The Advantages Of Using An Interlock Brick Machine In Construction Projects

Are you looking to revolutionize your construction projects with cutting-edge technology? Look no further than the interlock brick machine. In this article, we will explore the numerous advantages of using this innovative machine in construction projects. From cost savings to increased efficiency, the interlock brick machine is sure to take your projects to the next level. Read on to discover how this technology can benefit your construction endeavors.

- Understanding Interlock Brick Machines and How They Work

Interlock brick machines have revolutionized the construction industry by providing a cost-effective and efficient way to produce interlocking bricks for various construction projects. Understanding how these machines work is essential for anyone looking to take advantage of their numerous benefits in construction projects.

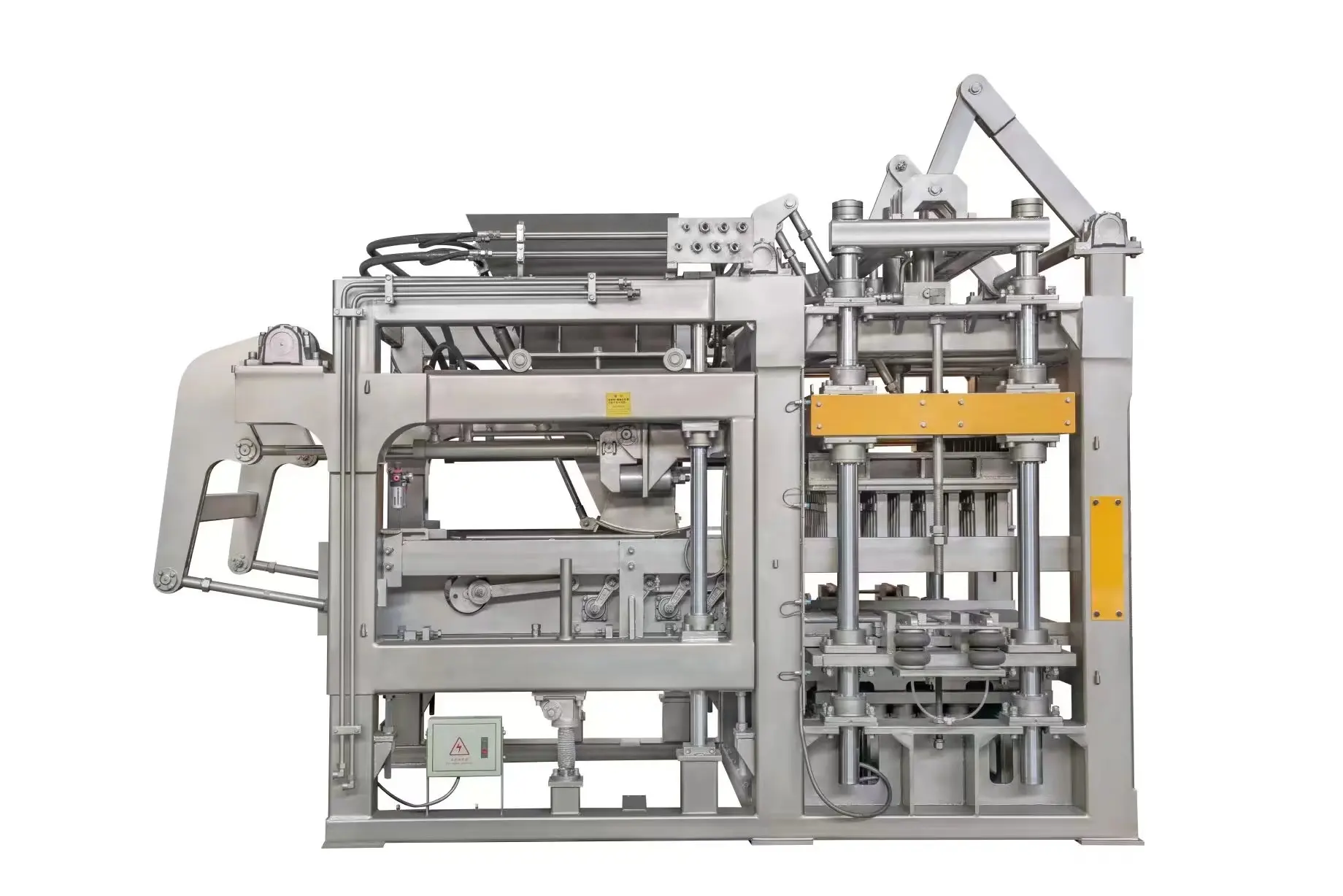

Interlock brick machines are designed to compress and form bricks using a combination of raw materials such as clay, soil, sand, cement, and water. These machines come in various sizes and capacities, ranging from small manual machines suitable for personal use to large automated machines for commercial production.

