The Ultimate Guide To Choosing The Best Cement Brick Machine For Your Construction Needs

Are you in the market for a cement brick machine but feeling overwhelmed by the options available? Look no further! Our comprehensive guide is here to help you make the best choice for your construction needs. From factors to consider when selecting a machine to recommendations for top brands, we've got you covered. Get ready to find the perfect cement brick machine with our ultimate guide.

- Understanding the Benefits of Using Cement Brick Machines in Construction Projects

Cement brick machines play a crucial role in construction projects, offering numerous benefits that make them an essential tool for any construction team. With advancements in technology, these machines have become more efficient and versatile, making them a popular choice for both small-scale and large-scale construction projects.

One of the main benefits of using cement brick machines in construction projects is their cost-effectiveness. These machines are designed to produce bricks at a much faster rate than traditional methods, saving both time and labor costs. Additionally, by producing bricks on-site, construction teams can reduce transportation costs and minimize the risk of damage to the bricks during transit.

Another significant advantage of cement brick machines is their ability to produce high-quality bricks with consistent sizes and shapes. This ensures that the bricks fit together perfectly, resulting in a strong and durable structure. The machines also allow for customization, with the ability to create bricks in various colors and textures to meet the specific design requirements of the project.

Furthermore, cement brick machines are environmentally friendly, as they produce minimal waste and consume less energy compared to traditional brick-making methods. By using these machines, construction teams can reduce their carbon footprint and contribute to sustainability efforts in the construction industry.

In addition to cost-effectiveness, quality, and environmental benefits, cement brick machines also offer versatility in terms of brick designs and sizes. These machines can produce a wide range of brick types, including solid bricks, hollow bricks, and interlocking bricks, allowing for creative design possibilities in construction projects.

When choosing the best cement brick machine for your construction needs, it is important to consider factors such as production capacity, size and weight of the machine, maintenance requirements, and brand reputation. By investing in a high-quality cement brick machine, construction teams can improve efficiency, reduce costs, and achieve superior results in their projects.

In conclusion, cement brick machines are essential tools for construction projects, offering a wide range of benefits that make them a valuable asset for construction teams. With their cost-effectiveness, quality, environmental friendliness, and versatility, these machines have become a popular choice for modern construction projects. By choosing the best cement brick machine for your construction needs, you can streamline your building process and achieve exceptional results in your projects.

- Factors to Consider When Choosing the Best Cement Brick Machine for Your Needs

When embarking on a construction project that requires the use of cement bricks, it is essential to choose the best cement brick machine that suits your specific needs. With a variety of options available in the market, it can be overwhelming to make a decision. In this ultimate guide, we will explore the factors to consider when selecting the best cement brick machine for your construction needs.

1. Quality and Reliability:

One of the essential factors to consider when choosing a cement brick machine is the quality and reliability of the machine. It is crucial to invest in a machine that is well-built and durable to ensure long-term functionality. Look for machines that are made from high-quality materials and have a proven track record of reliability.

2. Production Capacity:

Another important factor to consider is the production capacity of the cement brick machine. Depending on the size of your construction project, you will need a machine that can produce a sufficient amount of bricks in a timely manner. Consider the output capacity of the machine and choose one that meets your production requirements.

3. Automation and Efficiency:

In today's fast-paced construction industry, automation and efficiency are key factors to consider when choosing a cement brick machine. Look for machines that offer automation features such as automatic feeding, mixing, and brick molding to streamline the production process and increase efficiency. This will not only save time but also reduce labor costs.

4. Cost and Budget:

Cost is another crucial factor to consider when selecting a cement brick machine. It is essential to have a clear understanding of your budget constraints and compare the pricing of different machines. While it may be tempting to opt for a cheaper option, it is important to consider the overall quality and performance of the machine to ensure it meets your construction needs.

5. Maintenance and Support:

When choosing a cement brick machine, it is important to consider the maintenance and support services offered by the manufacturer. Look for machines that come with a warranty and have a reputable customer support team that can provide assistance in case of any issues. Regular maintenance is crucial to ensure the longevity and efficiency of the machine.

In conclusion, choosing the best cement brick machine for your construction needs requires careful consideration of various factors such as quality, production capacity, automation, cost, and maintenance. By taking these factors into account and conducting thorough research, you can find a machine that meets your specific requirements and helps you achieve success in your construction projects.

- Comparing Different Types of Cement Brick Machines Available in the Market

Cement brick machines are an essential piece of equipment for any construction project involving the creation of bricks or blocks. As technology continues to advance, there are now many different types of cement brick machines available in the market, each with its own unique features and capabilities. In this ultimate guide, we will compare the various types of cement brick machines to help you choose the best one for your construction needs.

One of the most common types of cement brick machines is the manual brick machine. This type of machine is operated by hand and requires a significant amount of physical labor to produce bricks. While manual brick machines are typically the most affordable option, they are also the slowest and least efficient in terms of production speed. However, for small-scale construction projects or for those on a tight budget, a manual brick machine may be sufficient.

