The Ultimate Guide To Choosing The Best Interlocking Block Making Machine

Are you in the market for the perfect interlocking block making machine but feeling overwhelmed by the options? Look no further! Our comprehensive guide is here to help you navigate the countless options available and choose the best interlocking block making machine for your needs. From understanding the key features to considering your budget, we have got you covered every step of the way. Read on to find out everything you need to know to make an informed decision and start your next construction project with confidence.

- Understanding the Different Types of Interlocking Block Making Machines

Interlocking block making machines have revolutionized the construction industry with their ability to create durable and eco-friendly building blocks. However, with a wide variety of machines available on the market, it can be overwhelming to choose the best one for your needs. In this comprehensive guide, we will delve into the different types of interlocking block making machines to help you make an informed decision.

The first type of interlocking block making machine is the manual machine. These machines require human labor to operate and produce blocks of varying sizes and shapes. While they are more affordable than automated machines, manual machines are labor-intensive and may not be suitable for large-scale projects.

Next, we have semi-automatic interlocking block making machines. These machines combine manual labor with automated processes to increase production efficiency. They are ideal for small to medium-sized projects and offer a good balance between cost and output.

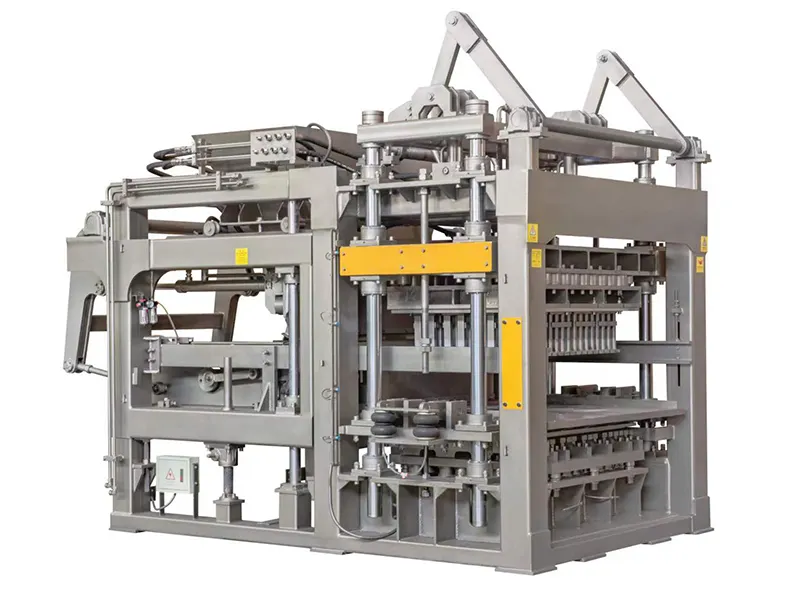

On the other end of the spectrum are fully automatic interlocking block making machines. These machines are fully automated, requiring minimal human intervention. They are capable of producing a high volume of blocks in a short amount of time, making them perfect for large-scale construction projects.

Another important factor to consider when choosing an interlocking block making machine is the type of blocks it can produce. Some machines are designed to create standard interlocking blocks, while others can also produce hollow blocks, paving stones, and other specialized blocks. It is essential to determine the type of blocks you need for your project before selecting a machine.

Additionally, the size and capacity of the machine are crucial considerations. Machines come in various sizes and production capacities, so it is important to choose one that can meet the demands of your project. Consider factors such as the size of your construction site, the volume of blocks required, and your budget when selecting a machine.

Furthermore, the quality of the blocks produced by the machine is paramount. Look for machines that are durable, reliable, and capable of producing high-quality blocks that meet industry standards. A well-built machine will ensure the longevity of your construction project and minimize maintenance costs in the long run.

In conclusion, choosing the best interlocking block making machine requires careful consideration of the types of machines available, the blocks they can produce, their size and capacity, and the quality of their output. By understanding the different types of machines and their features, you can make an informed decision that will ensure the success of your construction project.

