The Ultimate Guide To Choosing The Best Block Bricks Making Machine

Are you in the market for a reliable and efficient block bricks making machine but not sure where to start? Look no further! Our comprehensive guide will walk you through everything you need to know to make the best choice for your business. From key features to consider to expert tips on selecting the right machine for your needs, this ultimate guide has got you covered. Read on to learn more and make an informed decision for your block bricks production.

- Understanding the importance of choosing the right block bricks making machine

Block bricks making machines are essential tools in the construction industry, allowing for the efficient production of high-quality bricks for building projects. However, choosing the right block bricks making machine is crucial to ensuring the success of your construction project. In this ultimate guide, we will delve into the importance of selecting the best block bricks making machine and provide you with valuable tips on how to make an informed decision.

When it comes to choosing a block bricks making machine, there are several factors to consider. The first consideration is the type of bricks you need to produce. Different block bricks making machines are designed to produce different types of bricks, such as solid bricks, hollow bricks, interlocking bricks, and paving stones. It is important to select a machine that is capable of producing the specific type of bricks you require for your project.

Another important factor to consider when selecting a block bricks making machine is the production capacity. The production capacity of a block bricks making machine determines how many bricks can be produced in a given time period. It is crucial to choose a machine with a production capacity that meets the demands of your construction project. Selecting a machine with a higher production capacity than you need can result in wasted resources, while choosing a machine with a lower production capacity can lead to delays in your construction project.

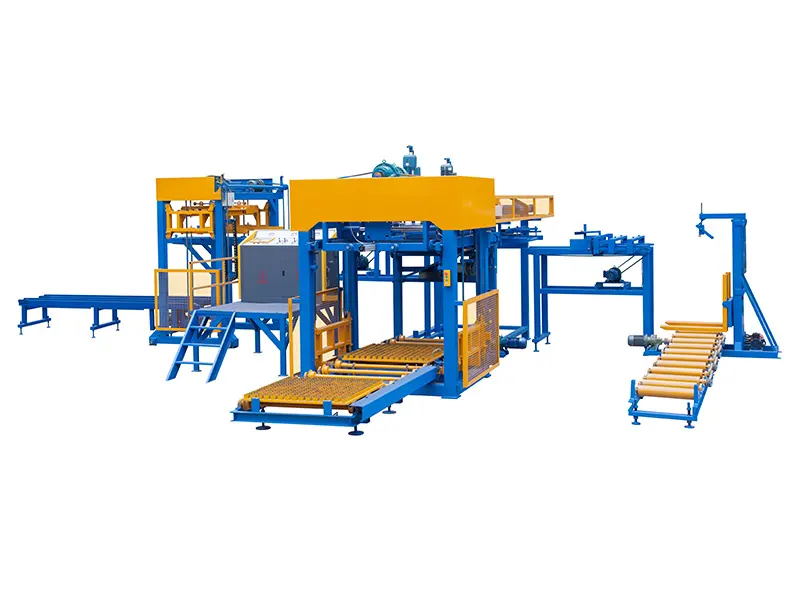

In addition to production capacity, it is also important to consider the size and weight of the block bricks making machine. The size of the machine should be compatible with the available space in your construction site, while the weight of the machine should be manageable for transportation and operation. It is essential to choose a machine that is easy to move and operate to ensure the efficiency of your construction project.

Furthermore, the quality and durability of the block bricks making machine are crucial factors to consider. A high-quality machine will produce bricks that meet the required standards for strength and durability, ensuring the longevity of your building project. It is important to choose a machine from a reputable manufacturer that uses high-quality materials and ensures rigorous quality control measures.

Finally, considering the cost of the block bricks making machine is essential to staying within your budget. While it is important to invest in a high-quality machine, it is also crucial to find a machine that offers the best value for money. Comparing prices from different manufacturers and considering the long-term costs of maintenance and operation will help you make an informed decision.

In conclusion, choosing the right block bricks making machine is a critical step in ensuring the success of your construction project. By considering factors such as the type of bricks, production capacity, size and weight, quality and durability, and cost, you can select a machine that meets your specific needs and budget. With the information provided in this ultimate guide, you can confidently choose the best block bricks making machine for your construction project and achieve excellent results.