The process begins by preparing the raw materials, which are then mixed together to create a homogenous mixture. This mixture is then fed into the machine, where it is compressed and shaped into bricks using molds designed to create interlocking patterns. The bricks are then cured and dried before they are ready to be used in construction projects.

One of the main advantages of using interlock brick machines is their versatility. These machines can be used to produce a wide range of brick sizes, shapes, and patterns, making them suitable for various construction applications. Interlocking bricks are known for their strength and durability, making them ideal for building structures that require high load-bearing capacity.

Another key advantage of using interlock brick machines is their cost-effectiveness. By producing bricks on-site, construction companies can save on transportation costs and reduce waste generated during the construction process. Additionally, interlocking bricks require less mortar for installation, further reducing construction costs.

In addition to being cost-effective, interlock brick machines are also environmentally friendly. The production process of interlocking bricks requires less energy and water compared to traditional brick-making methods. Additionally, interlocking bricks can be recycled and reused, further reducing the environmental impact of construction projects.

Furthermore, interlock brick machines are easy to operate and maintain, making them suitable for both small-scale and large-scale construction projects. With proper training and maintenance, these machines can produce high-quality bricks consistently, ensuring the success of construction projects.

In conclusion, interlock brick machines offer numerous advantages for construction projects, including cost-effectiveness, versatility, durability, and environmental sustainability. Understanding how these machines work is essential for anyone looking to leverage their benefits in construction projects. By investing in an interlock brick machine, construction companies can streamline their production process, reduce costs, and contribute to sustainable construction practices.

- Cost and Time Efficiency of Using Interlock Brick Machines

Interlock brick machines have revolutionized the construction industry, offering unparalleled cost and time efficiency for construction projects. These machines allow for the quick and easy production of interlocking bricks, which can be used for a variety of building purposes, from residential homes to commercial buildings.

One of the key advantages of using an interlock brick machine is the significant cost savings it offers. Traditional bricks can be expensive to purchase and transport, while interlocking bricks can be produced on-site using the machine. This eliminates the need for transportation costs and reduces the overall cost of the project. Additionally, interlocking bricks are typically made from locally sourced materials, further reducing costs and minimizing environmental impact.

In addition to cost savings, interlock brick machines also offer significant time efficiency benefits. Traditional bricklaying can be a time-consuming process, requiring skilled labor and precise measurements. With an interlock brick machine, bricks can be produced quickly and easily, allowing for rapid construction progress. The interlocking design of the bricks also simplifies the installation process, saving time and reducing the need for additional labor.

Another advantage of using an interlock brick machine is the versatility it offers in construction projects. Interlocking bricks can be used for a wide range of building applications, including walls, pavements, and even landscaping features. The modular design of the bricks allows for easy customization and flexibility in design, making them ideal for projects of all sizes and complexities.

In addition to cost and time efficiency, interlock brick machines also offer environmental benefits. The use of locally sourced materials and on-site production reduces the carbon footprint of construction projects, while the interlocking design of the bricks minimizes waste and promotes sustainable building practices.

Overall, the use of an interlock brick machine in construction projects offers a wide range of advantages, including cost and time efficiency, versatility, and environmental benefits. By investing in this cutting-edge technology, builders and contractors can streamline their construction processes, reduce costs, and create sustainable, high-quality structures.

- Durability and Strength of Interlock Bricks in Construction

Interlock bricks have become a popular choice in construction projects due to their durability and strength. The use of an interlock brick machine in producing these bricks has further enhanced their advantages in the construction industry.

One of the main advantages of using an interlock brick machine is the strength and durability of the bricks produced. The machine applies high pressure to the raw materials, such as sand, cement, and water, to create interlocking bricks that are solid and resistant to wear and tear. This strength and durability make interlock bricks ideal for various construction projects, including driveways, pathways, and even building structures.

In addition to their strength, interlock bricks produced by the machine are also known for their interlocking design. This design allows the bricks to fit together seamlessly, creating a strong bond that adds to the overall stability of the structure. The interlocking feature also eliminates the need for mortar, making the construction process faster and more cost-effective.

Furthermore, interlock bricks produced by the machine come in a variety of shapes and sizes, allowing for creative and versatile designs in construction projects. From standard rectangular bricks to curved and angled bricks, the possibilities are endless with an interlock brick machine. This flexibility in design not only adds to the aesthetic appeal of the structure but also increases its functionality and practicality.

Another advantage of using an interlock brick machine is its efficiency in production. The machine is capable of producing a large number of bricks in a short amount of time, allowing construction projects to progress quickly and efficiently. This can lead to cost savings, as the construction process is completed faster, and fewer materials are wasted.

In terms of sustainability, interlock bricks produced by the machine are environmentally friendly. The process of making interlock bricks requires less cement than traditional bricks, reducing carbon emissions and energy consumption. Additionally, the interlocking design of the bricks allows for better water drainage, preventing waterlogging and reducing the risk of mold and mildew.

