Revolutionizing Construction: The Power Of Cement Bricks Hydraulic Machines

Are you ready to revolutionize the construction industry? Discover the incredible power of cement bricks hydraulic machines in our latest article. Learn how this innovative technology is transforming the way we build, offering faster production, higher quality materials, and more sustainable construction practices. Join us as we explore the endless possibilities of hydraulic machines and their potential to reshape the future of construction.

- The Evolution of Cement Bricks Production Methods

The Evolution of Cement Bricks Production Methods

Over the past few decades, the construction industry has seen a significant evolution in the way cement bricks are produced. The traditional methods of manually making bricks have now been replaced by advanced technology, specifically the use of cement bricks hydraulic machines. These powerful machines have revolutionized the production of cement bricks, making the process faster, more efficient, and more environmentally friendly.

One of the key advantages of using cement bricks hydraulic machines is the speed at which they can produce bricks. Traditional brick-making methods required hours of manual labor to mix the right ratio of materials, mold the bricks, and allow them to dry. With hydraulic machines, this process is automated, significantly reducing the amount of time it takes to produce a large number of bricks. This increase in production speed has allowed construction companies to meet tight deadlines and complete projects in a fraction of the time it would have taken using traditional methods.

In addition to speed, cement bricks hydraulic machines also offer improved efficiency in the production process. These machines are able to mix the cement, sand, and water to create the perfect consistency for the bricks, ensuring that each brick is uniform in size and strength. This level of precision is difficult to achieve with manual methods and results in a higher quality finished product. Furthermore, hydraulic machines are able to compress the mixture at high pressure, creating bricks that are more durable and long-lasting than those made by hand.

Another significant benefit of using cement bricks hydraulic machines is their environmental impact. Traditional brick-making methods require the burning of large amounts of wood or coal to fire the bricks in kilns, releasing harmful emissions into the atmosphere. Hydraulic machines, on the other hand, do not require any firing process, reducing the carbon footprint of brick production. Additionally, the automated nature of these machines means that there is less waste generated during the production process, further minimizing the environmental impact of brick-making.

Overall, the evolution of cement bricks production methods, specifically the introduction of hydraulic machines, has had a profound impact on the construction industry. These machines have not only increased production speed and efficiency but have also improved the quality of cement bricks and reduced the environmental impact of their production. As technology continues to advance, it is likely that we will see even more innovations in the way bricks are made, further revolutionizing the construction industry.

- How Hydraulic Machines Are Transforming the Construction Industry

In the world of construction, technology plays a vital role in revolutionizing the way projects are completed. One such technology that is transforming the construction industry is the cement bricks hydraulic machine. These powerful machines are changing the way cement bricks are made and are significantly improving efficiency on construction sites.

Hydraulic machines are known for their ability to utilize fluid power to perform various tasks, and when it comes to the construction industry, they are proving to be invaluable. The use of hydraulic machines in the production of cement bricks has resulted in faster production times, reduced labor costs, and improved overall quality of the bricks.

One of the key advantages of using hydraulic machines for cement brick production is their ability to exert high levels of pressure, resulting in stronger and more durable bricks. By applying precise pressure to the cement mixture, hydraulic machines are able to create bricks that are uniform in shape and size, reducing the need for manual labor and minimizing waste. This not only saves time and money but also ensures that the bricks produced are of the highest quality.

Another benefit of utilizing hydraulic machines in the construction industry is their versatility. These machines can be easily adjusted to accommodate different types of cement mixtures, allowing for a variety of brick designs to be produced. Whether it's standard rectangular bricks or custom-shaped bricks for specific projects, hydraulic machines can deliver consistent results with precision and efficiency.

Additionally, the use of hydraulic machines for cement brick production is also helping to reduce the environmental impact of construction projects. By optimizing the production process and minimizing waste, these machines are promoting sustainability and efficiency in the industry. With the growing emphasis on eco-friendly building practices, the adoption of hydraulic machines is a step in the right direction for ensuring that construction projects are more environmentally friendly.

Overall, the power of cement bricks hydraulic machines is undeniable. These machines are revolutionizing the construction industry by streamlining production processes, improving efficiency, and delivering high-quality bricks for various projects. As technology continues to advance, the use of hydraulic machines in construction is expected to become even more prevalent, further transforming the way buildings are constructed. With their versatility, precision, and environmentally friendly benefits, hydraulic machines are truly a game-changer in the construction industry.

- Advantages of Using Cement Bricks Hydraulic Machines

In the world of construction, there has been a major shift towards using cement bricks hydraulic machines to streamline the building process and increase efficiency. These innovative machines have revolutionized the way buildings are constructed, offering a wide range of advantages that make them a must-have tool for any construction project.

One of the key advantages of using cement bricks hydraulic machines is their ability to produce high-quality bricks at a rapid pace. These machines are equipped with powerful hydraulic systems that exert immense pressure on the raw materials, resulting in bricks that are strong, durable, and uniform in shape. This level of precision and consistency cannot be achieved by traditional brick-making methods, making cement bricks hydraulic machines the go-to choice for builders who prioritize quality and efficiency.

