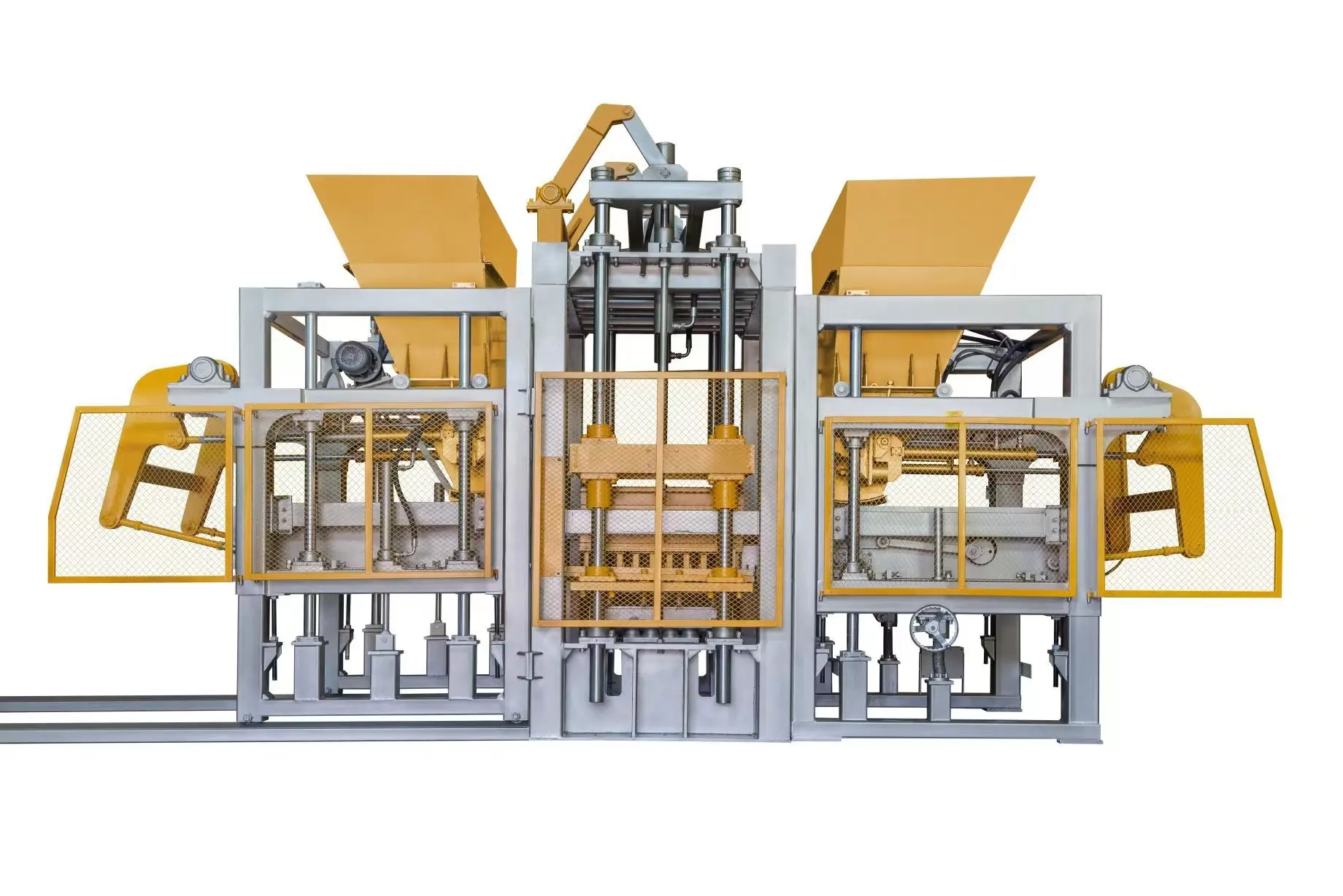

Fully automatic cement interlock machines are the most advanced and efficient option available. These machines are equipped with advanced technology such as PLC systems, automatic feeding systems, and hydraulic controls, enabling them to produce a large number of interlocking bricks with minimal human intervention. Fully automatic machines are ideal for large-scale construction projects that require high production capacity and precision.

When selecting a cement interlock machine for your project, consider the following factors:

1. Production capacity: Determine the amount of interlocking bricks you need to produce per day to meet your project requirements. Choose a machine that can accommodate your production capacity needs.

2. Automation level: Consider the level of automation you require based on the size and complexity of your project. Fully automatic machines are suitable for large projects, while manual or semi-automatic machines may be sufficient for smaller projects.

3. Budget: Evaluate your budget and choose a machine that offers the best value for money in terms of features, production capacity, and durability.