Overall, the advantages of using an interlock brick machine in construction projects are clear. From their strength and durability to their creative design possibilities and production efficiency, interlock bricks produced by the machine are a valuable asset to any construction project. As the demand for sustainable and cost-effective building materials continues to grow, the use of an interlock brick machine is a wise choice for builders and contractors alike.

- Versatility and Design Options Offered by Interlock Brick Machines

Interlock brick machines have revolutionized the construction industry with their versatility and numerous design options. These machines are a game-changer for construction projects, offering a wide range of advantages that make them a preferred choice for builders and contractors.

One of the key advantages of using an interlock brick machine is the ease of operation. These machines are designed to be user-friendly, making it easy for even novice operators to produce high-quality interlocking bricks. The process is straightforward and efficient, with minimal training required to operate the machine effectively. This simplicity saves time and money, as builders can quickly produce the bricks they need on-site without the need for outsourcing.

In addition to their ease of operation, interlock brick machines offer a wide variety of design options. Builders can create custom patterns and designs by simply adjusting the settings on the machine. This flexibility allows for endless possibilities, from simple straight lines to intricate designs that add a touch of elegance to any project. Whether you're looking to create a classic look or a modern design, an interlock brick machine can help you achieve the perfect aesthetic for your construction project.

Furthermore, interlock brick machines are known for their durability and strength. Interlocking bricks are designed to withstand the elements, making them an ideal choice for outdoor applications such as driveways, walkways, and patios. These bricks are also resistant to cracking and shifting, ensuring a long-lasting and maintenance-free surface for years to come.

Another advantage of using an interlock brick machine is the cost savings. By producing interlocking bricks on-site, builders can save money on transportation and labor costs. Additionally, interlocking bricks are made from locally-sourced materials, reducing the environmental impact of construction projects. This eco-friendly approach is not only cost-effective but also helps to reduce the carbon footprint of a building project.

Overall, the advantages of using an interlock brick machine in construction projects are clear. These machines offer versatility, design options, durability, and cost savings that make them a smart choice for builders and contractors. Whether you're looking to create a stunning outdoor space or a durable driveway, an interlock brick machine can help you achieve your construction goals with ease.

- Environmental Benefits of Using Interlock Brick Machines in Construction

Interlock brick machines have revolutionized the construction industry by offering a more sustainable and environmentally friendly alternative to traditional construction methods. These machines produce interlocking bricks that fit together like puzzle pieces, eliminating the need for mortar and drastically reducing construction waste. The environmental benefits of using interlock brick machines in construction projects are numerous and significant.

One of the primary environmental advantages of interlock brick machines is the reduction in carbon footprint. Traditional brick making processes involve the burning of clay bricks in kilns, which releases harmful greenhouse gases into the atmosphere. In contrast, interlock brick machines utilize a hydraulic press to compress a mixture of soil, cement, and water into bricks, eliminating the need for kiln firing. This significantly reduces carbon emissions and helps combat climate change.

Furthermore, interlock bricks are more energy-efficient to produce compared to traditional bricks. The hydraulic press used in interlock brick machines requires less energy than kiln firing, resulting in lower energy consumption and reduced reliance on non-renewable resources. This energy efficiency not only lowers production costs but also contributes to a more sustainable construction industry.

In addition to being energy-efficient, interlock brick machines also help reduce construction waste. Traditional bricklaying methods often result in excess mortar and brick pieces that are discarded as waste. Interlock bricks, on the other hand, fit together seamlessly without the need for mortar, reducing waste generated during construction. This not only saves money on disposal costs but also minimizes the environmental impact of construction projects.

Another environmental benefit of using interlock brick machines is water conservation. Traditional brick making processes require significant amounts of water for mixing, molding, and curing the bricks. In contrast, interlock brick machines use a more precise amount of water to produce bricks, minimizing water usage and reducing overall water consumption in construction projects. This is particularly important in regions experiencing water scarcity, where sustainable water management practices are essential.

Overall, the environmental benefits of using interlock brick machines in construction projects are clear. From reducing carbon emissions and energy consumption to minimizing construction waste and conserving water, these machines offer a more sustainable and eco-friendly alternative to traditional brick making processes. As the construction industry continues to prioritize sustainability, interlock brick machines are poised to play a crucial role in shaping the future of construction.

Conclusion

In conclusion, the advantages of using an interlock brick machine in construction projects are undeniable. With 18 years of experience in the industry, our company has seen firsthand the transformation that these machines bring to construction projects. From increased efficiency and cost savings to durable and visually appealing results, the benefits are clear. By investing in an interlock brick machine, construction companies can elevate their projects to new heights and set themselves apart from the competition. With the right tools and the right technology, the possibilities are endless. Choose innovation, choose success – choose an interlock brick machine for your next construction project.