The Ultimate Guide To Selecting The Best Concrete Brick Making Machine For Your Project

Are you ready to take your construction project to the next level? Look no further than our comprehensive guide on selecting the best concrete brick making machine for your specific needs. Whether you are a seasoned professional or a DIY enthusiast, this article covers everything you need to know to make an informed decision and ensure success in your brick-making endeavors. Read on to discover valuable tips, insights, and recommendations that will help you find the perfect machine for your project.

- Understanding the Different Types of Concrete Brick Making Machines

When it comes to selecting the best concrete brick making machine for your project, it is important to understand the different types available on the market. Concrete brick making machines come in a variety of shapes and sizes, each designed for specific purposes and types of bricks. In this ultimate guide, we will delve into the various types of concrete brick making machines to help you make an informed decision.

1. Manual Concrete Brick Making Machines:

Manual concrete brick making machines are typically smaller in size and require human intervention for the brick molding process. These machines are ideal for small-scale projects or for those on a budget. While they may require more effort and time compared to automated machines, manual concrete brick making machines can still produce quality bricks for your project.

2. Semi-Automatic Concrete Brick Making Machines:

Semi-automatic concrete brick making machines are a step up from manual machines, as they require less human intervention during the brick molding process. These machines are suitable for medium to large-scale projects and offer increased efficiency and productivity. With semi-automatic machines, the mixing, molding, and curing processes are partially automated, making them a popular choice for many construction projects.

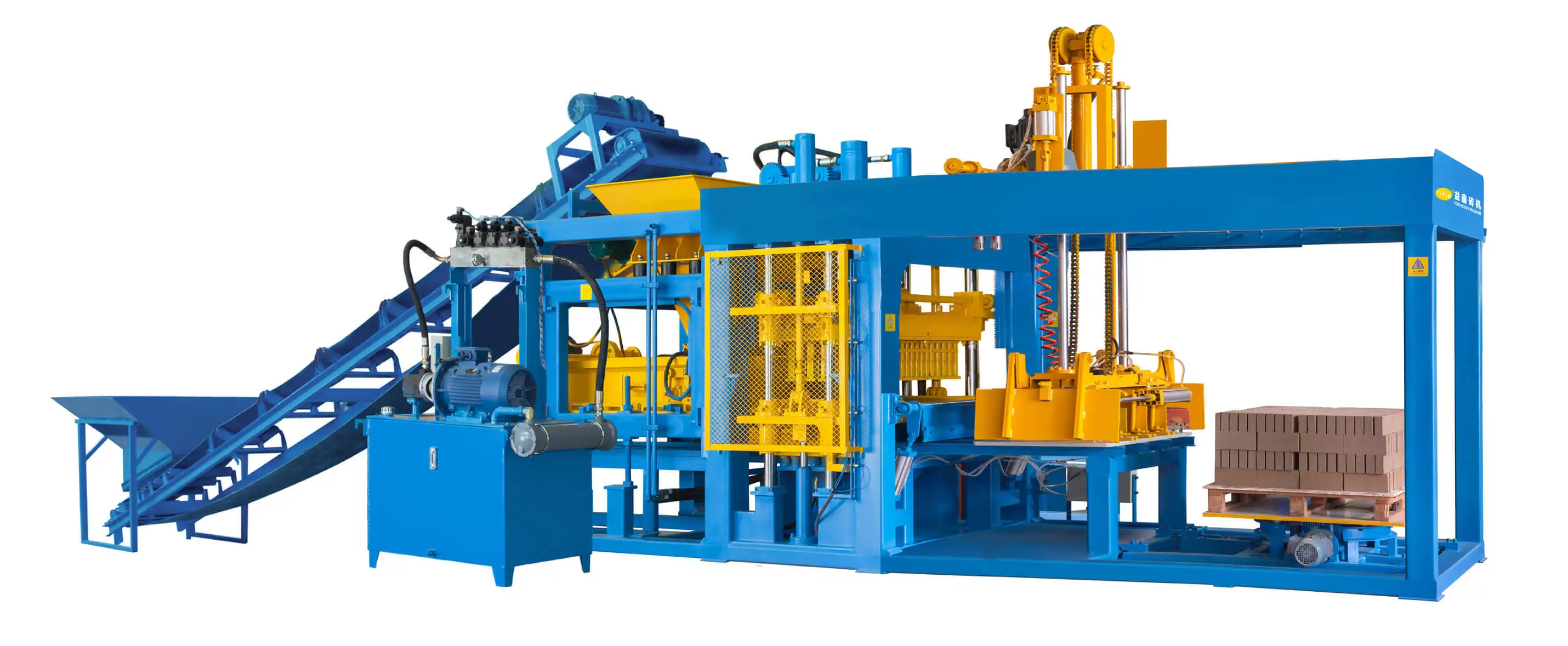

3. Fully Automatic Concrete Brick Making Machines:

Fully automatic concrete brick making machines are the most advanced and efficient option available. These machines are fully automated, from raw material feeding to brick stacking, reducing the need for human labor and increasing productivity. Fully automatic machines are ideal for large-scale projects where speed and precision are crucial. While they may come with a higher price tag, the increased efficiency and output make them a worthwhile investment for serious builders.