- Factors to consider when selecting a block bricks making machine

When it comes to selecting the best block bricks making machine, there are several factors that need to be taken into consideration. Choosing the right machine is crucial for ensuring the quality and efficiency of your brick production process. In this ultimate guide, we will discuss the key factors that you need to keep in mind when choosing a block bricks making machine.

One of the first factors to consider is the production capacity of the machine. The production capacity of a block bricks making machine is typically measured in terms of the number of bricks it can produce per hour. It is important to choose a machine that has a production capacity that meets your needs and demands. If you have a high volume of production, you may need to invest in a machine with a higher production capacity.

Another important factor to consider is the type of bricks that the machine is capable of producing. Some block bricks making machines are designed to produce specific types of bricks, such as solid bricks, hollow bricks, or interlocking bricks. It is essential to choose a machine that can produce the type of bricks that you require for your construction project.

The quality of the bricks produced by the machine is also a crucial factor to consider. The durability and strength of the bricks will depend on the quality of the machine and the materials used in the production process. It is important to choose a machine that is made of high-quality materials and is built to last. Additionally, the machine should be capable of producing bricks that meet the required quality standards.

The automation and technology used in the machine is another important factor to consider. Some block bricks making machines are fully automated, while others require manual operation. Automated machines are more efficient and can produce bricks faster, but they may also be more expensive. It is important to weigh the benefits of automation against the cost to determine the best option for your needs.

The size and footprint of the machine are also factors that need to be taken into consideration. Depending on the available space in your production facility, you may need to choose a machine that has a small footprint. It is essential to ensure that the machine can be installed and operated within the space constraints of your facility.

In conclusion, choosing the best block bricks making machine requires careful consideration of several factors, including production capacity, type of bricks produced, quality of bricks, automation and technology, and machine size. By keeping these factors in mind, you can select a machine that meets your production requirements and helps you achieve the desired quality of bricks for your construction projects.

- Comparing different types of block bricks making machines

Block bricks making machines are essential equipment for those in the construction industry looking to produce high-quality bricks efficiently and cost-effectively. With various types of block bricks making machines available on the market, choosing the best one for your needs can be a daunting task. In this ultimate guide, we will compare different types of block bricks making machines to help you make an informed decision.

One of the key factors to consider when choosing a block bricks making machine is the production capacity. The production capacity of a machine is typically measured in terms of the number of bricks it can produce in a certain period of time. Higher production capacity machines are ideal for larger construction projects, while lower production capacity machines may be more suitable for smaller projects.

Another important factor to consider is the type of bricks that can be produced by the machine. Different block bricks making machines are designed to produce different types of bricks, such as solid bricks, hollow bricks, and interlocking bricks. Depending on your specific requirements, you may need a machine that can produce a certain type of brick or a machine that can produce multiple types of bricks.

Additionally, the size and weight of the block bricks making machine are important considerations, especially if you have limited space in your construction site. Smaller and lighter machines are easier to transport and maneuver, while larger and heavier machines may require more space and manpower to operate.

Furthermore, it is important to consider the cost of the block bricks making machine. The price of a machine can vary depending on its production capacity, features, and brand. It is essential to choose a machine that fits within your budget while still meeting your production needs.

In terms of technology, some block bricks making machines come equipped with advanced features such as automatic brick stacking and palletizing, which can improve efficiency and reduce labor costs. These features may be worth considering if you are looking to streamline your brick production process.

When comparing different types of block bricks making machines, it is also important to consider the reputation and reliability of the manufacturer. Choose a reputable manufacturer with a track record of producing high-quality machines that are built to last.

In conclusion, choosing the best block bricks making machine for your needs requires careful consideration of factors such as production capacity, types of bricks produced, size and weight, cost, technology, and manufacturer reputation. By comparing different types of block bricks making machines based on these factors, you can make an informed decision that will help you produce high-quality bricks efficiently and cost-effectively.

- Tips for determining the best block bricks making machine for your needs

Block bricks making machines are an essential piece of equipment for any construction project that involves the production of concrete blocks. Whether you are a DIY enthusiast or a professional builder, choosing the right block bricks making machine is crucial for the success of your project. With so many options available in the market, it can be overwhelming to determine which machine is the best fit for your needs. In this ultimate guide, we will provide you with tips on how to choose the best block bricks making machine for your specific requirements.