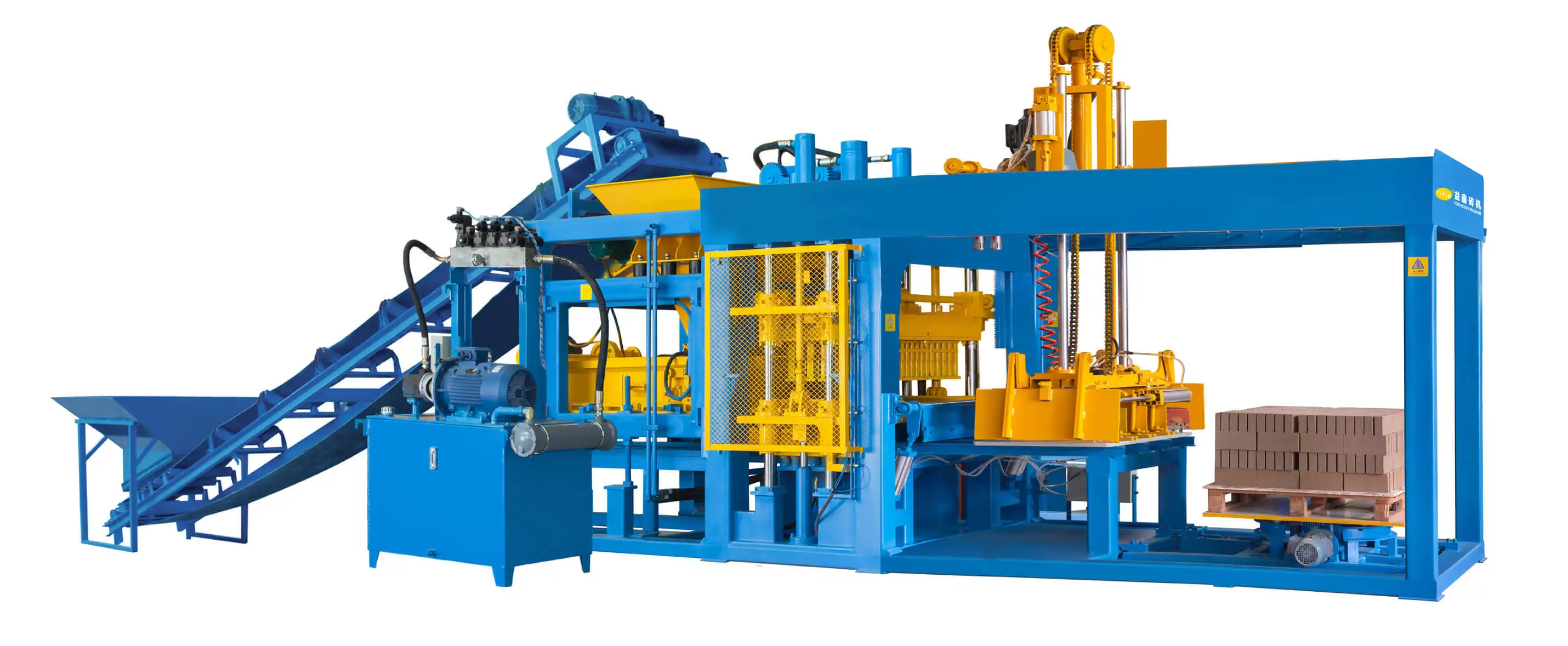

On the other end of the spectrum are fully automatic cement brick machines. These machines require minimal human intervention and can produce a large number of bricks in a short amount of time. Fully automatic cement brick machines are highly efficient and are ideal for large-scale construction projects where speed and productivity are important. However, these machines also come with a higher price tag and may require more maintenance and upkeep.

In between manual and fully automatic cement brick machines are semi-automatic brick machines. These machines combine the efficiency of automatic machines with the affordability of manual machines. Semi-automatic machines require some manual labor, such as loading and unloading materials, but the actual brick-making process is automated. This type of machine is a good compromise for those looking for a balance between speed, efficiency, and cost.

Another important factor to consider when choosing a cement brick machine is the size and capacity of the machine. Machines come in a range of sizes, from small, portable machines suitable for DIY projects to large industrial machines capable of producing thousands of bricks per day. It is important to determine the amount of bricks you need to produce and choose a machine that can meet your production requirements.

Additionally, when comparing cement brick machines, it is important to consider the quality and type of bricks they are capable of producing. Some machines are designed for specific types of bricks, such as solid bricks, hollow bricks, or interlocking bricks. It is important to choose a machine that can produce the type of bricks needed for your construction project.

In conclusion, choosing the best cement brick machine for your construction needs involves considering a variety of factors, including the type of machine, size and capacity, and the quality of bricks produced. By carefully comparing the different types of cement brick machines available in the market, you can select a machine that meets your specific requirements and helps you achieve your construction goals efficiently and effectively.