4. Maintenance and support: Choose a reputable manufacturer that offers reliable after-sales support and maintenance services to ensure the longevity and efficiency of your cement interlock machine.

In conclusion, selecting the best cement interlock machine for your project requires careful consideration of your production capacity, automation requirements, budget, and maintenance needs. By understanding the different types of cement interlock machines available and their features, you can make an informed decision that will help you achieve optimal results in your construction project.

- Factors to Consider When Choosing a Cement Interlock Machine

When embarking on a construction project that involves the use of cement interlock machines, it is crucial to select the best machine for your specific needs. With a wide range of options available in the market, it can be overwhelming to make the right choice. However, by considering certain factors, you can ensure that you choose the most suitable cement interlock machine for your project.

One of the first factors to consider when selecting a cement interlock machine is the type of interlocking bricks or blocks you will be producing. Different machines are designed to produce different types of interlocking bricks, so it is important to choose a machine that is compatible with the specific design and size of bricks you require for your project. Additionally, consider the production capacity of the machine, as this will determine how many bricks or blocks can be produced in a given timeframe.

Another important factor to consider is the power source of the cement interlock machine. While some machines are powered by electricity, others may require diesel or gasoline. Consider the availability of the power source in your location, as well as any additional costs associated with operating the machine. Additionally, consider the maintenance requirements of the machine, as regular maintenance is essential to ensure the longevity and efficiency of the machine.

Furthermore, when choosing a cement interlock machine, it is crucial to consider the quality and reliability of the machine. Look for a machine that is manufactured by a reputable company with a track record of producing high-quality machines. Read reviews and testimonials from other customers to get an idea of the performance and reliability of the machine. Additionally, consider the warranty and after-sales support offered by the manufacturer, as this can provide added peace of mind in case of any issues with the machine.

In addition to the technical aspects of the machine, it is also important to consider the cost of the machine and your budget constraints. Compare prices from different manufacturers and suppliers to find a machine that offers the best value for money. Additionally, consider any additional costs such as shipping and installation fees, as well as the cost of any necessary accessories or spare parts.

In conclusion, selecting the best cement interlock machine for your project requires careful consideration of various factors. By taking into account the type of bricks or blocks you need, the power source, production capacity, quality, reliability, and cost of the machine, you can ensure that you choose a machine that meets your requirements and delivers efficient and high-quality results for your construction project.

- Comparing the Efficiency and Output of Various Cement Interlock Machines

Cement interlock machines, also known as paving block machines, are essential equipment in the construction industry for producing interlocking concrete blocks, pavers, and tiles. These machines are widely used in the production of pavement bricks for driveways, walkways, and other outdoor surfaces. With a wide variety of cement interlock machines available on the market, it can be challenging to select the best one for your specific project. This ultimate guide aims to help you make an informed decision by comparing the efficiency and output of various cement interlock machines.

Efficiency is a crucial factor to consider when selecting a cement interlock machine. Efficiency refers to the machine's ability to produce a large quantity of interlocking blocks in a relatively short amount of time. This is determined by factors such as the machine's production capacity, speed, and power consumption. Machines with higher production capacities and faster cycle times are more efficient and can help you complete your project in a timely manner.

Output is another important consideration when choosing a cement interlock machine. Output refers to the quality of the interlocking blocks produced by the machine. The output quality is influenced by factors such as the machine's design, construction, and the materials used in the manufacturing process. Machines that are well-built and use high-quality materials are likely to produce durable and aesthetically pleasing interlocking blocks.

When comparing the efficiency and output of various cement interlock machines, it is essential to consider the specific requirements of your project. For example, if you are working on a large-scale commercial project, you may need a machine with a high production capacity and fast cycle times. On the other hand, if you are working on a small residential project, a machine with a lower production capacity may be sufficient.

In addition to efficiency and output, there are other factors to consider when selecting a cement interlock machine, such as the machine's maintenance requirements, versatility, and ease of operation. Some machines require regular maintenance to ensure optimal performance, while others are designed for low-maintenance operation. Versatile machines can produce a variety of interlocking block shapes and sizes, making them suitable for a wide range of projects. Machines that are easy to operate are ideal for beginners or operators with limited experience.

In conclusion, selecting the best cement interlock machine for your project requires careful consideration of factors such as efficiency, output, maintenance requirements, versatility, and ease of operation. By comparing the efficiency and output of various machines, you can make an informed decision that meets your specific project requirements. Whether you are working on a small residential project or a large commercial project, choosing the right cement interlock machine is essential for achieving high-quality results.

- Features to Look for in a High-Quality Cement Interlock Machine

If you are in the market for a high-quality cement interlock machine for your upcoming project, there are several key features that you should be on the lookout for. Investing in the right machine can make a huge difference in the efficiency and quality of your construction process, so it is important to do your research and choose wisely.

