The Ultimate Guide To Interlock Brick Machine Prices: What You Need To Know

Are you considering investing in an interlock brick machine but feeling overwhelmed by the prices? Look no further than our comprehensive guide on all you need to know about interlock brick machine prices. From factors determining the cost to tips on getting the best deals, we've got you covered. Let us help you make an informed decision on your next purchase.

- Understanding the Basics of Interlock Brick Machines

When it comes to building durable and visually appealing structures, interlock brick machines have become a popular choice for construction projects. These machines are designed to produce interlocking bricks, which can be used in a variety of applications such as landscaping, road construction, and housing. However, before investing in an interlock brick machine, it is important to understand the basics of how these machines work and what factors can influence their prices.

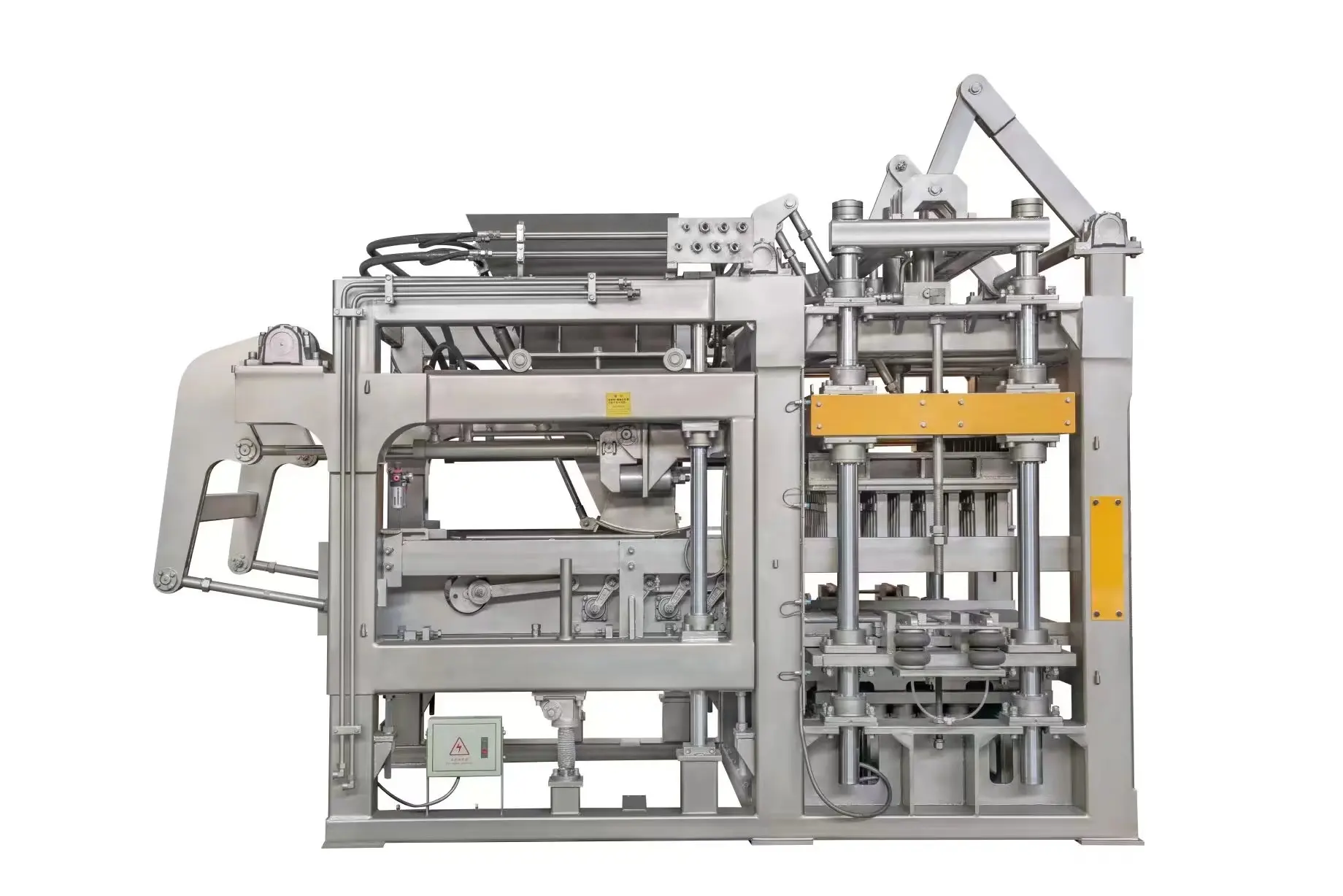

Interlock brick machines are essentially brick-making machines that are specifically designed to produce interlocking bricks. These bricks are unique in that they have a locking mechanism that allows them to fit seamlessly together, creating a strong and stable structure. The process of making interlocking bricks involves mixing raw materials such as cement, sand, and water, and then compressing the mixture into brick-shaped molds using a hydraulic press. The bricks are then left to cure and dry before being used for construction.