- Factors to Consider When Choosing the Best Interlocking Block Making Machine

When it comes to choosing the best interlocking block making machine for your construction needs, there are several factors that should be taken into consideration. These factors can have a significant impact on the efficiency, reliability, and overall performance of the machine, so it is important to carefully evaluate each one before making a decision.

One of the most important factors to consider when choosing an interlocking block making machine is the production capacity. This refers to the number of blocks that the machine can produce in a given period of time, and it is crucial to ensure that the machine can keep up with the demands of your project. If you are working on a large-scale construction project, you will likely need a machine with a high production capacity to meet your needs efficiently.

Another important factor to consider is the quality of the blocks produced by the machine. The blocks should be uniform in size and shape, with smooth surfaces and consistent strength. It is important to choose a machine that can produce high-quality blocks consistently, as this will not only ensure the structural integrity of your construction project but also save time and money by reducing the need for rework or repairs.

The ease of operation and maintenance of the interlocking block making machine is also a key factor to consider. The machine should be user-friendly, with intuitive controls and clear instructions for operation. Additionally, it should be easy to clean and maintain to ensure optimal performance and longevity. Choosing a machine that is easy to operate and maintain can save time and effort in the long run, making it a worthwhile investment.

The cost of the interlocking block making machine is another important consideration. While it is important to choose a machine that fits within your budget, it is also important to consider the long-term costs associated with the machine. This includes factors such as energy efficiency, maintenance costs, and the cost of replacement parts. It is important to weigh the initial cost of the machine against these long-term costs to ensure that you are getting the best value for your money.

Finally, it is important to consider the reputation of the manufacturer when choosing an interlocking block making machine. Look for a manufacturer with a good track record of producing high-quality machines that are reliable and durable. Reading reviews and testimonials from other customers can help you gauge the reputation of a manufacturer and make an informed decision.

In conclusion, choosing the best interlocking block making machine requires careful consideration of factors such as production capacity, block quality, ease of operation and maintenance, cost, and manufacturer reputation. By carefully evaluating these factors, you can ensure that you choose a machine that meets your construction needs efficiently and effectively.

- Evaluating the Production Capacity and Efficiency of Interlocking Block Making Machines

Interlocking block making machines are becoming increasingly popular in the construction industry due to their efficiency and cost-effectiveness. When choosing the best interlocking block making machine, it is important to consider various factors, including the production capacity and efficiency of the machine.

Production capacity is a key factor to consider when evaluating interlocking block making machines. This refers to the maximum number of blocks that the machine can produce in a given time period. Machines with higher production capacities are able to produce more blocks in a shorter amount of time, which can help increase efficiency and reduce overall construction time.

Efficiency is another important factor to consider when choosing an interlocking block making machine. Efficiency refers to how well the machine is able to convert raw materials into finished blocks. Machines that are more efficient will waste fewer materials and require less manpower to operate, ultimately saving time and money in the long run.

When evaluating the production capacity and efficiency of interlocking block making machines, it is important to consider the specific needs of your construction project. For smaller projects, a machine with a lower production capacity may be sufficient, while larger projects may require a machine with a higher capacity.

In addition to production capacity and efficiency, it is also important to consider the durability and reliability of the machine. A well-built machine that is made from high-quality materials will last longer and require less maintenance, saving you time and money in the long run.

When researching different interlocking block making machines, be sure to read reviews and testimonials from other users to get a sense of the machine's performance in real-world construction projects. You can also contact the manufacturer directly to ask any specific questions you may have about the machine's production capacity and efficiency.

In conclusion, choosing the best interlocking block making machine requires careful consideration of factors such as production capacity, efficiency, durability, and reliability. By evaluating these factors and doing thorough research, you can ensure that you select a machine that meets the needs of your construction project and helps you achieve your building goals efficiently and cost-effectively.

- Exploring the Cost and Maintenance of Interlocking Block Making Machines

Interlocking block making machines have become an essential tool for construction projects around the world. These machines are designed to produce interlocking blocks that can be used to build sturdy and durable structures. In this ultimate guide, we will delve into the cost and maintenance considerations that you should keep in mind when choosing the best interlocking block making machine for your needs.

