The Ultimate Guide To Industrial Brick Making Machines: Features, Benefits, And Machinery Tips

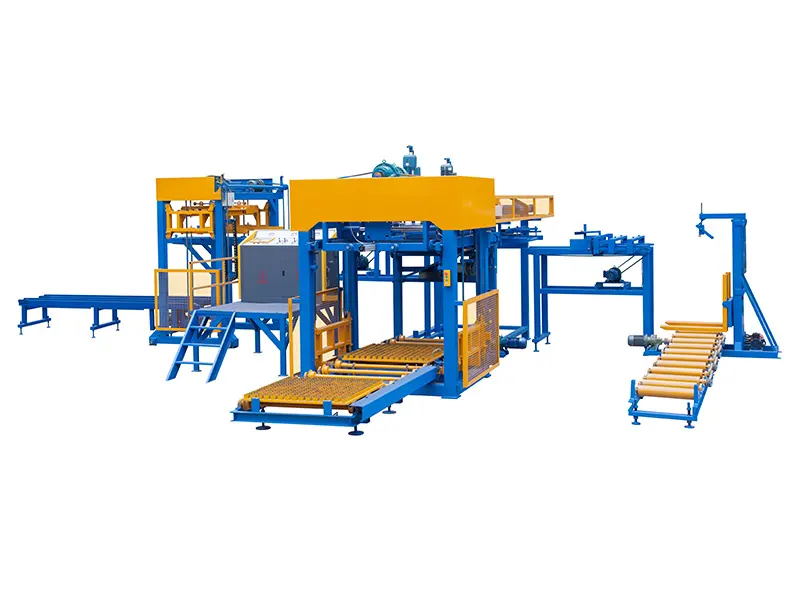

Are you looking to take your brick making business to the next level? Look no further than our ultimate guide to industrial brick making machines. Packed with valuable information on features, benefits, and machinery tips, this comprehensive resource is a must-read for any brick making enthusiast. Whether you're a seasoned professional or just starting out, this guide has everything you need to succeed in the competitive world of brick manufacturing. Dive in and discover how you can maximize efficiency, reduce costs, and boost productivity with the latest industrial brick making machines.

Selecting the Right Industrial Brick Making Machine

When it comes to selecting the right industrial brick making machine for your business, there are a few key factors to consider. Industrial brick making machines are essential for manufacturing bricks on a large scale, whether for construction projects or for sale to other businesses. In this ultimate guide, we will cover the features, benefits, and machinery tips that you need to know in order to choose the best industrial brick making machine for your needs.

One of the first things to consider when selecting an industrial brick making machine is the capacity. Different machines have different production capacities, ranging from a few hundred bricks per hour to thousands of bricks per hour. The capacity you need will depend on the scale of your operation and the demand for bricks in your market. It's important to choose a machine that can meet your production goals without being overkill.

Another important factor to consider is the type of bricks that the machine is capable of producing. Some industrial brick making machines are designed specifically for certain types of bricks, such as solid bricks, hollow bricks, or interlocking bricks. It's important to choose a machine that can produce the specific type of bricks that you need for your projects.

In addition to capacity and brick type, it's also important to consider the overall quality and reliability of the machine. Look for a machine that is built with high-quality materials and components, as this will ensure that it is durable and long-lasting. A reliable machine will also help to minimize downtime and maintenance costs, which can have a significant impact on your bottom line.

When it comes to the benefits of investing in an industrial brick making machine, there are several key advantages to consider. One of the biggest benefits is the ability to produce bricks on a large scale, which can help to increase efficiency and reduce labor costs. Industrial brick making machines can also produce bricks that are more uniform in size and shape, which can improve the overall quality of your products.

Another benefit of investing in an industrial brick making machine is the potential for increased profits. By producing bricks in-house, you can save on the cost of purchasing bricks from suppliers, which can help to increase your profit margins. Additionally, by producing bricks on a large scale, you can take advantage of economies of scale, which can further reduce your production costs.

In terms of machinery tips, it's important to ensure that your industrial brick making machine is properly maintained and serviced on a regular basis. Regular maintenance can help to prevent breakdowns and extend the lifespan of the machine. It's also important to train your staff on how to operate the machine safely and efficiently, as proper training can help to maximize productivity and minimize the risk of accidents.

In conclusion, selecting the right industrial brick making machine is essential for any business that is looking to produce bricks on a large scale. By considering factors such as capacity, brick type, quality, and reliability, you can choose a machine that meets your production goals and helps to increase efficiency and profitability. With the right machine in place, you can take your brick production to the next level and achieve success in the competitive brick-making industry.

Exploring the Features of Industrial Brick Making Machines

Industrial brick making machines are essential tools for any construction business looking to produce large volumes of bricks efficiently. These machines come equipped with a range of features that make the brick making process faster, more cost-effective, and less labor-intensive. In this comprehensive guide, we will delve into the various features of industrial brick making machines, their benefits, and provide some useful machinery tips for maximizing their productivity.

