Revolutionizing Construction: The Efficiency Of An Automatic Interlocking Brick Making Machine

Are you tired of traditional construction methods that are time-consuming and labor-intensive? Look no further, as we delve into the groundbreaking technology of an automatic interlocking brick making machine that is revolutionizing the construction industry. Discover how this innovative machine is driving efficiency, reducing costs, and streamlining the building process like never before. Join us as we explore the game-changing capabilities of this cutting-edge technology and witness firsthand the future of construction.

- Introduction to Automatic Interlocking Brick Making Machines

to Automatic Interlocking Brick Making Machines

In the world of construction, efficiency is key. The faster and more cost-effective a project can be completed, the better it is for everyone involved. One revolutionary technology that is changing the game in construction is the automatic interlocking brick making machine. These machines are changing the way buildings are constructed, making the process faster, easier, and more environmentally friendly.

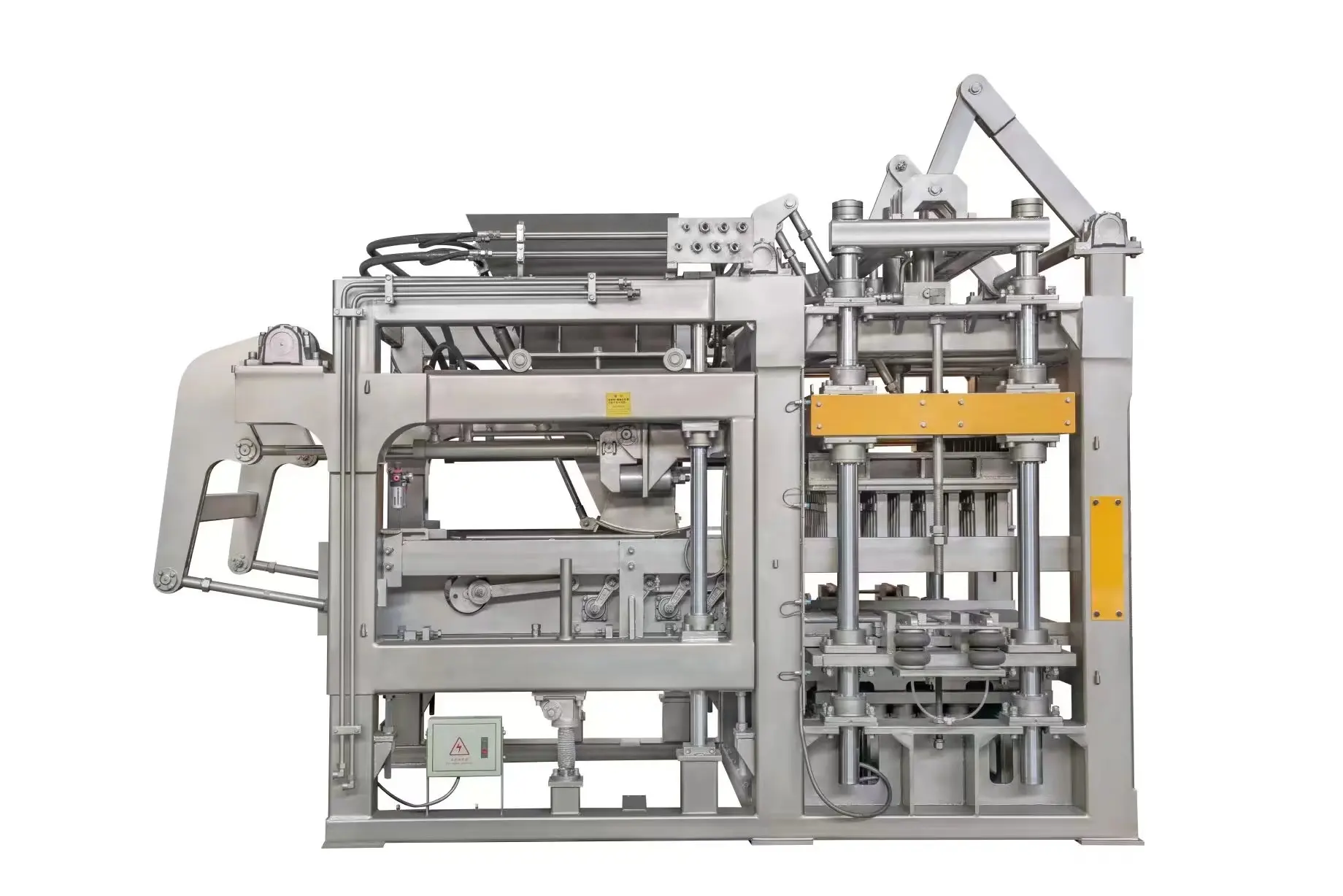

An automatic interlocking brick making machine is a type of brick making machine that uses hydraulic pressure to mold bricks from a mixture of materials. The machine is fully automated, meaning that once the raw materials are loaded into the machine, it can mold and interlock the bricks without the need for human intervention. This not only speeds up the construction process but also reduces the likelihood of errors in brick production.

