Revolutionizing Construction: The Impact Of Brick Machines On Building Industry

Innovation in the construction industry has always been a driving force behind quality, efficiency, and cost-effectiveness. The advent of brick machines has not only revolutionized the way buildings are constructed but has also significantly impacted the entire building industry. In this article, we will explore the profound impact that brick machines have had on construction practices and how they are shaping the future of the industry. Join us as we delve into the transformative technology that is changing the landscape of construction.

- Advancements in Construction Technology: The Rise of Brick Machines

Advancements in Construction Technology: The Rise of Brick Machines

The construction industry has seen a significant evolution over the years, with advancements in technology revolutionizing the way buildings are designed and constructed. One such advancement that has been making waves in the industry is the rise of brick machines. These innovative machines have been changing the game for the building industry, offering a more efficient and cost-effective way to produce bricks for construction projects.

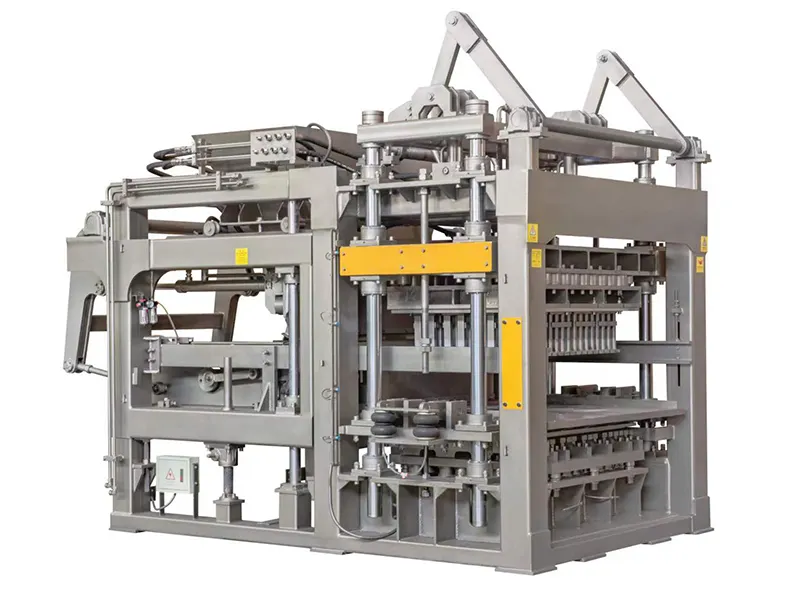

Brick machines, also known as brick making machines, are automated devices that are designed to mold clay or cement into bricks of various shapes and sizes. These machines have been around for decades, but recent advancements in technology have made them more sophisticated and versatile than ever before. Today, brick machines come in a variety of models, each with its own unique features and capabilities.

One of the key benefits of using brick machines in construction is their ability to produce bricks at a much faster rate than traditional methods. Manual brick making is a time-consuming and labor-intensive process that requires a skilled workforce to mold, shape, and dry the bricks. Brick machines automate this process, allowing for a continuous production of bricks without the need for human intervention. This not only speeds up the construction process but also ensures a consistent quality of bricks.

In addition to speed, brick machines also offer cost savings for construction projects. By eliminating the need for manual labor, brick machines reduce labor costs and increase efficiency. Moreover, the use of automated machines leads to a reduction in material wastage, further driving down construction costs. This cost-effectiveness has made brick machines an attractive option for builders and contractors looking to streamline their operations.

Furthermore, brick machines are environmentally friendly, as they reduce the carbon footprint associated with traditional brick manufacturing processes. By using automated machines, construction companies can minimize the amount of energy and resources required to produce bricks, ultimately leading to a more sustainable building industry.

The versatility of brick machines also gives builders the flexibility to create bricks for different types of construction projects. Whether it's for residential homes, commercial buildings, or infrastructure projects, brick machines can be adjusted to produce bricks of various sizes, shapes, and colors to meet the specific requirements of each project.