One of the key features of industrial brick making machines is their high capacity production capabilities. These machines are capable of producing thousands of bricks per hour, allowing construction companies to meet tight deadlines and fulfill large orders with ease. Additionally, industrial brick making machines are highly automated, reducing the need for manual labor and ensuring consistent brick quality.

Another important feature of industrial brick making machines is their versatility. These machines can produce a variety of brick sizes and shapes, allowing construction businesses to cater to different project requirements. Whether you need standard bricks, interlocking bricks, or even specialized shapes, an industrial brick making machine can deliver.

Industrial brick making machines are also equipped with advanced technology that improves efficiency and reduces waste. Many machines come with features such as automatic brick stacking, brick molding, and even self-cleaning mechanisms. This not only streamlines the brick making process but also minimizes downtime and maintenance costs.

In terms of benefits, industrial brick making machines offer a range of advantages for construction businesses. Firstly, these machines significantly reduce production costs by cutting down on labor expenses and increasing productivity. This leads to higher profit margins and better competitiveness in the market.

Moreover, industrial brick making machines produce bricks of consistent quality, ensuring the structural integrity of buildings and reducing the risk of defects or failures. This, in turn, enhances the reputation of the construction business and instills confidence in clients.

To maximize the productivity of industrial brick making machines, it is important to adhere to some machinery tips. Regular maintenance and cleaning are crucial to keeping the machine in optimal condition and preventing breakdowns. Additionally, proper training for operators can help improve efficiency and reduce errors in the brick making process.

In conclusion, industrial brick making machines are indispensable tools for construction businesses looking to streamline their brick production process. With their high capacity production capabilities, versatility, and advanced technology, these machines offer a range of benefits that can significantly boost efficiency and profitability. By following some key machinery tips, businesses can make the most of their industrial brick making machines and ensure smooth operations for their construction projects.

Unlocking the Benefits of Using Industrial Brick Making Machines

Industrial brick making machines are essential equipment for any construction project that requires a large number of bricks. These machines are highly efficient and can produce bricks at a much faster rate than traditional methods, making them ideal for commercial and industrial applications.

One of the key benefits of using industrial brick making machines is the cost savings. These machines are able to produce bricks in large quantities, which can help reduce the overall cost of a construction project. Additionally, the use of industrial brick making machines can also help to reduce the amount of labor required, further cutting down on costs.

Another major benefit of using industrial brick making machines is the quality of the bricks produced. These machines are able to produce bricks that are consistent in size and shape, which is essential for creating a professional finish on any construction project. Additionally, industrial brick making machines are able to produce bricks that are stronger and more durable than those made using traditional methods, ensuring that the final product is able to withstand the test of time.

In addition to cost savings and improved quality, industrial brick making machines also offer a number of other benefits. For example, these machines are able to produce bricks much faster than traditional methods, allowing for quicker completion of construction projects. This can help to reduce overall project timelines, allowing for projects to be completed more quickly and efficiently.

Furthermore, industrial brick making machines are able to be customized to meet the specific needs of any construction project. These machines can be adjusted to produce different sizes and shapes of bricks, making them incredibly versatile and adaptable. This flexibility can help to ensure that the final product meets the exact specifications required for the project.

When it comes to machinery tips for using industrial brick making machines, it is important to ensure that the machines are properly maintained and serviced regularly. This can help to prevent breakdowns and ensure that the machines are able to operate at peak efficiency. Additionally, it is important to train operators on how to use the machines safely and effectively, in order to prevent accidents and prolong the lifespan of the equipment.

Overall, industrial brick making machines offer a wide range of benefits for construction projects. From cost savings and improved quality to increased efficiency and versatility, these machines are a valuable addition to any construction site. By unlocking the benefits of using industrial brick making machines, construction companies can improve the overall success of their projects and create high-quality, durable structures that stand the test of time.

Proper Maintenance and Machinery Tips for Industrial Brick Making Machines

Industrial brick making machines are essential equipment for manufacturers in the construction industry. These machines are designed to produce large quantities of bricks efficiently and effectively, making them a valuable asset for any brick-making business. In this article, we will discuss the proper maintenance and machinery tips for industrial brick making machines, highlighting the features and benefits that make them essential for modern construction projects.

Proper maintenance is crucial for ensuring the longevity and efficiency of industrial brick making machines. Regular maintenance routines should include cleaning, lubricating, and inspecting the machine for any signs of wear or damage. It is also important to follow the manufacturer's guidelines for maintenance and to schedule regular service checks to keep the machine running smoothly.

One of the key machinery tips for industrial brick making machines is to invest in high-quality materials and components. Using low-quality materials can result in poor-quality bricks and lead to more frequent breakdowns and repairs. It is important to choose a machine that is made from durable materials and has a reliable construction to ensure consistent performance and longevity.