One of the key factors that can influence the price of an interlock brick machine is its production capacity. Machines with higher production capacities are typically more expensive, but they can also produce a larger volume of bricks in a shorter amount of time. Additionally, the quality and durability of the machine can also affect its price. Machines made with high-quality materials and advanced technology are likely to cost more upfront, but they may also last longer and require less maintenance in the long run.

Another important factor to consider when evaluating interlock brick machine prices is the level of automation and control available. Some machines come equipped with advanced features such as computerized controls, automatic brick stacking systems, and remote monitoring capabilities. While these features can increase the price of the machine, they can also improve efficiency, productivity, and overall performance.

In addition to the initial cost of the machine, it is also important to consider ongoing expenses such as maintenance, repairs, and operating costs. Some machines may require regular maintenance and servicing to ensure optimal performance, while others may have higher energy consumption or operating costs. It is important to factor in these additional costs when determining the overall value and affordability of an interlock brick machine.

Overall, understanding the basics of interlock brick machines is essential for making informed decisions about purchasing and using these machines. By considering factors such as production capacity, quality, automation, and operating costs, builders and contractors can determine the best machine for their specific needs and budget. With the right knowledge and research, investing in an interlock brick machine can lead to cost-effective and high-quality construction projects.

- Factors that Influence Interlock Brick Machine Prices

Interlocking brick machines have become a popular choice for individuals and businesses looking to produce durable and environmentally friendly bricks for construction projects. However, when it comes to purchasing these machines, there are a variety of factors that can influence the price. In this ultimate guide, we will explore the key factors that play a role in determining interlock brick machine prices.

One of the primary factors that can affect the price of an interlock brick machine is the size and capacity of the machine. Larger machines with higher production capacities tend to be more expensive than smaller machines. This is because larger machines are able to produce a greater volume of bricks in a shorter amount of time, making them ideal for larger scale construction projects. Additionally, the quality of materials used in the construction of the machine can also impact the price. Machines made with higher quality materials are generally more durable and efficient, but come with a higher price tag.

Another important factor that influences interlock brick machine prices is the level of automation and technology integrated into the machine. More advanced machines that feature automated processes, such as automatic feeding and brick stacking, are typically more expensive than manual machines. While automated machines may come with a higher upfront cost, they can ultimately save time and labor costs in the long run, making them a worthwhile investment for businesses looking to increase efficiency and productivity.

The brand and reputation of the manufacturer can also play a significant role in determining the price of an interlock brick machine. Well-known and established manufacturers with a history of producing high-quality machines may charge higher prices for their products. However, investing in a machine from a reputable manufacturer can provide peace of mind in terms of reliability and performance.

Additionally, factors such as location and market demand can impact the cost of interlock brick machines. Machines that are manufactured in countries with lower labor and production costs may be priced lower than machines produced in countries with higher overhead expenses. Furthermore, fluctuations in market demand for interlock brick machines can also influence prices, with machines being more expensive during peak construction seasons.

In conclusion, when considering purchasing an interlock brick machine, it is important to take into account the various factors that can influence the price. By understanding the key factors such as machine size, automation level, brand reputation, and market demand, individuals and businesses can make informed decisions and choose the right machine that meets their needs and budget. Ultimately, investing in a high-quality interlock brick machine can lead to cost savings, increased productivity, and high-quality brick production for construction projects.

- Comparing Different Types of Interlock Brick Machines

When it comes to building structures that are durable, sustainable, and visually appealing, interlock bricks have become a popular choice for many builders and homeowners. These bricks are known for their unique design that allows them to fit together like puzzle pieces, creating a strong and sturdy wall or pavement. However, in order to create these interlock bricks, one must invest in the right equipment - an interlock brick machine.

Interlock brick machines come in a variety of types, each with its own set of features and capabilities. In this article, we will be comparing different types of interlock brick machines in terms of their prices, to help you make an informed decision when investing in this crucial piece of equipment.

The prices of interlock brick machines can vary greatly depending on the type, brand, and features of the machine. Some of the common types of interlock brick machines include manual, semi-automatic, and fully automatic machines. Manual machines are the most basic and affordable option, requiring manual labor to operate and produce bricks. These machines are ideal for small-scale projects or for those on a tight budget.

Semi-automatic machines are a step up from manual machines, offering some automation in the brick-making process. These machines are more efficient and can produce a higher volume of bricks in a shorter amount of time. However, they still require some manual labor to operate and maintain.

Fully automatic machines are the most advanced and expensive option when it comes to interlock brick machines. These machines are completely automated, requiring minimal human intervention to produce high-quality bricks. They are ideal for large-scale projects or businesses that require a high volume of bricks to be produced on a consistent basis.

When comparing the prices of these different types of interlock brick machines, it is important to consider not only the initial cost of the machine but also the long-term maintenance and operating costs. Fully automatic machines may have a higher upfront cost, but they can save you time and labor costs in the long run. On the other hand, manual machines may be more affordable initially, but they can be labor-intensive and less efficient in the long term.