Another major advantage of these machines is their versatility. They can be used to produce a variety of brick sizes and shapes, allowing builders to customize their designs and meet specific project requirements. Whether it’s for a residential, commercial, or industrial project, cement bricks hydraulic machines can adapt to different needs and produce bricks that perfectly fit the job.

Furthermore, the use of cement bricks hydraulic machines significantly reduces manual labor and labor costs. These machines are fully automated, with minimal human intervention required during the brick-making process. This not only speeds up construction timelines but also eliminates the risk of human error, resulting in a more consistent and reliable end product.

In addition to their efficiency and cost-saving benefits, cement bricks hydraulic machines are also environmentally friendly. By using hydraulic pressure instead of traditional firing methods, these machines produce bricks that are more energy-efficient and eco-friendly. This aligns with the growing trend of sustainable construction practices, making cement bricks hydraulic machines a smart choice for environmentally conscious builders.

Overall, the advantages of using cement bricks hydraulic machines are undeniable. From their ability to produce high-quality bricks quickly and efficiently to their versatility, cost-effectiveness, and eco-friendliness, these machines are truly revolutionizing the construction industry. Builders who invest in these advanced tools will not only save time and money but also elevate the overall quality of their projects. As the demand for faster, greener, and more reliable construction methods continues to rise, it’s clear that cement bricks hydraulic machines are here to stay.

- Innovations in Design and Efficiency for Cement Brick Production

Innovations in Design and Efficiency for Cement Brick Production

The construction industry has seen a significant revolution with the introduction of cement bricks hydraulic machines. These machines have completely changed the way cement bricks are produced, making the process faster, more efficient, and more cost-effective. With innovations in design and technology, these machines are transforming the construction industry and setting new standards for efficiency and quality.