4. Hydraulic Concrete Brick Making Machines:

Hydraulic concrete brick making machines utilize hydraulic pressure to compress and mold the raw materials into bricks. These machines offer high strength and precision in brick production, making them suitable for projects that require durable and quality bricks. Hydraulic machines also allow for customization in brick shapes and sizes, giving builders more flexibility in design options.

5. Mobile Concrete Brick Making Machines:

Mobile concrete brick making machines are portable and compact, making them ideal for on-site brick production. These machines are versatile and convenient for projects that require bricks to be made directly at the construction site. Mobile machines are also excellent for remote areas where traditional brick-making facilities may not be readily available.

In conclusion, selecting the best concrete brick making machine for your project requires careful consideration of your project's scale, budget, and specific requirements. Whether you opt for a manual, semi-automatic, or fully automatic machine, understanding the different types available will help you make an informed decision that meets your construction needs. Remember to also consider factors such as output capacity, brick quality, and maintenance requirements when choosing a concrete brick making machine for your next project.

- Factors to Consider When Choosing a Concrete Brick Making Machine

When embarking on a project that involves the production of concrete bricks, one of the most crucial decisions you'll have to make is selecting the right concrete brick making machine. With a plethora of options available on the market, choosing the best machine can be a daunting task. However, by considering certain factors, you can ensure that you make an informed decision that will meet the specific requirements of your project.

First and foremost, it is essential to consider the production capacity of the concrete brick making machine. Depending on the scale of your project, you will need a machine that can produce the required number of bricks within a specified timeframe. It is important to carefully assess your production needs and choose a machine that can meet those requirements efficiently.

Another important factor to consider is the type of bricks you intend to produce. Different concrete brick making machines are designed to produce different types of bricks, such as solid bricks, hollow bricks, interlocking bricks, or paving bricks. It is important to choose a machine that is capable of producing the specific type of bricks that you require for your project.

In addition to the type of bricks, you should also consider the size and shape of the bricks that the machine can produce. Some machines are versatile and can produce a variety of brick sizes and shapes, while others are more limited in their capabilities. It is important to assess your specific needs and choose a machine that can accommodate the size and shape requirements of your project.

The power source of the concrete brick making machine is another crucial factor to consider. Some machines are powered by electricity, while others may be powered by diesel or hydraulic systems. It is important to choose a machine that is compatible with the power source available at your project site, as well as one that is cost-effective and energy-efficient.

Furthermore, it is important to consider the level of automation of the concrete brick making machine. Fully automated machines can significantly increase production efficiency and reduce labor costs. However, they may also come with a higher price tag. It is important to weigh the benefits of automation against the additional cost and choose a machine that strikes the right balance for your project.

Lastly, it is important to consider the reputation and reliability of the manufacturer of the concrete brick making machine. Choose a reputable manufacturer with a proven track record of producing high-quality machines that are durable and reliable. Reading reviews and testimonials from other customers can also help you gauge the performance of a particular machine and manufacturer.

In conclusion, selecting the best concrete brick making machine for your project requires careful consideration of various factors such as production capacity, type of bricks, size and shape capabilities, power source, level of automation, and manufacturer reputation. By taking these factors into account and conducting thorough research, you can ensure that you choose a machine that meets your specific requirements and delivers optimal performance for your project.

- Comparing Features and Specifications of Various Machines

When it comes to selecting the best concrete brick making machine for your project, it is important to carefully compare the features and specifications of various machines. With so many options available on the market, it can be overwhelming to determine which machine is the right fit for your specific needs. In this ultimate guide, we will discuss the key factors to consider when choosing a concrete brick making machine, as well as provide a comprehensive comparison of different machines to help you make an informed decision.

One of the most important factors to consider when selecting a concrete brick making machine is the production capacity. This refers to the number of bricks that the machine can produce in a given amount of time, typically measured in bricks per hour. The production capacity of a machine will depend on its size, power, and efficiency. It is essential to choose a machine with a production capacity that meets the demands of your project to ensure timely completion.

Another crucial factor to consider is the type of bricks that the machine can produce. Different machines are designed to produce different types of concrete bricks, such as solid bricks, interlocking bricks, and hollow bricks. It is important to choose a machine that can produce the specific type of bricks that you require for your project. Additionally, consider the size and shape of the bricks that the machine can produce, as this will impact the overall design and functionality of your project.

In addition to production capacity and brick type, it is important to compare the power and efficiency of different machines. The power of a concrete brick making machine is typically measured in kilowatts and will determine how quickly and effectively the machine can produce bricks. Machines with higher power ratings are generally more efficient and can produce a larger volume of bricks in a shorter amount of time. Efficiency is also an important factor to consider, as it determines the operating cost and environmental impact of the machine.