One of the key advantages of automatic interlocking brick making machines is their ability to produce interlocking bricks. These bricks have grooves and ridges on their surfaces that allow them to fit together like puzzle pieces. This interlocking design adds strength to the structure, making the buildings more durable and earthquake-resistant.

Additionally, automatic interlocking brick making machines are environmentally friendly. They require less cement than traditional brick making methods, reducing carbon emissions and the environmental impact of construction projects. The use of interlocking bricks also reduces the amount of mortar needed, further decreasing the environmental footprint of the building process.

Another advantage of automatic interlocking brick making machines is their versatility. These machines can produce a wide variety of bricks, from standard bricks to specialized shapes and sizes. This allows builders to customize their projects to meet their specific needs and requirements.

In terms of efficiency, automatic interlocking brick making machines outperform traditional brick making methods. These machines can produce thousands of bricks per day, drastically reducing construction time and labor costs. The automated process also reduces the risk of injuries to workers, making construction sites safer and more efficient.

Overall, the introduction of automatic interlocking brick making machines is revolutionizing the construction industry. These machines are improving efficiency, reducing costs, and producing stronger, more environmentally friendly buildings. As technology continues to advance, the possibilities for these machines are endless, and the future of construction looks brighter than ever.

- Benefits of Utilizing Automatic Interlocking Brick Making Machines in Construction

In recent years, the construction industry has witnessed a significant transformation with the introduction of automatic interlocking brick making machines. These cutting-edge machines have revolutionized the way construction projects are completed, offering numerous benefits to contractors and homeowners alike.

First and foremost, the biggest advantage of utilizing automatic interlocking brick making machines in construction is the efficiency they provide. These machines are capable of producing a large number of high-quality interlocking bricks in a fraction of the time it would take using traditional methods. This increased efficiency not only saves time but also reduces labor costs, making construction projects more cost-effective in the long run.

Furthermore, the use of automatic interlocking brick making machines ensures consistency in the size and shape of the bricks produced. This uniformity is crucial in construction projects, as it helps to create structurally sound buildings that are less prone to cracks and other defects. Additionally, the interlocking design of these bricks makes for a stronger and more durable finished product, offering better protection against natural disasters such as earthquakes.

In addition to their efficiency and durability, automatic interlocking brick making machines also offer environmental benefits. These machines typically use locally sourced materials such as clay or soil, reducing the need for transportation and lowering the carbon footprint of construction projects. Furthermore, the interlocking design of the bricks allows for a dry stack construction method, eliminating the need for mortar and significantly reducing water usage on-site.

Another advantage of utilizing automatic interlocking brick making machines is the versatility they offer in terms of design options. These machines are capable of producing a wide variety of brick shapes, sizes, and colors, allowing for endless possibilities in architectural design. This versatility is particularly beneficial for homeowners looking to customize their homes or contractors working on unique construction projects.

Despite all these benefits, it is important to note that the initial investment in an automatic interlocking brick making machine may be higher than traditional brick-making methods. However, the long-term savings in time, labor, and materials make this investment well worth it for construction companies looking to improve efficiency and reduce costs.

In conclusion, the utilization of automatic interlocking brick making machines in construction has truly revolutionized the industry. From increased efficiency and durability to environmental benefits and design versatility, these machines offer a multitude of advantages that make them a valuable asset for any construction project. With their ability to streamline the building process and create high-quality, sustainable structures, it is clear that automatic interlocking brick making machines are the future of construction.

- How Automatic Interlocking Brick Making Machines Improve Efficiency on Construction Sites

The construction industry has seen a significant advancement in recent years with the introduction of automatic interlocking brick making machines. These innovative machines have revolutionized the way bricks are made, improving efficiency and productivity on construction sites.

One of the key benefits of automatic interlocking brick making machines is their ability to streamline the brick-making process. These machines are equipped with automated features that make it easier and faster to produce high-quality interlocking bricks. Traditional brick-making methods can be time-consuming and labor-intensive, requiring workers to manually mix and mold bricks. With automatic interlocking brick making machines, the process is automated, allowing for faster production and increased efficiency.

In addition to speeding up the brick-making process, automatic interlocking brick making machines also improve the overall quality of the bricks produced. These machines are designed to ensure consistency in size, shape, and texture, resulting in uniform and durable bricks. This is crucial in construction projects, as high-quality bricks are essential for ensuring the structural integrity and longevity of buildings.

Another advantage of automatic interlocking brick making machines is their versatility. These machines are capable of producing a variety of interlocking brick designs, allowing for flexibility in construction projects. Whether it's for paving walkways, building walls, or creating decorative elements, automatic interlocking brick making machines can cater to a wide range of construction needs.

Furthermore, automatic interlocking brick making machines are environmentally friendly. These machines use less energy and produce less waste compared to traditional brick-making methods. Additionally, interlocking bricks are known for their thermal insulation properties, which can help reduce energy consumption in buildings. By using automatic interlocking brick making machines, construction companies can reduce their environmental impact and contribute to sustainability efforts.

Overall, the adoption of automatic interlocking brick making machines has had a transformative impact on the construction industry. These machines have revolutionized the way bricks are made, improving efficiency, quality, and sustainability on construction sites. As technology continues to advance, we can expect to see even more innovative solutions that will further enhance construction processes and drive the industry forward.