Another important machinery tip for industrial brick making machines is to ensure proper training for operators. Proper training will help operators understand how to operate the machine safely and efficiently, reducing the risk of accidents and improving productivity. It is also important to provide ongoing training to keep operators up to date on the latest techniques and best practices for operating the machine.

Industrial brick making machines come with a range of features and benefits that make them essential for modern construction projects. These machines are designed to produce bricks quickly and in large quantities, helping construction companies meet tight deadlines and project schedules. They also offer consistent quality and precision, ensuring that every brick meets industry standards and specifications.

In addition, industrial brick making machines are highly versatile and can be customized to meet the specific needs of different construction projects. They can produce different sizes and shapes of bricks, as well as other building materials such as pavers and tiles, making them a valuable asset for any construction business. With the right machine, manufacturers can increase their production capacity and expand their product range, positioning themselves as industry leaders in the competitive construction market.

In conclusion, industrial brick making machines are essential equipment for manufacturers in the construction industry. Proper maintenance and machinery tips are crucial for ensuring the longevity and efficiency of these machines. By following best practices and investing in high-quality materials and training for operators, manufacturers can maximize the benefits of industrial brick making machines and stay ahead of the competition in the construction market.

Maximizing Efficiency in Brick Production with Industrial Machinery

Industrial brick making machines have revolutionized the process of brick production, maximizing efficiency and increasing productivity in the construction industry. These powerful machines play a crucial role in speeding up the production of bricks and ensuring consistent quality throughout the manufacturing process. In this ultimate guide, we will delve into the features, benefits, and machinery tips related to industrial brick making machines.

Features of Industrial Brick Making Machines:

Industrial brick making machines are equipped with advanced technology and innovative features to streamline the brick production process. Some key features that set these machines apart include:

1. Automated Brick Molding: Industrial brick making machines are capable of automatically molding bricks in various sizes and shapes, reducing the need for manual labor and increasing efficiency.

2. High Production Capacity: These machines have a high production capacity, allowing manufacturers to produce a large number of bricks in a shorter period of time.

3. Precision Control: Industrial brick making machines offer precise control over the manufacturing process, ensuring consistent quality and uniformity in the bricks produced.

4. Durable Construction: These machines are built to withstand the rigors of continuous operation, with sturdy construction and high-quality materials.

5. Easy Maintenance: Industrial brick making machines are designed for easy maintenance and repair, minimizing downtime and ensuring smooth operation.

Benefits of Industrial Brick Making Machines:

The use of industrial brick making machines offers a plethora of benefits to manufacturers in the construction industry:

1. Increased Efficiency: Industrial brick making machines streamline the production process, reducing labor costs and increasing overall efficiency.

2. Consistent Quality: These machines ensure consistent quality in the bricks produced, leading to improved reliability and durability in construction projects.

3. Cost Savings: By automating the brick production process, industrial machines help reduce operational costs and increase profitability for manufacturers.

4. Faster Production: Industrial brick making machines enable manufacturers to produce bricks at a faster rate, meeting project deadlines and increasing productivity.

5. Environmental Sustainability: These machines are designed to be energy-efficient and eco-friendly, reducing the carbon footprint of brick manufacturing operations.

Machinery Tips for Maximizing Efficiency:

To make the most of industrial brick making machines, manufacturers can follow these tips for maximizing efficiency:

1. Regular Maintenance: Ensure that the machine is properly maintained and serviced regularly to prevent breakdowns and maximize uptime.

2. Optimize Settings: Adjust the machine settings based on the type of bricks being produced to achieve the desired quality and consistency.

3. Monitor Production: Keep track of production metrics and performance data to identify areas for improvement and optimize the manufacturing process.

4. Invest in Training: Provide training for operators to ensure that they are proficient in using the machine and maximizing its capabilities.

5. Stay Updated: Stay informed about the latest advancements in industrial brick making technology to take advantage of new features and improvements.

In conclusion, industrial brick making machines play a crucial role in optimizing efficiency and increasing productivity in the construction industry. By leveraging the features, benefits, and machinery tips outlined in this guide, manufacturers can enhance their brick production process and stay ahead of the competition.

Conclusion

After delving into the features, benefits, and machinery tips of industrial brick making machines, it is clear that these powerful tools are essential for any construction project. With 18 years of experience in the industry, we understand the importance of investing in high-quality equipment to ensure efficiency and productivity. By utilizing these advanced machines, businesses can streamline their production process and create durable bricks for a wide range of applications. As technology continues to advance, we are committed to staying at the forefront of innovation in order to provide our customers with the best possible solutions. With the ultimate guide to industrial brick making machines in hand, businesses can take their production capabilities to new heights and achieve lasting success in the construction industry.