In conclusion, the rise of brick machines in the construction industry is revolutionizing the way buildings are constructed. With their speed, cost-effectiveness, environmental benefits, and versatility, these machines have become an indispensable tool for modern builders and contractors. As technology continues to advance, we can expect to see even more innovations in brick machine technology, further shaping the future of the building industry.

- Efficiency and Cost Savings: How Brick Machines Are Changing the Building Industry

Brick machines are becoming increasingly popular in the building industry due to their efficiency and cost-saving benefits. These machines have revolutionized construction by streamlining the brick-making process and reducing labor costs.

One of the key advantages of using a brick machine is that it significantly speeds up the brick-making process. Traditional methods of brick-making involve manual labor and can be time-consuming. With a brick machine, bricks can be produced at a much faster rate, allowing construction projects to be completed more quickly. This efficiency not only saves time but also allows builders to meet tight deadlines and complete projects on schedule.

In addition to being more efficient, brick machines also help reduce costs associated with brick production. Labor costs can be a major expense in construction projects, but with a brick machine, less manual labor is required, resulting in lower labor costs. Furthermore, brick machines can produce bricks with greater precision and consistency, reducing waste and saving money on materials.

Another benefit of using a brick machine is the ability to customize bricks to meet specific project requirements. Brick machines come with a variety of molds that allow builders to create bricks in different sizes, shapes, and colors. This flexibility enables builders to create unique designs and patterns, adding a personalized touch to their projects.

Furthermore, brick machines are environmentally friendly and sustainable. These machines use less water and energy compared to traditional brick-making methods, reducing their carbon footprint. Additionally, the bricks produced by brick machines are high-quality and durable, ensuring that buildings constructed with these bricks will last for years to come.

Overall, brick machines are revolutionizing the building industry by providing builders with a cost-effective and efficient solution for brick production. These machines are changing the way construction projects are approached, making the process faster, more affordable, and more environmentally friendly. As the demand for sustainable and efficient building practices continues to grow, brick machines are poised to play a key role in the future of the construction industry.

- Enhancing Quality and Precision: The Impact of Brick Machines on Construction Projects

In the fast-paced world of construction, efficiency and quality are key factors in completing successful projects. The introduction of brick machines has revolutionized the building industry, leading to enhanced quality and precision in construction projects. These machines have had a significant impact on the way buildings are constructed, making the process faster, more cost-effective, and environmentally friendly.

One of the key benefits of brick machines is their ability to produce consistent, high-quality bricks. Traditional brick-making methods often result in variations in size, shape, and strength of bricks, leading to inconsistencies in the final structure. Brick machines, on the other hand, ensure uniformity in the bricks produced, leading to stronger and more durable buildings. This enhanced quality is crucial in ensuring the longevity and safety of the structure.

In addition to improving quality, brick machines have also increased the precision of construction projects. These machines are capable of producing bricks with exact dimensions, allowing for greater accuracy in the building process. This precision has enabled builders to create complex designs and intricate patterns with ease, leading to more visually appealing structures. The use of brick machines has also reduced wastage of materials, as the exact amount of bricks required can be produced, minimizing construction costs and reducing environmental impact.

Furthermore, brick machines have significantly increased the efficiency of construction projects. By automating the brick-making process, these machines can produce a large number of bricks in a short amount of time. This has shortened the overall construction timeline, allowing builders to complete projects more quickly and meet tight deadlines. The speed and efficiency of brick machines have also resulted in cost savings for construction companies, as labor costs are reduced and productivity is increased.

Another important aspect of brick machines is their contribution to sustainability in the building industry. These machines use less water and produce less waste compared to traditional brick-making methods, making them more environmentally friendly. The bricks produced by these machines are also more energy-efficient, as they provide better insulation for buildings, leading to lower energy consumption for heating and cooling. By promoting sustainable building practices, brick machines are helping to reduce the carbon footprint of the construction industry.

Overall, the impact of brick machines on the building industry cannot be overstated. From enhancing quality and precision to increasing efficiency and promoting sustainability, these machines have transformed the way buildings are constructed. As technology continues to advance, we can expect further innovations in brick-making machines that will further revolutionize the construction industry. The future of construction looks bright with the continued integration of brick machines into building projects.