- Case Studies of Successful Implementation of Automatic Interlocking Brick Making Machines

Revolutionizing Construction: The Efficiency of an Automatic Interlocking Brick Making Machine - Case Studies of Successful Implementation of Automatic Interlocking Brick Making Machines

The construction industry is constantly evolving, with new technologies and innovations shaping the way we build structures. One such innovation is the automatic interlocking brick making machine, a cutting-edge piece of equipment that has revolutionized the way bricks are produced for construction projects. In this article, we will delve into the efficiency of these machines and explore case studies of successful implementation.

Efficiency of Automatic Interlocking Brick Making Machines:

Automatic interlocking brick making machines are known for their high efficiency and productivity. These machines are able to produce a large number of bricks in a short amount of time, streamlining the construction process and reducing labor costs. The automated nature of these machines also ensures that the bricks are of consistent quality, making them ideal for construction projects that require precision and accuracy.

One of the key features of automatic interlocking brick making machines is their ability to produce interlocking bricks, which are designed to fit together like puzzle pieces. This innovative design not only enhances the aesthetic appeal of the finished structure but also increases its structural integrity, making it more resistant to earthquakes and other natural disasters.

Case Studies of Successful Implementation:

Case Study 1: Company X

Company X, a leading construction firm, recently invested in an automatic interlocking brick making machine to streamline their brick production process. The machine allowed them to significantly increase their output while reducing labor costs, ultimately leading to higher profits. The interlocking bricks produced by the machine were used in the construction of a commercial building, resulting in a structure that was not only visually appealing but also structurally sound.

Case Study 2: Construction Project Y

Construction Project Y, a government-funded initiative, utilized automatic interlocking brick making machines to construct affordable housing units for low-income families. The machines were able to produce a large number of bricks in a short amount of time, allowing the project to stay on schedule and within budget. The interlocking bricks used in the construction of the housing units were not only cost-effective but also environmentally friendly, as they required less cement and mortar compared to traditional bricks.

In conclusion, automatic interlocking brick making machines have proven to be a game-changer in the construction industry. Their efficiency, productivity, and ability to produce high-quality interlocking bricks make them a valuable asset for construction projects of all sizes. As seen in the case studies mentioned above, the successful implementation of these machines can lead to increased profits, improved structural integrity, and overall greater efficiency in the construction process.

- Future Prospects and Innovations in Automatic Interlocking Brick Making Machine Technology

In the world of construction, innovation plays a crucial role in improving efficiency and reducing costs. One such innovative technology that is making waves in the construction industry is the automatic interlocking brick making machine. This technology has the potential to revolutionize the way we build and pave the way for more sustainable and cost-effective construction practices.

The Efficiency of Automatic Interlocking Brick Making Machine

Automatic interlocking brick making machines are a game-changer in the construction industry. Traditional brick-making processes are labor-intensive and time-consuming, requiring skilled workers to manually mold each brick. However, with the introduction of automatic interlocking brick making machines, the process has been streamlined and made more efficient.

These machines are capable of producing bricks at a much faster rate than traditional methods, with some models capable of producing up to 3000 bricks per hour. This increased productivity not only saves time but also reduces labor costs, making construction projects more cost-effective.

In addition to their speed and efficiency, automatic interlocking brick making machines also produce bricks of consistent quality. This ensures that all bricks used in a construction project have the same dimensions and strength, leading to a more uniform and structurally sound building.

Future Prospects and Innovations in Automatic Interlocking Brick Making Machine Technology

As technology continues to advance, the future prospects for automatic interlocking brick making machines are promising. Innovations in machine design and materials are constantly being developed to further improve their efficiency and versatility.

One area of innovation is the development of more environmentally friendly materials for brick production. Traditional brick-making processes often use clay as a primary material, which can deplete natural resources and harm the environment. By using alternative materials such as recycled plastics or fly ash, automatic interlocking brick making machines can produce bricks that are more sustainable and eco-friendly.

Another area of innovation is the integration of smart technology into automatic interlocking brick making machines. By incorporating sensors and automated controls, these machines can optimize their production processes and reduce waste. This not only improves efficiency but also helps to minimize the environmental impact of brick production.

In conclusion, automatic interlocking brick making machines are revolutionizing the construction industry by improving efficiency, reducing costs, and promoting sustainability. With continued innovation and advancements in technology, the future prospects for this technology are bright. As construction practices continue to evolve, automatic interlocking brick making machines will undoubtedly play a key role in shaping the buildings of tomorrow.

Conclusion

In conclusion, the use of an automatic interlocking brick making machine has truly revolutionized the construction industry. With 18 years of experience in the field, our company has witnessed firsthand the efficiency and effectiveness of this technology in streamlining the brick-making process. By automating tasks that were once done manually, such as mixing, molding, and curing, we have been able to increase productivity, reduce labor costs, and produce high-quality bricks consistently. As we look towards the future, we are excited to continue pushing the boundaries of innovation and further enhance the efficiency of construction processes. With the help of advanced technologies like the automatic interlocking brick making machine, the possibilities for the industry are endless.