One of the most important features to consider when selecting a cement interlock machine is its production capacity. Depending on the size and scope of your project, you will need a machine that can produce a sufficient number of interlocking bricks or blocks per day. Look for a machine that has a high production capacity to ensure that you can meet your project deadlines without any delays.

Another crucial factor to consider is the quality of the materials used in the construction of the machine. A high-quality cement interlock machine should be built to last, with durable components that can withstand the rigors of daily use. Look for machines that are made from high-grade steel and other quality materials to ensure longevity and reliability.

In addition to production capacity and construction quality, you should also consider the versatility of the machine. Look for a cement interlock machine that is capable of producing a variety of different interlocking brick sizes and shapes. This will give you the flexibility to adapt to different project requirements and produce custom designs as needed.

Another important feature to look for in a high-quality cement interlock machine is ease of use. The machine should be user-friendly and easy to operate, with intuitive controls that make it simple for even inexperienced operators to produce high-quality interlocking bricks. Look for machines that come with comprehensive training materials and support to ensure that you can get up and running quickly and easily.

Finally, consider the level of support and service that the manufacturer offers. Choose a reputable manufacturer that provides excellent customer service and technical support to assist you with any issues that may arise. Look for machines that come with a warranty to protect your investment and give you peace of mind.

In conclusion, selecting the best cement interlock machine for your project requires careful consideration of several key features. By choosing a machine with a high production capacity, durable construction, versatility, ease of use, and excellent support, you can ensure that your construction project runs smoothly and efficiently. Take the time to research different options and choose a machine that meets your specific needs and requirements.

- Tips for Maintaining and Maximizing the Performance of Your Cement Interlock Machine

Cement interlock machines are essential equipment for any construction project that involves laying interlocking cement blocks. These machines are designed to streamline the process of producing interlocking blocks, ensuring a consistent and high-quality end product. However, like any machinery, cement interlock machines require regular maintenance and care to ensure optimal performance. In this article, we will discuss some important tips for maintaining and maximizing the performance of your cement interlock machine.

Tip 1: Regular Cleaning and Lubrication

One of the most important aspects of maintaining a cement interlock machine is regular cleaning and lubrication. Over time, dust, dirt, and debris can accumulate on the machine, leading to decreased performance and potential damage. It is important to clean the machine regularly using a damp cloth and mild detergent. Additionally, lubricating the moving parts of the machine with a suitable lubricant will help prevent wear and tear, ensuring smooth operation.

Tip 2: Check and Replace Worn Parts

Another key aspect of maintaining a cement interlock machine is to regularly check for worn or damaged parts and replace them promptly. Worn parts can negatively impact the performance of the machine and lead to costly repairs down the line. It is important to inspect the machine regularly and replace any worn parts, such as belts, chains, and bearings, as needed.

Tip 3: Proper Storage

Proper storage of the cement interlock machine is essential for maintaining its performance and longevity. Store the machine in a clean, dry, and well-ventilated area to prevent rust and corrosion. Additionally, cover the machine with a tarp or protective cover when not in use to shield it from dust and debris.

Tip 4: Follow Manufacturer's Instructions

It is important to familiarize yourself with the manufacturer's instructions for operating and maintaining your cement interlock machine. These instructions will provide valuable information on proper usage, maintenance procedures, and troubleshooting tips. By following the manufacturer's instructions, you can ensure that your machine operates efficiently and effectively.

Maximizing the Performance of Your Cement Interlock Machine

In addition to regular maintenance, there are several strategies you can implement to maximize the performance of your cement interlock machine. These include:

1. Using high-quality materials: Using high-quality cement and aggregates will ensure that your interlocking blocks are durable and long-lasting.

2. Proper training: Ensure that all operators are properly trained in the use and maintenance of the cement interlock machine to prevent accidents and damage.

3. Regular inspection: Conduct regular inspections of the machine to identify any potential issues early and address them promptly.

By following these tips for maintaining and maximizing the performance of your cement interlock machine, you can ensure that your construction project runs smoothly and efficiently. Remember, investing time and effort in the maintenance of your machine will pay off in the long run with consistent high-quality results.

Conclusion

In conclusion, choosing the best cement interlock machine for your project is a crucial decision that can greatly impact the success of your construction endeavors. With our 18 years of experience in the industry, we have compiled the ultimate guide to help you make an informed choice. By considering factors such as production capacity, automation features, and overall cost, you can select the machine that best suits your project requirements. Remember, investing in a high-quality cement interlock machine will not only streamline your construction process but also ensure long-lasting and durable results. So, don't hesitate to reach out to our team for expert guidance and recommendations. Happy building!