- Key Features to Look for in a High-Quality Cement Brick Machine

When it comes to construction projects, choosing the right machinery is crucial for ensuring the success of the project. One key piece of equipment that is essential for any construction project is a cement brick machine. These machines are used to produce high-quality cement bricks which are an integral part of any building structure. But with so many options available in the market, it can be overwhelming to choose the best one for your needs. In this guide, we will explore the key features to look for in a high-quality cement brick machine to help you make an informed decision.

1. Production Capacity:

One of the most important features to consider when choosing a cement brick machine is its production capacity. The production capacity of a machine determines how many bricks it can produce in a specific period of time. It is important to assess your construction needs and choose a machine that can meet those requirements. Look for a machine that has a high production capacity to ensure that you can meet project deadlines efficiently.

2. Automation Level:

Another important feature to consider is the automation level of the cement brick machine. Fully automated machines are more efficient and require less manual labor, which can save both time and money. Look for a machine that offers features such as automatic mixing, molding, and brick stacking to streamline the production process and improve productivity.

3. Durability and Reliability:

Durability and reliability are crucial factors to consider when choosing a cement brick machine. Construction sites can be tough environments, so it is important to choose a machine that is built to withstand heavy use and harsh conditions. Look for machines that are made from high-quality materials and are designed to last for a long time. A reliable machine will ensure smooth operation and minimize downtime, saving you both time and money in the long run.

4. Energy Efficiency:

Energy efficiency is another important feature to look for in a cement brick machine. Machines that are energy-efficient can help reduce operating costs and minimize environmental impact. Look for machines that are equipped with energy-saving features such as variable speed drives and automatic power-off functions to optimize energy consumption.

5. Versatility:

Lastly, consider the versatility of the cement brick machine. A versatile machine can produce a wide range of brick sizes and shapes, allowing you to customize your bricks to meet specific design needs. Look for machines that offer flexibility in terms of mold options and brick configurations to maximize the potential of your machine.

In conclusion, choosing the best cement brick machine for your construction needs involves considering a number of key features. By carefully assessing factors such as production capacity, automation level, durability, energy efficiency, and versatility, you can select a high-quality machine that will meet your needs and help you achieve success in your construction projects. Remember to prioritize quality and reliability when making your decision and invest in a machine that will deliver long-lasting performance and value.

- Tips for Maximizing Efficiency and Productivity with Your Chosen Cement Brick Machine

Choosing the best cement brick machine for your construction needs is a crucial decision that can have a significant impact on the efficiency and productivity of your projects. In this ultimate guide, we will provide you with essential tips for maximizing efficiency and productivity with your chosen cement brick machine.

When it comes to selecting a cement brick machine, there are several factors to consider. The most important factor is to determine the type and size of bricks you need for your project. Different cement brick machines are designed to produce different sizes and types of bricks, so it is essential to choose a machine that can meet your specific requirements.

Another crucial factor to consider is the production capacity of the cement brick machine. The production capacity of a machine is measured in bricks per hour, and it is essential to choose a machine that can meet the demands of your project. If you have a large-scale project, you will need a high-capacity machine to ensure that you can produce enough bricks to meet your deadlines.

In addition to production capacity, it is also important to consider the reliability and durability of the cement brick machine. A reliable and durable machine will minimize downtime and maintenance costs, allowing you to maximize your efficiency and productivity. Look for machines from reputable manufacturers with a track record of producing high-quality and reliable equipment.

Furthermore, it is crucial to consider the ease of operation and maintenance of the cement brick machine. A machine that is easy to operate and maintain will allow you to save time and resources, enabling you to focus on other aspects of your project. Look for machines with user-friendly interfaces and easy access to maintenance components.

Additionally, consider the energy efficiency of the cement brick machine. Energy-efficient machines will not only help you reduce your operating costs but also minimize your environmental impact. Look for machines with energy-saving features, such as automatic shut-off functions and energy-efficient motors.

Lastly, consider the cost of the cement brick machine. While it is essential to choose a machine that meets your production requirements, it is also important to consider your budget. Compare prices from different manufacturers and suppliers to find a machine that offers the best value for your money.

In conclusion, choosing the best cement brick machine for your construction needs is a crucial decision that can have a significant impact on the efficiency and productivity of your projects. By considering factors such as production capacity, reliability, ease of operation, energy efficiency, and cost, you can maximize efficiency and productivity with your chosen cement brick machine.

Conclusion

In conclusion, after delving into the intricacies of selecting the best cement brick machine for your construction needs, it is evident that thorough research and consideration of various factors are crucial. With our 18 years of experience in the industry, we at [Company Name] have the knowledge and expertise to guide you in making the right decision. By choosing a cement brick machine that aligns with your specific requirements and budget, you can ensure efficient and cost-effective construction processes. Trust in our experience and let us help you find the perfect machine to elevate your construction projects to new heights. Choose wisely, choose [Company Name].