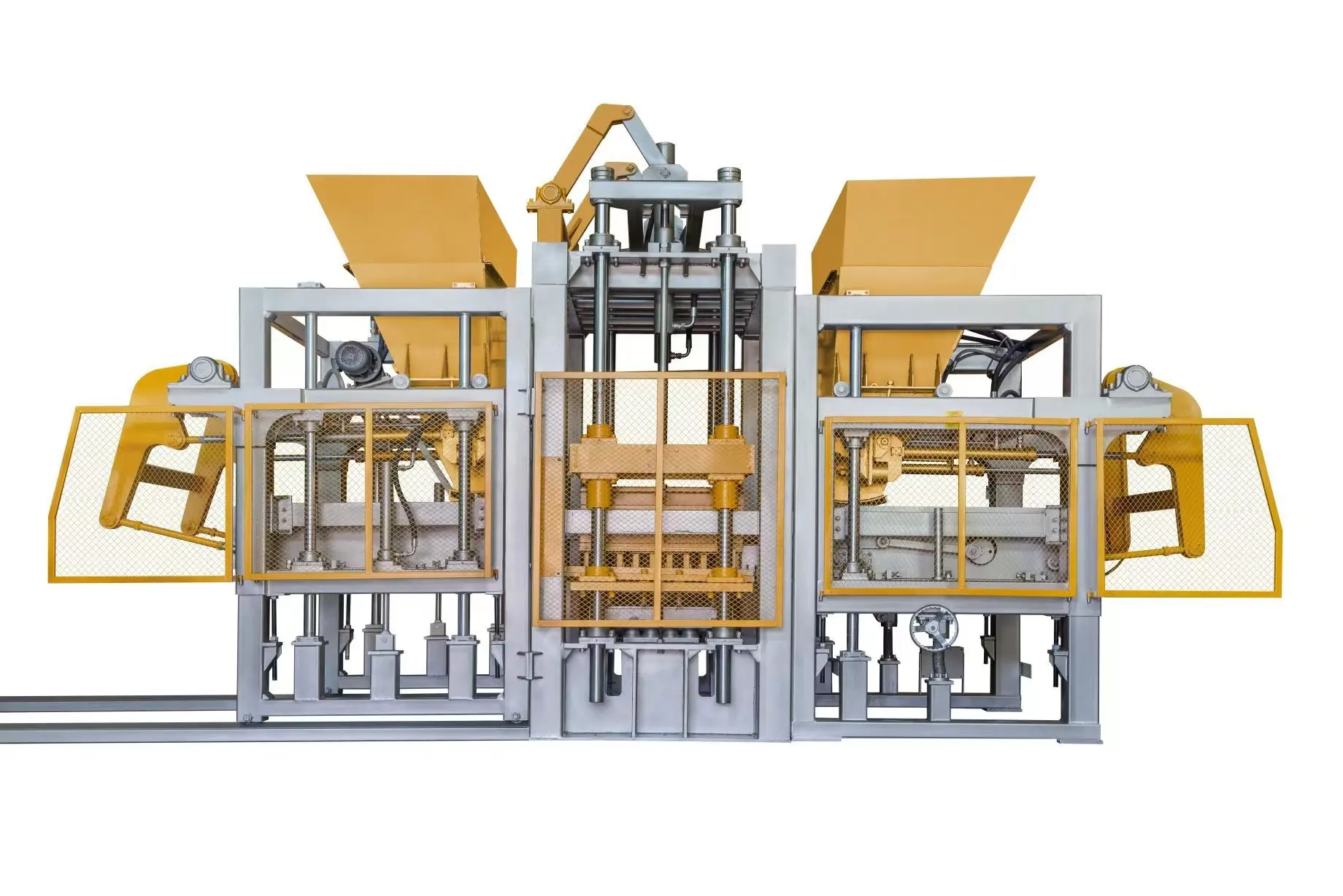

One of the key features of cement bricks hydraulic machines is their hydraulic system, which allows for precise control and consistent pressure during the brick-making process. This ensures uniform bricks with a smooth finish, free of cracks or imperfections. The hydraulic system also allows for adjustable pressure, making it easy to produce different types of bricks with varying strengths and sizes.

In addition to the hydraulic system, these machines also come equipped with advanced automation features that streamline the production process. From mixing the raw materials to molding the bricks to curing and drying, every step is carefully controlled by the machine, reducing the need for manual labor and minimizing the risk of human error. This not only increases efficiency but also improves the quality and consistency of the final product.

Furthermore, cement bricks hydraulic machines are designed with sustainability in mind. They are energy-efficient and produce minimal waste, making them environmentally friendly compared to traditional brick-making methods. By using automated processes that require less manpower and resources, these machines help reduce carbon emissions and minimize the environmental impact of construction projects.

Another advantage of cement bricks hydraulic machines is their versatility. They can be used to produce a wide range of bricks, from standard solid bricks to interlocking bricks, paving stones, and decorative blocks. This versatility makes them ideal for a variety of construction projects, from simple residential buildings to large commercial developments.

Overall, the power of cement bricks hydraulic machines lies in their ability to streamline the brick-making process, increase efficiency, and improve the quality of the final product. With innovations in design and technology, these machines are revolutionizing the construction industry and setting new standards for production efficiency and sustainability. As the demand for sustainable and cost-effective building materials continues to grow, cement bricks hydraulic machines are poised to become an essential tool for construction companies looking to stay ahead of the curve.

- The Future of Construction: Harnessing the Power of Hydraulic Machines

The construction industry has seen remarkable advancements in recent years, thanks to the innovative technologies that are revolutionizing the way we build. One such technology that is changing the game in construction is the cement bricks hydraulic machine. These powerful machines are paving the way for a more efficient, cost-effective, and sustainable future of construction.

Hydraulic machines are essentially tools that run on hydraulic power, which is generated by pressurized fluid. In the case of cement bricks hydraulic machines, this power is used to compress and mold cement, sand, and other materials into sturdy bricks that are essential for building structures. These machines are capable of producing a large quantity of bricks in a short amount of time, making them incredibly efficient and productive compared to traditional brick-making methods.

One of the key advantages of using cement bricks hydraulic machines is their ability to create uniform bricks of consistent quality. This is crucial in construction, where structural integrity and durability are paramount. By using these machines, builders can ensure that every brick meets the necessary standards, reducing the risk of errors and ensuring a more secure and stable structure.

Additionally, cement bricks hydraulic machines are also environmentally friendly, as they utilize a more sustainable production process compared to traditional brick-making methods. These machines require less energy and resources to operate, and can even use recycled materials in the brick-making process. This not only reduces waste but also helps to lower the carbon footprint of construction projects, making them more eco-friendly and in line with sustainable building practices.

Furthermore, the use of cement bricks hydraulic machines can significantly speed up the construction process. With the ability to produce large quantities of bricks in a fraction of the time it would take using traditional methods, builders can complete projects more quickly and efficiently. This not only saves time and money but also allows for faster delivery of much-needed infrastructure and housing developments.

In conclusion, the future of construction is bright with the harnessing of the power of cement bricks hydraulic machines. These innovative tools are revolutionizing the way we build, offering a more efficient, cost-effective, and sustainable solution for construction projects. By utilizing these machines, builders can create high-quality bricks, reduce waste, lower their carbon footprint, and accelerate the construction process. With the continued advancements in technology, it is clear that cement bricks hydraulic machines will play a crucial role in shaping the future of construction for years to come.

Conclusion

In conclusion, the advancement of cement bricks hydraulic machines has truly revolutionized the construction industry. With 18 years of experience in the field, our company has witnessed first-hand the game-changing impact these machines have had on construction processes. From increased efficiency and cost-effectiveness to improved quality and sustainability, the power of these machines cannot be understated. As we move forward, we are excited to continue pushing the boundaries of innovation in construction, and we look forward to the future advancements that will further shape the industry for years to come.