Cost is a crucial factor to consider when purchasing an interlocking block making machine. These machines come in a wide range of prices, depending on their size, capacity, and features. It is important to determine your budget and requirements before making a decision. Keep in mind that investing in a high-quality machine may initially be more expensive, but it can save you money in the long run by reducing maintenance and repair costs.

When comparing the cost of different interlocking block making machines, it is important to consider not only the upfront price but also the operational costs. Look for machines that are energy-efficient and have low maintenance requirements to minimize your expenses over time. Additionally, consider the availability and cost of spare parts, as this can impact the overall cost of ownership.

Maintenance is another crucial aspect to consider when choosing an interlocking block making machine. Regular maintenance is essential to ensure that the machine operates efficiently and produces high-quality blocks. Before purchasing a machine, inquire about the manufacturer's recommended maintenance schedule and procedures. Make sure that you have access to a reliable service provider who can perform maintenance and repairs as needed.

Some key maintenance tasks for interlocking block making machines include cleaning and lubricating the machine regularly, inspecting and replacing worn parts, and calibrating the machine to ensure accurate block production. Proper maintenance not only extends the lifespan of the machine but also helps prevent breakdowns and costly repairs.

In conclusion, choosing the best interlocking block making machine involves considering both the cost and maintenance aspects. By carefully evaluating your budget, operational costs, and maintenance requirements, you can select a machine that meets your needs and provides long-term value. Keep in mind that investing in a high-quality machine and following a proactive maintenance routine can help you achieve optimal performance and efficiency in your construction projects.

- Tips for Selecting the Right Interlocking Block Making Machine for Your Needs

Interlocking block making machines have revolutionized the construction industry, making it easier and more cost-effective to produce durable and stable blocks for building projects. However, with so many options available on the market, it can be overwhelming to choose the right machine for your specific needs. In this ultimate guide, we will provide you with valuable tips on how to select the best interlocking block making machine for your requirements.

1. Determine your production capacity: One of the key factors to consider when choosing an interlocking block making machine is your production capacity. Are you a small-scale contractor looking to produce blocks for a specific project, or are you a larger company with high-volume production requirements? Understanding your production capacity will help you select a machine that can meet your needs without overstretching your budget.

2. Consider the size and shape of the blocks: Interlocking block making machines come in different sizes and configurations, each capable of producing a specific size and shape of block. Before making a purchase, it is essential to consider the size and shape of the blocks you need for your project. Some machines are better suited for larger blocks, while others are designed for smaller, more intricate designs.

3. Evaluate the quality of the blocks: The quality of the blocks produced by an interlocking block making machine is crucial for the success of your construction project. Look for machines that are known for producing high-quality blocks that are durable, stable, and free from defects. Read reviews from other customers and consider visiting manufacturers' facilities to see the machines in action before making a decision.

4. Assess the level of automation: Interlocking block making machines come in a range of automation levels, from manual machines that require more labor and time to fully automated machines that can produce blocks with minimal human intervention. Consider your team's skills and resources when deciding on the level of automation that is right for your project. While fully automated machines may be more expensive upfront, they can save time and labor costs in the long run.

5. Look for additional features: In addition to the basic functions of block production, some interlocking block making machines come with additional features that can enhance productivity and efficiency. Look for machines that offer features such as block stacking systems, mold customization options, and remote monitoring capabilities. These additional features can help you maximize the potential of your machine and improve overall project outcomes.

In conclusion, selecting the right interlocking block making machine for your needs requires careful consideration of your production capacity, block size and shape requirements, block quality expectations, level of automation, and additional features. By following the tips outlined in this guide, you can confidently choose the best machine for your construction projects and ensure successful outcomes every time.

Conclusion

In conclusion, choosing the best interlocking block making machine is a crucial decision that can have a significant impact on your business. With 18 years of experience in the industry, our company is well-equipped to help you make an informed decision. By following the tips and considerations outlined in this ultimate guide, you can ensure that you select a machine that meets your needs and helps you achieve success in your block making endeavors. Remember, investing in a high-quality machine is an investment in the future of your business. Choose wisely and watch your profits soar.