The first step in selecting the right block bricks making machine is to determine the size and capacity that you need. Consider the scale of your project and the frequency at which you will be producing blocks. Machines come in a range of sizes, from small manual machines suitable for DIY projects to large industrial machines capable of producing thousands of blocks per day. It is important to choose a machine that can meet your production requirements without being overly large and expensive.

Another important factor to consider when choosing a block bricks making machine is the type of blocks you will be producing. Different machines are designed to produce different types of blocks, such as solid blocks, hollow blocks, interlocking blocks, etc. Make sure to choose a machine that is specifically designed for the type of blocks you need for your project. Some machines also have the ability to produce different types of blocks by simply changing the moulds, providing versatility and flexibility.

In addition to size and type of blocks, you should also consider the technology and features of the machine. Modern block bricks making machines come equipped with a range of features such as automatic operation, hydraulic systems, and energy-saving capabilities. These features can improve efficiency, reduce labor costs, and ultimately increase the quality of your blocks. Consider your budget and the specific requirements of your project when selecting a machine with the right technology and features.

When buying a block bricks making machine, it is also important to consider the reputation and reliability of the manufacturer. Look for well-established brands with a track record of producing high-quality machines that are durable and long-lasting. Read reviews and testimonials from other customers to get an idea of the manufacturer's reputation and customer satisfaction. Investing in a machine from a reputable manufacturer may cost more upfront but will save you money in the long run by avoiding frequent breakdowns and repairs.

In conclusion, choosing the best block bricks making machine for your needs requires careful consideration of size, type of blocks, technology, features, and manufacturer reputation. By following the tips outlined in this guide, you can make an informed decision that will ensure the success of your construction project. Remember that the right machine will not only improve the efficiency of your production process but also the quality of your blocks. Choose wisely and invest in a machine that meets your specific requirements to achieve the desired results.

- Conclusion: making an informed decision for your block bricks making machine

When it comes to choosing the best block bricks making machine for your needs, there are several factors to consider in order to make an informed decision. In this ultimate guide, we have covered everything you need to know about selecting the right machine for your block bricks production.

First and foremost, it is important to assess the production capacity of the block bricks making machine. This will depend on the size of your project and the quantity of blocks you need to produce. Consider the number of bricks the machine can produce per hour and whether it meets your production requirements.

Another crucial factor to consider is the type of bricks the machine can produce. Some machines are designed for specific types of blocks, such as hollow, solid, or paving bricks. Make sure the machine you choose is capable of producing the type of bricks you need for your project.

In addition to production capacity and type of bricks, it is also important to consider the quality of the blocks produced by the machine. Look for machines that are known for producing high-quality, durable blocks that meet industry standards. This will ensure that your finished product is strong and long-lasting.

When selecting a block bricks making machine, it is also important to consider the cost of the machine and the overall return on investment. Compare prices from different manufacturers and consider factors such as maintenance costs, energy efficiency, and warranty options. It is important to choose a machine that offers a good balance of quality and affordability.

Furthermore, consider the ease of use and maintenance of the machine. Look for machines that are user-friendly and easy to operate, with clear instructions and minimal downtime for maintenance. A machine that is easy to maintain will help ensure smooth production and minimize disruptions to your project.

Lastly, consider the reputation and reliability of the manufacturer when choosing a block bricks making machine. Look for manufacturers with a solid track record of producing quality machines and providing excellent customer service. Read reviews and testimonials from other customers to get a sense of the manufacturer's reputation in the industry.

In conclusion, choosing the best block bricks making machine for your project requires careful consideration of several factors, including production capacity, type of bricks produced, quality, cost, ease of use, and manufacturer reputation. By making an informed decision based on these factors, you can ensure that you select a machine that meets your production needs and delivers high-quality blocks for your project.

Conclusion

In conclusion, choosing the best block bricks making machine is a crucial decision for any construction business. With 18 years of experience in the industry, our company has compiled the ultimate guide to help you make an informed choice. By considering factors such as production capacity, automation features, and durability, you can ensure that you select a machine that meets your specific needs and requirements. Investing in the right block bricks making machine will not only improve the efficiency of your operations but also contribute to the overall success of your projects. Make the right choice today and watch your business thrive.