In conclusion, when it comes to choosing the right interlock brick machine for your project, it is important to consider your budget, the scale of your project, and your long-term goals. By comparing the prices of different types of interlock brick machines, you can make an informed decision that will help you achieve the desired results within your budget constraints. So, whether you opt for a manual, semi-automatic, or fully automatic machine, investing in the right interlock brick machine is essential for a successful and cost-effective construction project.

- Tips for Finding the Best Deal on an Interlock Brick Machine

Interlock brick machines have become increasingly popular in the construction industry due to their ability to produce strong and durable bricks that interlock together without the need for mortar. However, with the growing demand for these machines, it can be challenging to find the best deal on an interlock brick machine. In this ultimate guide, we will provide you with valuable tips for finding the best deal on an interlock brick machine.

When it comes to purchasing an interlock brick machine, price is a significant factor to consider. The cost of these machines can vary depending on various factors such as the brand, model, capacity, and features. It is essential to do thorough research and compare prices from different manufacturers to ensure you are getting the best deal.

One tip for finding the best deal on an interlock brick machine is to consider buying a used or refurbished machine. While new machines may come with a higher price tag, used or refurbished machines can offer significant cost savings without compromising on quality. Be sure to inspect the machine thoroughly and request maintenance records before making a purchase.

Another tip for finding the best deal on an interlock brick machine is to explore different suppliers and manufacturers. Compare prices, features, and warranties offered by different companies to determine which one offers the best value for your money. Additionally, consider reaching out to local suppliers or manufacturers to inquire about any discounts or promotions they may have available.

It is also essential to consider the capacity and output of the interlock brick machine when determining the price. Machines with higher capacities and output levels may come with a higher price tag but can increase productivity and efficiency in the long run. Evaluate your specific needs and budget to determine the right machine for your requirements.

In addition to comparing prices, it is crucial to consider the quality and reliability of the interlock brick machine. Look for machines that are built with high-quality materials and components to ensure durability and long-term performance. Check customer reviews and testimonials to gauge the reputation of the manufacturer and the quality of their products.

Lastly, consider the after-sales support and warranty offered by the manufacturer when purchasing an interlock brick machine. A reliable manufacturer should provide excellent customer service, technical support, and warranty coverage to ensure that your machine operates smoothly and efficiently. Be sure to inquire about the terms and conditions of the warranty before making a purchase.

In conclusion, finding the best deal on an interlock brick machine requires thorough research, comparison, and consideration of various factors. By following these tips and guidelines, you can make an informed decision and invest in a high-quality interlock brick machine that meets your needs and budget. Remember to prioritize quality, reliability, and after-sales support to ensure a successful purchase.

- The Importance of Quality and Reliability in Interlock Brick Machines

Interlocking brick machines have revolutionized the construction industry, providing builders with a cost-effective and efficient way to produce high-quality bricks for various construction projects. As the demand for interlock brick machines continues to rise, it is crucial for builders and contractors to understand the importance of quality and reliability when it comes to selecting the right machine for their needs.

When it comes to interlock brick machine prices, there are several factors to consider. Quality and reliability are two of the most important factors to take into account when evaluating the price of a machine. A high-quality machine will produce consistent and durable interlock bricks, reducing the need for costly repairs and maintenance down the line. Additionally, a reliable machine will ensure that construction projects are completed on time and within budget.

It is essential to thoroughly research and compare different interlock brick machines to find the best price for your specific needs. Look for machines that are made from high-quality materials and have a proven track record of reliability. While it may be tempting to opt for a cheaper machine, it is important to remember that investing in a high-quality and reliable interlock brick machine will ultimately save you time and money in the long run.

In addition to quality and reliability, it is also important to consider the features and capabilities of the interlock brick machine. Some machines may have advanced features such as automatic brick stacking and mold changing capabilities, which can greatly increase productivity and efficiency on construction sites. However, these features may come at a higher price, so it is important to weigh the costs and benefits before making a decision.

Another important factor to consider when evaluating interlock brick machine prices is the level of customer support and after-sales service provided by the manufacturer. A reliable manufacturer will offer comprehensive support and maintenance services to ensure that your machine continues to operate at peak performance for years to come. Be sure to inquire about the manufacturer's warranty and service agreements before making a purchase.

In conclusion, when it comes to interlock brick machine prices, the importance of quality and reliability cannot be overstated. Investing in a high-quality and reliable machine will not only save you time and money in the long run but will also ensure the success of your construction projects. By carefully evaluating and comparing different machines based on these factors, you can make an informed decision that will benefit your business for years to come.

Conclusion

In conclusion, understanding interlock brick machine prices is essential for anyone looking to invest in this technology. By considering factors such as machine capacity, features, and brand reputation, you can make an informed decision that meets your specific needs and budget. With 18 years of experience in the industry, our company is dedicated to providing high-quality interlock brick machines at competitive prices. Whether you are a seasoned professional or a newcomer to the industry, we are confident that our expertise and products will help you succeed in your brick-making endeavors. Thank you for reading "The Ultimate Guide to Interlock Brick Machine Prices: What You Need to Know" and we look forward to assisting you with your future projects.