- Sustainability and Environmental Benefits of Using Brick Machines

Brick machines have been revolutionizing the construction industry by offering sustainability and environmental benefits that have a significant impact on building practices. These machines have become an essential tool for builders and contractors looking to improve efficiency, reduce waste, and minimize their environmental footprint.

One of the key advantages of using brick machines is the reduction in material waste. Traditional brick-making methods often result in a significant amount of wasted materials, as bricks are manually molded and fired in kilns. Brick machines, on the other hand, use automated processes to mold bricks, resulting in a more efficient use of materials and less waste overall. This not only helps to reduce costs for builders but also minimizes the environmental impact of construction projects.

In addition to reducing material waste, brick machines also offer significant energy savings compared to traditional brick-making methods. The automated processes used in brick machines require less energy to produce bricks, making them a more sustainable choice for construction projects. This not only helps to lower the carbon footprint of building projects but also reduces the overall environmental impact of construction activities.

Furthermore, brick machines have the potential to improve the quality and durability of bricks used in construction projects. The automated processes used in these machines ensure that bricks are uniform in size and shape, resulting in stronger and more consistent building materials. This can help to improve the overall quality of construction projects and increase their longevity, leading to fewer repairs and replacements in the future.

Overall, the use of brick machines in the construction industry has the potential to revolutionize building practices by offering sustainability and environmental benefits that can have a lasting impact. By reducing material waste, saving energy, and improving the quality of building materials, these machines are helping to make construction projects more efficient and environmentally friendly. As the demand for sustainable building practices continues to grow, brick machines are poised to play a crucial role in shaping the future of the construction industry.

- Potential Challenges and Future Outlook for Brick Machine Technology in Construction Industry

Brick machine technology has been revolutionizing the construction industry with its efficiency and effectiveness. In recent years, brick machines have become an integral part of building construction, offering a range of benefits that have significantly improved the way buildings are constructed. However, as with any new technology, there are potential challenges that need to be addressed, as well as a future outlook that must be considered for the continued success of brick machines in the construction industry.

One of the key challenges facing brick machine technology is the initial investment required to purchase the equipment. While brick machines can ultimately save construction companies time and money in the long run, the upfront cost can be significant. Additionally, there is a learning curve associated with using brick machines, as workers need to be trained on how to operate them effectively. This can lead to a slowdown in construction projects as workers become familiar with the new technology.

Another potential challenge for brick machines in the construction industry is the need for regular maintenance and upkeep. Like any machinery, brick machines require ongoing maintenance to ensure they are operating at peak efficiency. This can add additional costs and time to construction projects if not properly managed.

Despite these challenges, the future outlook for brick machine technology in the construction industry is promising. As the technology continues to advance, brick machines are becoming more efficient and easier to use. This is leading to increased adoption of brick machines by construction companies looking to improve their processes and reduce costs. Additionally, as brick machine technology becomes more widely used, the cost of equipment is likely to decrease, making it more accessible to smaller construction companies.

In terms of future trends, brick machines are expected to become more environmentally friendly, with a focus on reducing waste and emissions. This could include the development of brick machines that use more sustainable materials or produce less pollution during operation. Additionally, advancements in automation and robotics could further streamline the construction process, making brick machines even more efficient and cost-effective.

Overall, brick machine technology is poised to continue revolutionizing the construction industry in the coming years. While there are challenges that need to be addressed, the future outlook for brick machines is bright, with the potential to transform the way buildings are constructed for years to come.

Conclusion

In conclusion, the impact of brick machines on the building industry cannot be understated. As technology continues to revolutionize the construction sector, these machines have become an essential tool for efficiency, cost-effectiveness, and sustainability. With 18 years of experience in the industry, we have witnessed firsthand the transformative power of brick machines in streamlining construction processes and improving overall project outcomes. As we look towards the future, it is clear that these machines will continue to play a crucial role in shaping the way we build and innovate in the industry.