Furthermore, consider the overall quality and durability of the machine. Look for machines that are made from high-quality materials and components to ensure long-lasting performance. Check customer reviews and testimonials to get an idea of the reliability and durability of the machine. Additionally, consider the after-sales support and warranty offered by the manufacturer to ensure peace of mind and assurance of quality.

In conclusion, selecting the best concrete brick making machine for your project requires careful consideration of features and specifications. By comparing the production capacity, brick type, power, efficiency, quality, and durability of different machines, you can make an informed decision that meets your specific needs. With the right machine, you can efficiently produce high-quality concrete bricks for your project and achieve successful outcomes.

- Evaluating the Production Capacity and Efficiency of Each Machine

When it comes to selecting the best concrete brick making machine for your project, it is essential to evaluate the production capacity and efficiency of each machine. These factors play a crucial role in the overall success of your brick making project, as they directly impact the quality and quantity of bricks produced.

Production capacity refers to the amount of bricks that a machine can produce in a given period of time. It is important to consider the level of demand for bricks in your project, as well as any anticipated growth in demand in the future. Selecting a machine with a higher production capacity will allow you to meet your production goals more efficiently and effectively.

Efficiency, on the other hand, refers to the ability of a machine to produce bricks with minimal wastage of materials and resources. A high-efficiency machine will help you reduce production costs and increase overall profitability. It is important to look for features such as automatic material feeding and mixing, as well as precise mold technology, to ensure that the machine operates at optimal efficiency.

When evaluating the production capacity and efficiency of concrete brick making machines, it is also important to consider the specific requirements of your project. Factors such as the size and shape of the bricks needed, as well as any special features or finishes required, will influence the type of machine that is best suited to your needs.

In addition to production capacity and efficiency, it is also important to consider the durability and reliability of the machine. Look for machines that are made from high-quality materials and engineered to withstand the rigors of continuous use. A reliable machine will help you minimize downtime and ensure that your production schedule stays on track.

In conclusion, selecting the best concrete brick making machine for your project requires careful evaluation of the production capacity and efficiency of each machine. By considering these factors alongside other important considerations such as project requirements, durability, and reliability, you can ensure that you choose a machine that meets your needs and delivers high-quality bricks for your project.

- Making an Informed Decision for Your Concrete Brick Making Project

When embarking on a concrete brick making project, one of the most crucial decisions you will need to make is selecting the right concrete brick making machine. With a multitude of options available in the market, it can be overwhelming to choose the best one that meets your specific project requirements. To help you make an informed decision, this ultimate guide provides detailed insights on how to select the best concrete brick making machine for your project.

First and foremost, it is essential to understand the different types of concrete brick making machines available in the market. The two main types are fully automatic and semi-automatic machines. Fully automatic machines are capable of producing a large number of bricks in a short period of time with minimal human intervention. On the other hand, semi-automatic machines require more manual labor but are more cost-effective and suitable for smaller-scale projects.

Consider the production capacity of the concrete brick making machine you are looking to purchase. The production capacity is measured in the number of bricks it can produce in a given time frame, such as per hour or per day. It is important to assess your project requirements and choose a machine that can meet your production needs efficiently.

Another crucial factor to consider is the level of automation and technology incorporated in the concrete brick making machine. Modern machines come equipped with advanced features such as PLC control systems, touch screen interfaces, and automatic stacking systems. These features enhance the efficiency and precision of brick production, ultimately leading to higher-quality bricks.

The size and dimensions of the bricks that the machine can produce is also an important consideration. Ensure that the machine you choose can produce bricks in the desired size and shape that align with your project specifications. Additionally, consider the versatility of the machine in terms of producing different types of bricks, such as hollow or solid bricks, interlocking bricks, or paving blocks.

When selecting a concrete brick making machine, it is crucial to evaluate the durability and reliability of the machine. Look for machines that are constructed with high-quality materials and components to ensure longevity and minimal maintenance requirements. Check for manufacturer warranties and after-sales support to address any potential issues that may arise during operation.

Furthermore, consider the cost and budget constraints of your project when selecting a concrete brick making machine. While it may be tempting to opt for the cheapest option available, it is important to weigh the upfront cost against long-term productivity and quality. Factor in additional expenses such as installation, training, and maintenance costs to determine the overall investment.

In conclusion, selecting the best concrete brick making machine for your project requires careful consideration of various factors such as production capacity, automation level, brick size, durability, and cost. By following the guidelines outlined in this ultimate guide, you can make an informed decision that aligns with your project requirements and ensures the successful completion of your concrete brick making project.

Conclusion

In conclusion, selecting the best concrete brick making machine for your project is a crucial step towards ensuring the success of your construction endeavor. With 18 years of experience in the industry, our company has gained valuable insights and expertise that can guide you in making an informed decision. By considering factors such as production capacity, automation level, and cost-efficiency, you can choose a machine that meets your specific requirements and maximizes productivity. Remember, investing in a high-quality concrete brick making machine is not just a purchase, but an investment in the future of your project. Choose wisely, and watch your construction business flourish.